Light quantity nanometer energy-gathering vessel

An energy-gathering and nano-technology, applied in the field of utensils, can solve the problems of unfriendly human health, uneven surface structure, and inconvenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

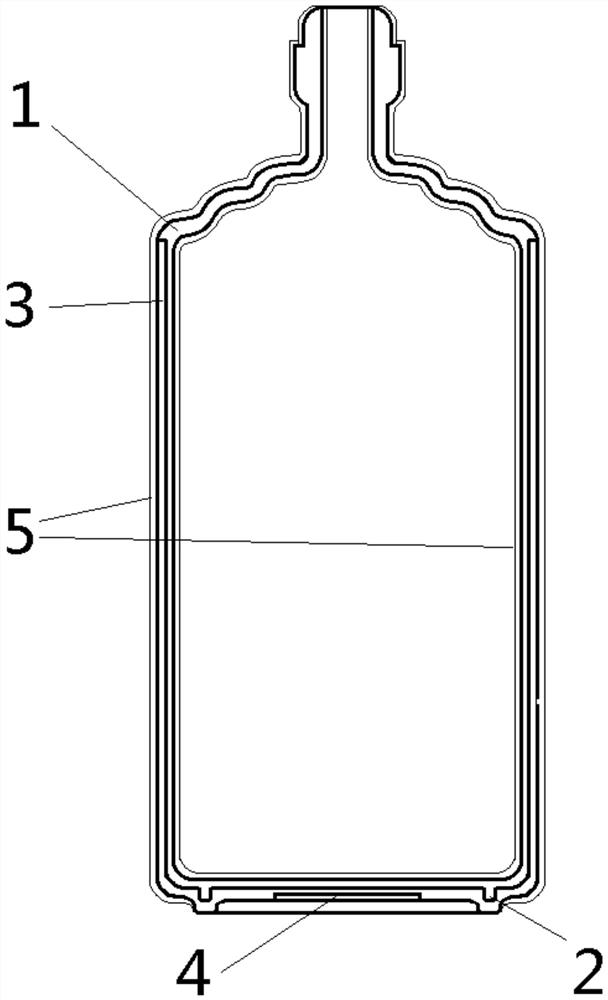

[0025] according to figure 1 As shown, the present invention provides a kind of light nano-energy gathering vessel, which includes: a sintered base layer 1, the sintered base layer 1 is a bottle structure, and the bottom is provided with a ring-shaped base 2; a nano-light energy gathering layer 3, the nano-light The energy-gathering layer 3 is covered on the outside of the sintered base layer 1, and the nano-light energy-gathering layer 3 is provided with a groove corresponding to the center of the annular base 2, and a terahertz energy-gathering chip 4 is embedded in the groove; An enamel layer 5 , the enamel layer 5 covers the outside of the nano-light energy gathering layer 3 .

[0026] Wherein, the nano-light energy gathering layer 3 is made of crater mineral powder, tourmaline nano-powder, mixed crystal ore powder and kaolin through nano-processing ultra-high temperature fusion; It is made by mixing stone powder and zircon powder; the terahertz energy-concentrating chip ...

