Bismuth vanadate@silver phosphate/graphene oxide composite photocatalyst as well as preparation method and application thereof

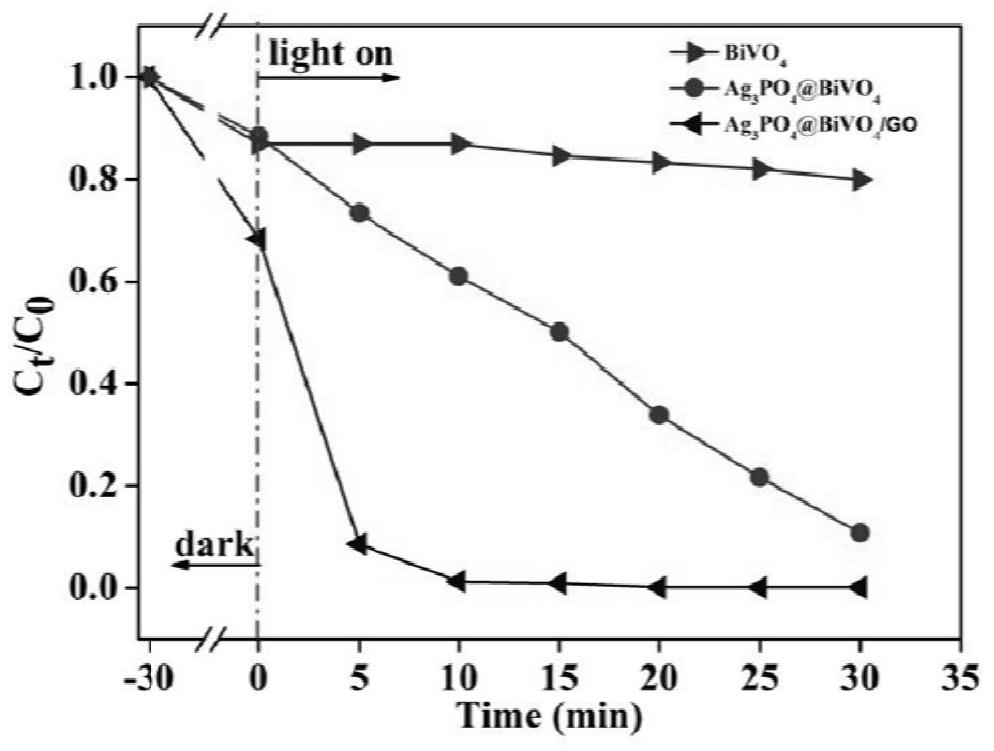

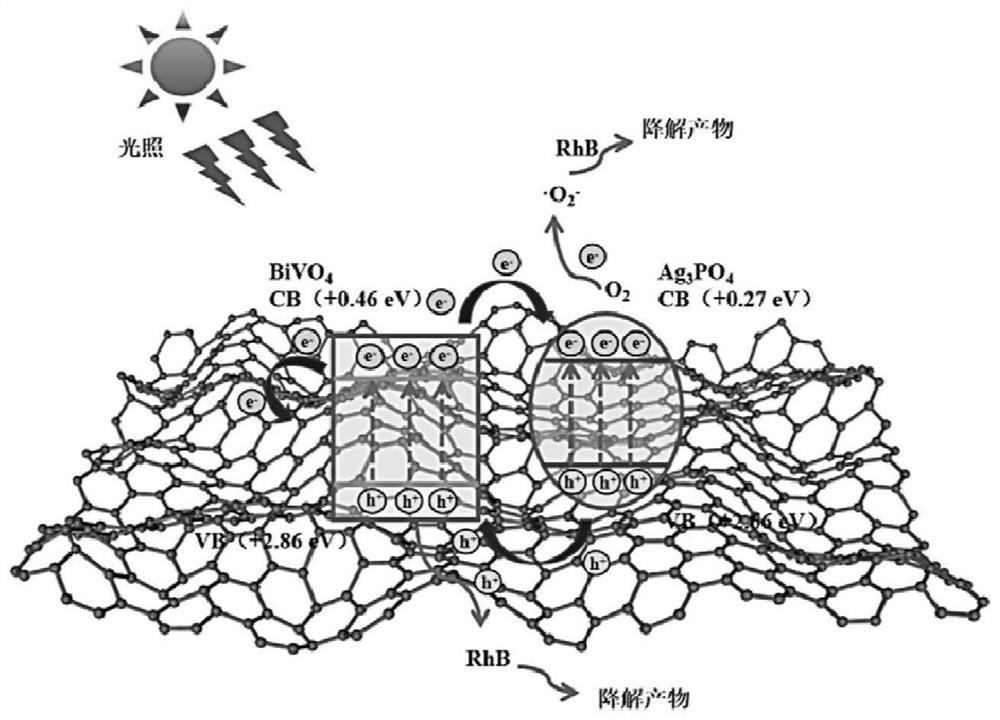

A graphene composite and photocatalyst technology, applied in the field of photocatalytic materials, can solve the problems of high cost and high charge recombination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

