Welding system of relay coil processing device

A technology for relay coils and processing devices, which is applied in tin feeding devices, auxiliary devices, welding equipment, etc., and can solve problems such as pins being easily broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

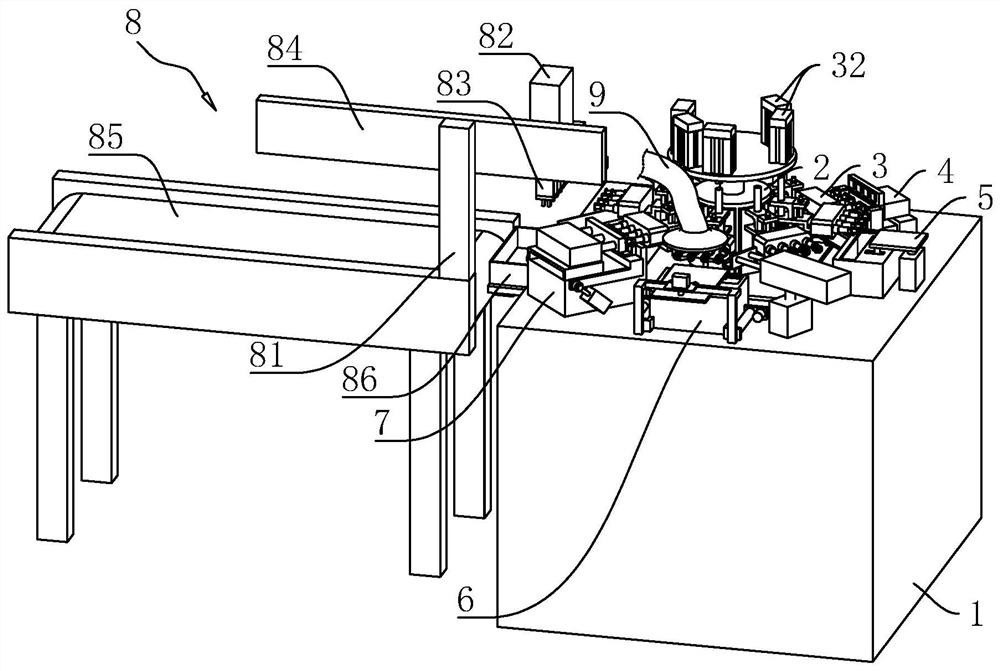

[0042] The following is attached Figure 1-8 The application is described in further detail.

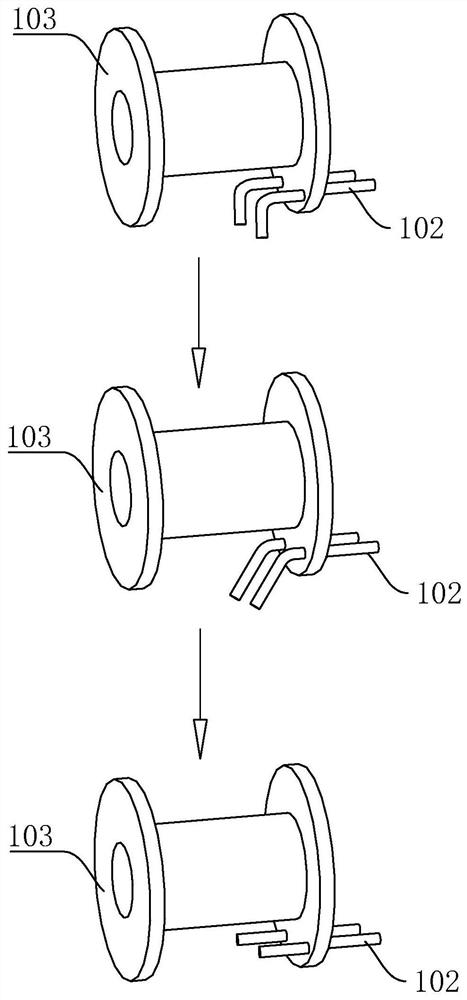

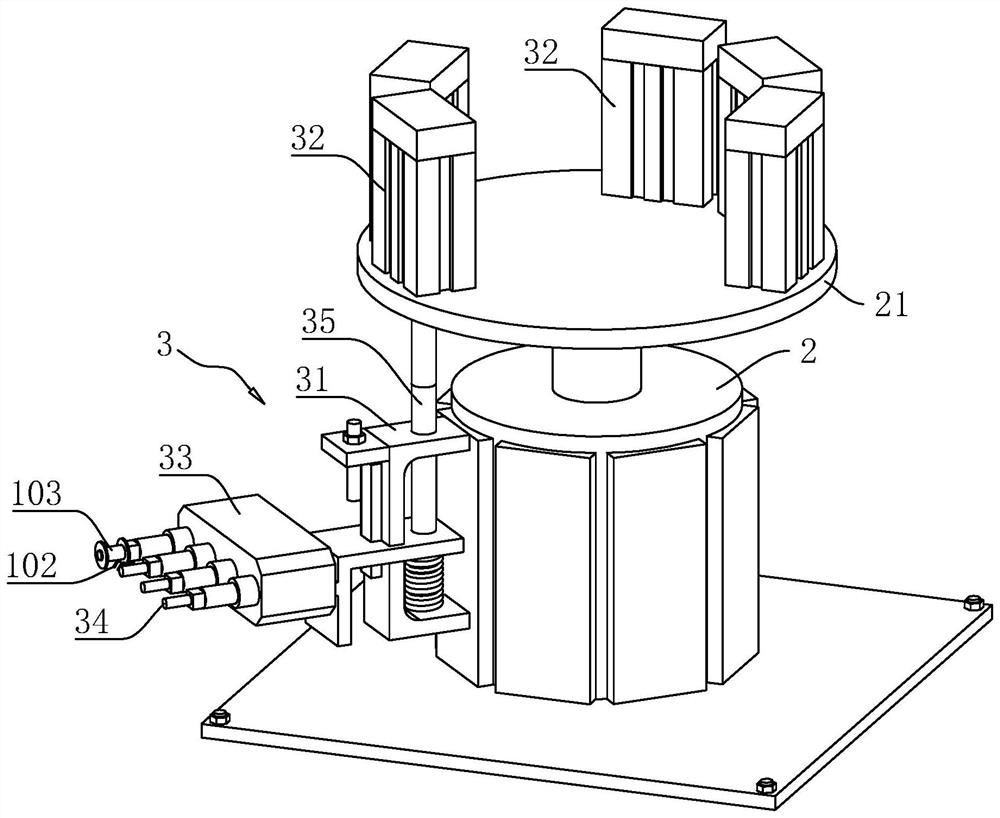

[0043] The embodiment of the present application discloses a welding system of a relay coil processing device. refer to figure 1 , the welding system of the relay coil processing device includes a frame 1, the center position of the upper surface of the frame 1 is vertically rotated and equipped with a rotating shaft 2, and the outer peripheral side of the rotating shaft 2 is provided with eight spacers for clamping the coil 103 along its circumferential direction. Clamping mechanism 3, frame 1 is provided with semi-bending mechanism 4, flux dipping mechanism 5, tinning mechanism 6, flattening mechanism 7 and blanking detection mechanism 8 on the outer periphery of rotating shaft 2 in sequence, and the five stations are synchronously The coils 103 on the five clamping mechanisms 3 are processed, and the coils 103 on the rest of the clamping mechanisms 3 can be in the state of waiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com