Embodiment 2

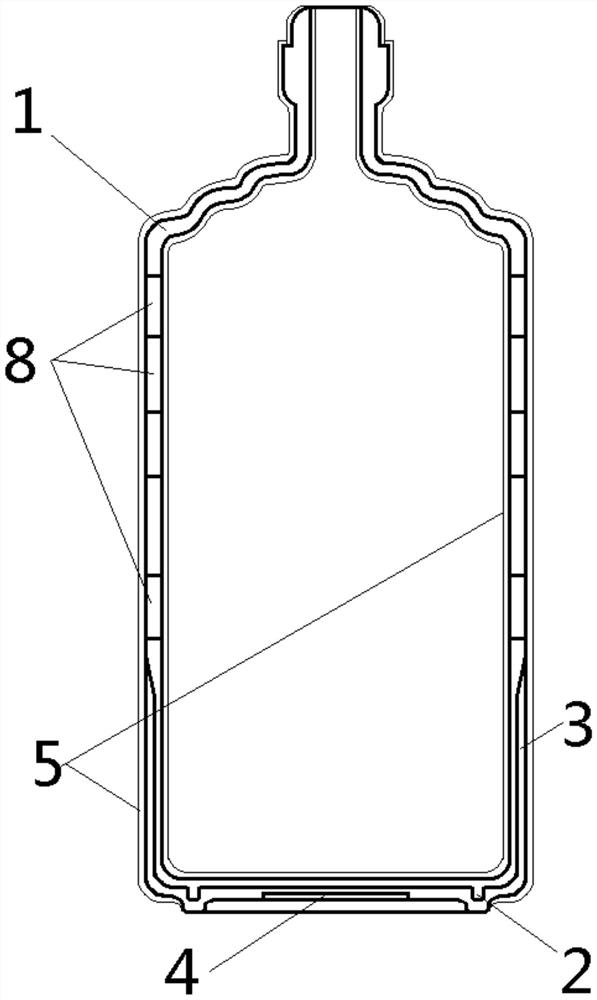

[0036] according to figure 2 As shown, the surface of the sintered base 1 is provided with a plurality of penetrating decorative windows 8; the nano-light energy gathering layer 3 covers the lower half of the outer wall of the sintered base 1; the enamel layer 5 covers the sintered The inner wall and the outer wall of the base layer 1 and the outer wall of the nano-light energy gathering layer 3 .

[0037] In the above settings, since the light transmittance of the sintered base layer 1 and the enamel layer 5 are different, when the light shines on the sintered vessel, its outer wall can show the shadow of the sintered base layer 1, forming a light and dark pattern pattern, which improves the art. value and appreciation.

Embodiment 3

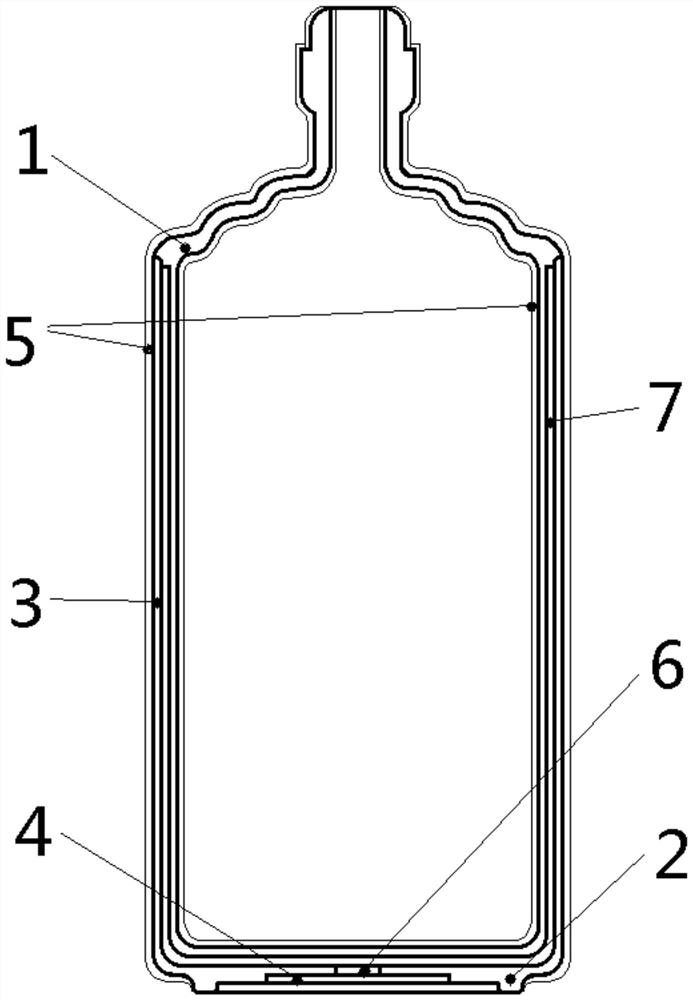

[0039] according to image 3 As shown, the inner wall of the nano-light energy gathering layer 3 is spaced apart from the outer wall of the sintered base layer 1 to form an accommodation space; at the same time, the annular base 2 is adjusted at the bottom of the nano-light energy gathering layer 3, and the nano-light energy gathering layer The groove at the bottom of 3 is provided with an injection hole 6 that communicates with the interior of the accommodation space; the accommodation space is filled with flexible adhesive glue 7 . The manufacturing process of the light quantity nano-energy concentrating vessel includes the following steps:

[0040] Step 1. Carry out primary sintering of the shaped base layer blank and the nano-light energy gathering layer 3 blank adapted to the base layer blank to form the sintered base layer 1 and the formed nano-light energy gathering layer 3 respectively;

[0041] Step 2: Assembling the sintered base layer 1 and the nano-light energy-ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com