Crack-free nickel-based superalloy and component design method and preparation method thereof

A kind of nickel-based superalloy, the technology of composition design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Modified GH3536M alloy composition, by mass percentage: Mo: 10.94%, Cr: 24.96%, W: 1.18%, Co: 4.27%, Fe: 10.55%, C: 0.073%, Mn: 0.61%, Si: 0.3% , and the balance is Ni. The preparation method comprises the following steps:

[0056] S1. Alloy powder preparation:

[0057] 1) Raw material smelting: Weigh the raw material of the intermediate compound metal block according to the proportion of alloy elements and place it in a vacuum induction furnace for heating and melting. The above-mentioned pre-alloyed metal after smelting is transferred into an atomizing tank, and argon gas is used to make powder, and the atomization pressure is about 2.0MPa; 3) Powder screening: the above-mentioned pre-alloyed powder is subjected to a visual screening process to obtain an average particle size of 31.8μm metal powder, the particle size range is 15μm~53μm, the appearance of the modified GH3536 alloy powder is as follows figure 1 4) heat preservation and drying: put the above-mentioned...

Embodiment 2

[0061] Modified GH3536M alloy composition, by mass percentage: Mo: 10.94%, Cr: 24.96%, W: 1.18%, Co: 4.27%, Fe: 10.55%, C: 0.073%, Mn: 0.61%, Si: 0.3% , the balance is Ni; the Md and B of the GH3536M 0 The values are 0.9275 and 0.8598.

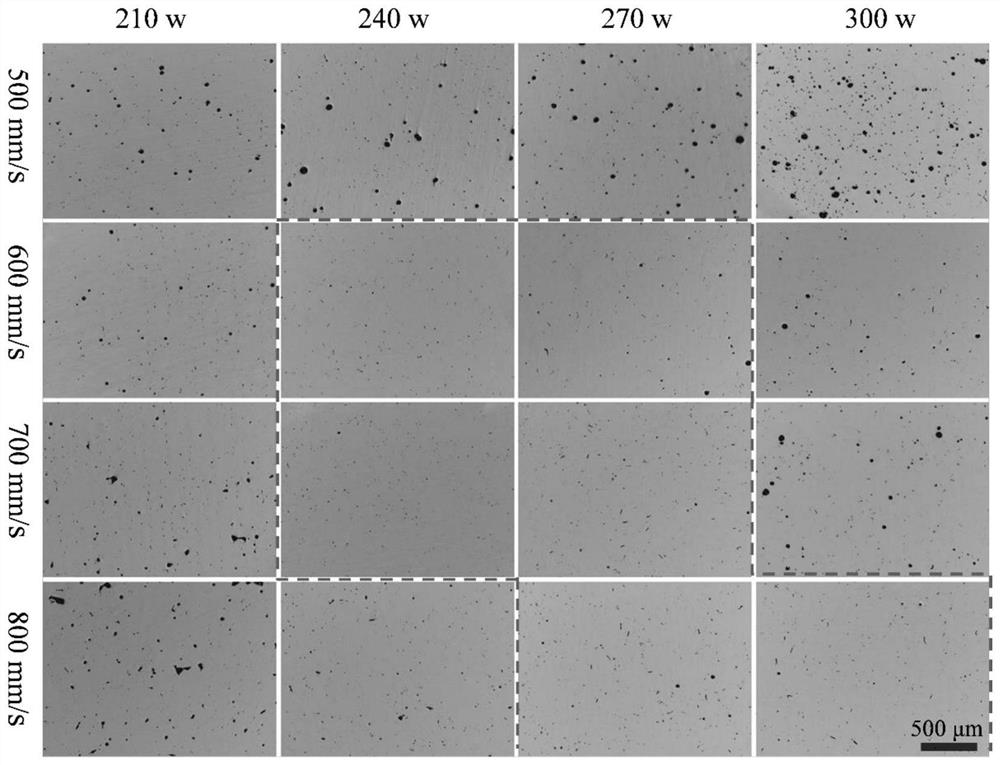

[0062] The traditional GH3536 and the modified GH3536M are subjected to laser selective melting and forming. The specific parameters are: substrate preheating temperature 100°C, laser scanning power 240w, laser scanning speed 600mm / s, powder coating thickness 0.04mm, scanning distance 0.1mm, progressive scanning 67° rotation between layers.

[0063] The GH3536 alloy and GH3536M alloy were formed by selective laser melting, and after electrochemical polishing, the microstructures were compared and analyzed, as follows: Figure 4 As shown in (a) and (b), the comparison found that the microcracks of the GH3536M alloy were almost eliminated.

[0064] For the modified GH3536M alloy formed by selective laser melting and the traditional brand GH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com