Novel ozone generation system for biological pharmacy

A technology of ozone generation and biopharmaceuticals, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve problems such as shortening the service life of ozone modules, distinguishing complex structures, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

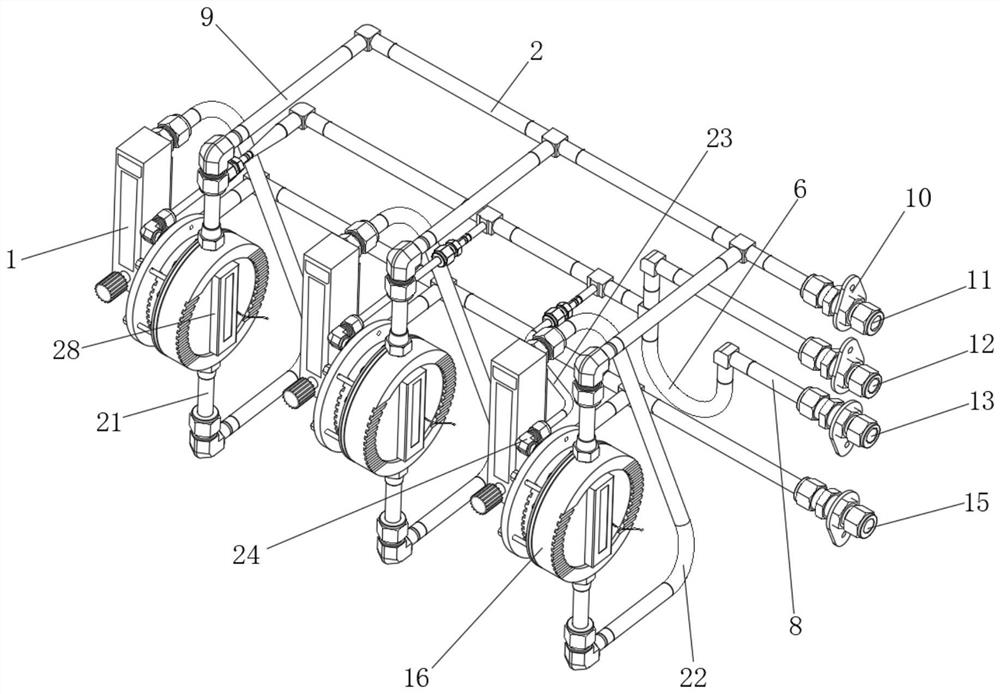

[0044] Embodiment 1: A group of ozone modules 19 are used.

[0045] Ozone module 19 comprises trigger enzyme 17, and the both sides of trigger enzyme 17 are respectively equipped with cathode electrode plate 18 and anode electrode plate 16, and cathode electrode plate 18 and anode electrode plate 16 are interconnected; The top of anode electrode plate 16 is provided with product output The bottom is provided with a water inlet 20, the upper outer part of the cathode electrode plate 18 is provided with a hydrogen and water discharge interface 24, the product output port is vertically installed with an output pipe 14, and the head of the output pipe 14 is installed with a connecting pipe 9 through a 90-degree conversion head. , the head of the communication pipe 9 is connected to the output main pipe 2, and the end of the output main pipe 2 is equipped with a product output joint 11; the hydrogen gas and water discharge interface 24 communicates with the discharge pipe 5 through ...

Embodiment 2

[0046] Embodiment 2: Two groups of ozone modules 19 are used.

[0047] A single ozone module 19 includes a trigger enzyme 17, the two sides of the trigger enzyme 17 are respectively equipped with a cathode electrode plate 18 and an anode electrode plate 16, and the cathode electrode plate 18 and the anode electrode plate 16 are connected to each other;

[0048] The top of the anode electrode plate 16 of each ozone module 19 is provided with a product output port, the bottom is provided with a water inlet 20, and the outer upper part of the cathode electrode plate 18 is provided with a hydrogen and water discharge interface 24, and each product output port is installed vertically There is an output pipe 14, the head of the output pipe 14 is installed with a connecting pipe 9 through a 90-degree conversion head, the head of the connecting pipe 9 is connected to the output main pipe 2, and the end of the output main pipe 2 is equipped with a product output joint 11; each hydrogen ...

Embodiment 3

[0049] Embodiment Three: Three groups of ozone modules 19 are used.

[0050] A single ozone module 19 includes a trigger enzyme 17, the two sides of the trigger enzyme 17 are respectively equipped with a cathode electrode plate 18 and an anode electrode plate 16, and the cathode electrode plate 18 and the anode electrode plate 16 are connected to each other;

[0051] The top of the anode electrode plate 16 of each ozone module 19 is provided with a product output port, the bottom is provided with a water inlet 20, and the outer upper part of the cathode electrode plate 18 is provided with a hydrogen and water discharge interface 24, and each product output port is installed vertically There is an output pipe 14, the head of the output pipe 14 is installed with a connecting pipe 9 through a 90-degree conversion head, the head of the connecting pipe 9 is connected to the output main pipe 2, and the end of the output main pipe 2 is equipped with a product output joint 11; each hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com