Method for treating alkaline residue through combination of chemical conditioning and vacuum preloading

A technology for chemical conditioning and alkali slag, applied in chemical instruments and methods, sludge treatment, improvement of process efficiency, etc., can solve the problem of reducing the vacuum preloading consolidation rate, bending the vertical drainage plate, and difficult to meet the dehydration of alkali slag. The need for reinforcement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

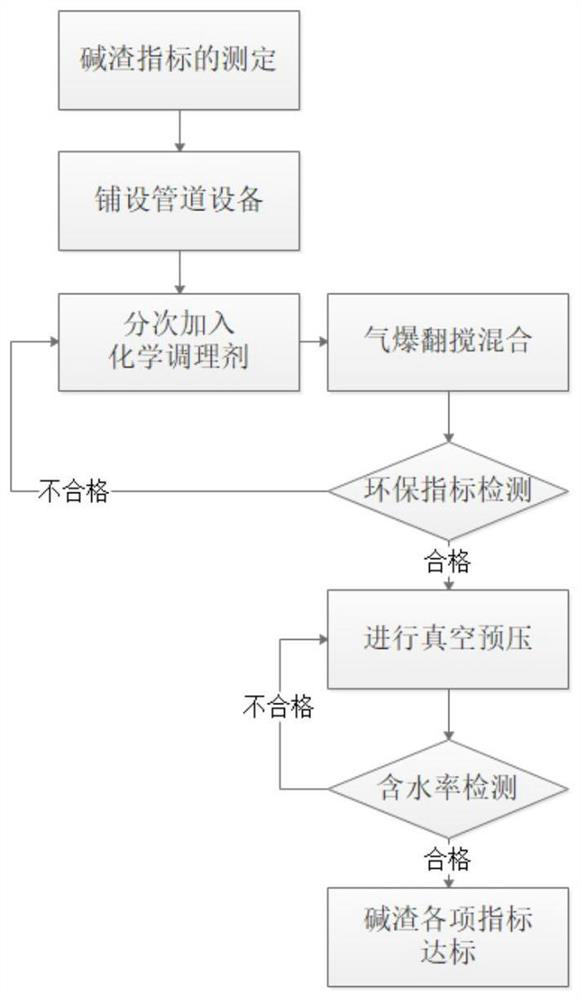

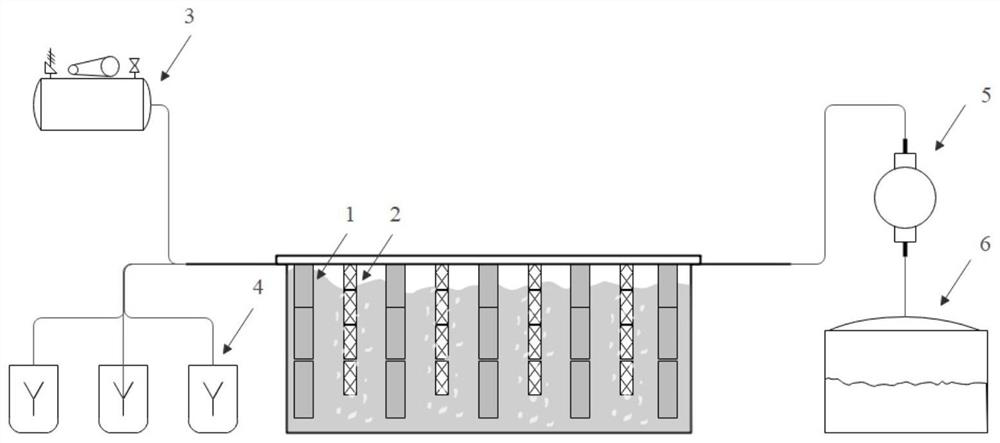

[0030] A method for chemical conditioning combined with vacuum preloading to treat alkali slag, the steps are as follows:

[0031] (1) Detect the pH of the alkali slag in the alkali slag pool to be 11.3, the moisture content is 72%, and the ammonia nitrogen value is 85mg / L;

[0032] (2) Add the coagulant, flocculant and acid reagent chemical conditioner to the feeding preparation bin 4 to prepare a solution according to a certain amount, wherein the coagulant is polyaluminum sulfate, and the flocculant is a mass ratio of 1:3 Polyacrylamide and hydroxymethylcellulose, the acid reagent is citric acid;

[0033] (3) After the prepared chemical conditioner is evenly stirred, it is sent to the alkali slag pool through the pipeline pump in turn, and the gas injection device 3 is opened, and the injected gas is continuously and fully gas-explosively stirred and bubbling, so that the chemical conditioner is added to the alkali slag In the process, the amount of coagulant, flocculant a...

Embodiment 2

[0037] (1) Detecting the pH of the alkali slag in the alkali slag pool is 10.9, the water content is 87%, and the ammonia nitrogen value is 65mg / L;

[0038] (2) Coagulants, flocculants and acid reagent chemical conditioners are added to the feeding preparation bin 4 according to a certain amount to prepare a solution, wherein the coagulant is polyaluminum sulfate, and the flocculants are phosphoric acid type amphoteric starch, acid Reagent is the hydrochloric acid of 30% mass concentration;

[0039] (3) After the prepared chemical conditioner is evenly stirred, it is sent to the alkali slag pool through the pipeline pump in turn, and the gas injection device 3 is opened, and the injected gas is continuously and fully gas-explosively stirred and bubbling, so that the chemical conditioner is added to the alkali slag In the process, until it can be fully mixed with the alkali slag, the amount of coagulant, flocculant and acid reagent added is 5%, 0.3% and 5% of the mass of the al...

Embodiment 3

[0043] (1) Detecting the pH of the alkali slag in the alkali slag pond is 12.2, and the moisture content is 81%, and the ammonia nitrogen value is 105mg / L;

[0044] (2) Add the coagulant, flocculant and acid reagent chemical conditioner to the feeding preparation bin 4 according to a certain amount to prepare a solution, wherein the coagulant is polyaluminum chloride and polyaluminum sulfate at a ratio of 1:1, flocculation The reagent is polyacrylamide, and the acid reagent is sulfuric acid of 98% mass concentration;

[0045] (3) After the prepared chemical conditioner is evenly stirred, it is sent to the alkali slag pool through the pipeline pump in turn, and the gas injection device 3 is opened, and the injected gas is continuously and fully gas-explosively stirred and bubbling, so that the chemical conditioner is added to the alkali slag In the process, until it can be fully mixed with the alkali slag, the amount of coagulant, flocculant and acid reagent added is 3%, 0.3% a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com