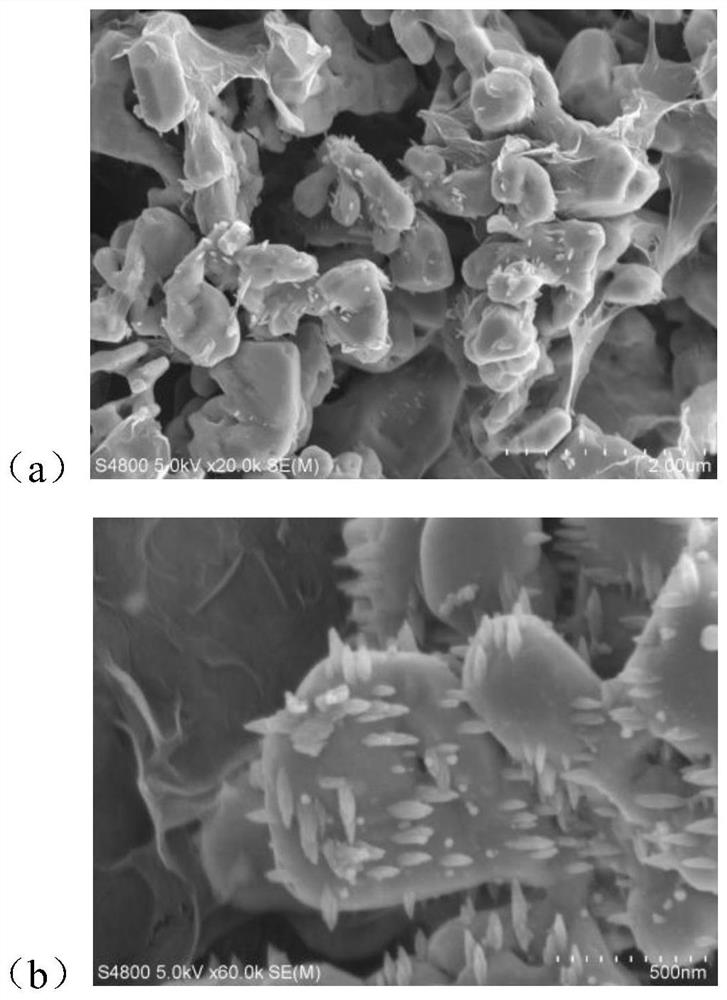

[0037] A preparation method of bismuth vanadate@silver phosphate / graphene oxide composite photocatalyst, the steps are as follows:

[0038] (1) bismuth vanadate (BiVO 4 ) with 10-20mL AgNO 3 Mix well in the water-ethanol mixed solvent (the volume ratio of ethanol to water is 1:5~10), and add 2.5mL H 3 PO 4 Mix the solution with 10-20mL ethanol, stir for 1-3 hours, collect the precipitate after aging for 1-3 hours; vacuum dry at 80°C for 12 hours to obtain bismuth vanadate@silver phosphate with a heterojunction structure;

[0039] (2) Graphene oxide (GO) was prepared by the improved Hummers method, and the prepared GO was dispersed in deionized water, and ultrasonically treated for 3 hours to obtain a GO suspension. Bismuth vanadate@silver phosphate and graphene oxide suspension were uniformly dispersed to obtain a reactant system, which was centrifuged, washed with deionized water and ethanol for 3 times, and freeze-dried for 12 hours to obtain bismuth vanadate@silver phosp...

Embodiment 1

[0049] 17g Bi(NO 3 ) 3 ·5H 2 O and 2NH 4 VO 3 respectively dissolved in 100mL, 1.5mol / L HNO 3 in solution. Under stirring conditions, the NH 4 VO 3 solution added Bi(NO 3 ) 3 ·5H 2 O solution, stirred for 60 min. The pH value of the mixed solution was adjusted to 1.5 with ammonia water, resulting in an orange precipitate. After aging for 2 hours, the orange precipitate was transferred to a hydrothermal reactor and reacted at 200°C for 24 hours. After the autoclave was naturally cooled to room temperature, the precipitate was collected, washed three times with deionized water, and dried under vacuum at 80°C for 12 hours to obtain BiVO 4 ; the BiVO 4 with 10mL AgNO 3 Mix evenly in a water-ethanol mixed solvent (volume ratio of ethanol to water is 1:8) (AgNO 3 with BiVO 4 The mass ratio is 0.5:1), add 2.5mL H to the above solution under stirring condition 3 PO 4 Mix the solution with 10mL ethanol, stir for 1h, collect the precipitate after aging for 2h; dry the ...

Embodiment 2

[0053] 15g Bi(NO 3 ) 3 ·5H 2 O and 3g NH 4 VO 3 respectively dissolved in 100mL, 1.5mol / L HNO 3 in solution. Under stirring conditions, the NH4 VO 3 solution added Bi(NO 3 ) 3 ·5H 2 O solution, stirred for 60 min. The pH of the mixed solution was adjusted to 2 with ammonia water, resulting in an orange precipitate. After aging for 1.5 h, the orange precipitate was transferred to a hydrothermal reaction kettle and reacted at 200°C for 24 h. After the autoclave was naturally cooled to room temperature, the precipitate was collected, washed three times with deionized water, and dried under vacuum at 80°C for 12 hours to obtain BiVO 4 ; the BiVO 4 with 10mL AgNO 3 Mix evenly in a water-ethanol mixed solvent (volume ratio of ethanol to water is 1:8) (AgNO 3 with BiVO 4 The mass ratio is 0.8:1), add 2.5mL H to the above solution under stirring condition 3 PO 4 Mix the solution with 10mL ethanol, stir for 1h, collect the precipitate after aging for 2h; dry the obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com