An aerial intelligent spraying construction robot

A kind of construction robot and intelligent technology, applied in the direction of construction, building structure, manipulator, etc., can solve the problems of battery replacement platform to increase operating costs, battery replacement process is complicated, etc., to improve spraying efficiency and spraying quality, improve efficiency and accuracy , the effect of meeting the battery life requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

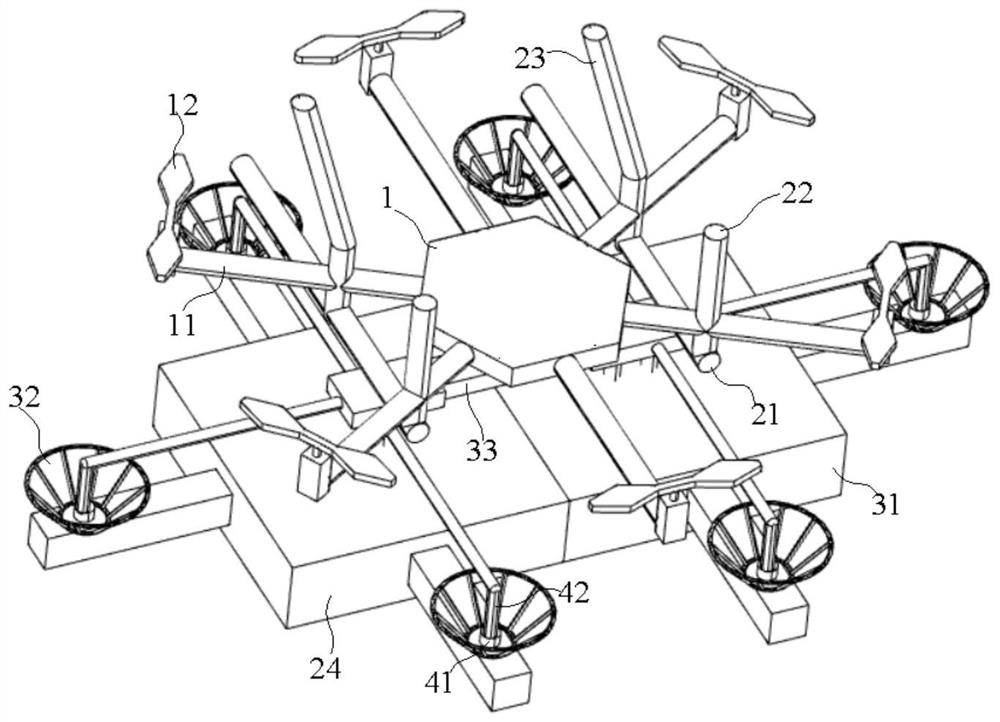

[0041] combine figure 1 , figure 2 and Figure 4 , a kind of aerial intelligent spraying construction robot of the present embodiment, comprises unmanned aerial vehicle main body 1, spraying device 2 and power unit 3, wherein is provided with at least three mechanical arms 11 that are annularly spaced apart along the unmanned aerial vehicle main body 1 periphery, The end of the mechanical arm 11 is provided with a rotor 12, and the spraying device 2 is installed on the drone body 1 for spraying architectural paint; the power unit 3 is connected to the bottom of the body for providing power for the drone, which includes The battery 31, the copper clad plate 33 and the brush 35, the copper clad plate 33 is installed on the drone body 1 and is electrically connected to the battery 31 through the brush 35, and the battery 31 and the copper clad plate 33 are detachably connected. In this embodiment, drones are combined with building spraying, and the automation of building wall ...

Embodiment 2

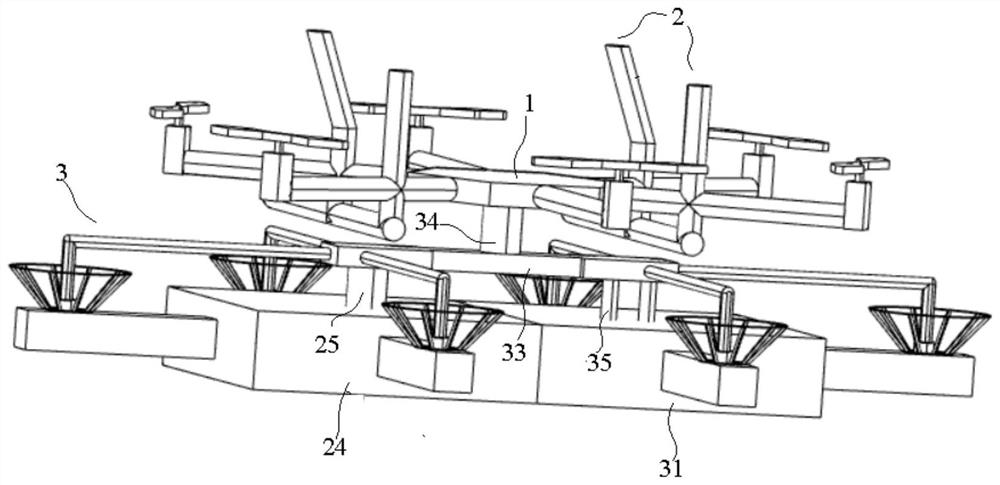

[0044] An aerial intelligent spraying construction robot of this embodiment has a structure basically the same as that of Embodiment 1, and the main difference is that in this embodiment, the top of the copper clad laminate 33 is fixedly connected to the drone body 1 through a fixed rod 34, and its surroundings Several second absorbing pieces 42 are installed, and several first absorbing pieces 41 matched with the second absorbing pieces 42 are installed around the battery 31 and the paint box 24 . The above-mentioned first adsorption part 41 and the second adsorption part 42 are magnetic adsorption devices, and the installation and replacement of the battery 31 can be realized through the cooperation of the first adsorption part 41 and the second adsorption part 42 .

[0045] It should be noted that there are currently research reports on spraying drones, but on the one hand, the endurance of existing drones is relatively poor; It is possible to reduce the weight of the UAV, ...

Embodiment 3

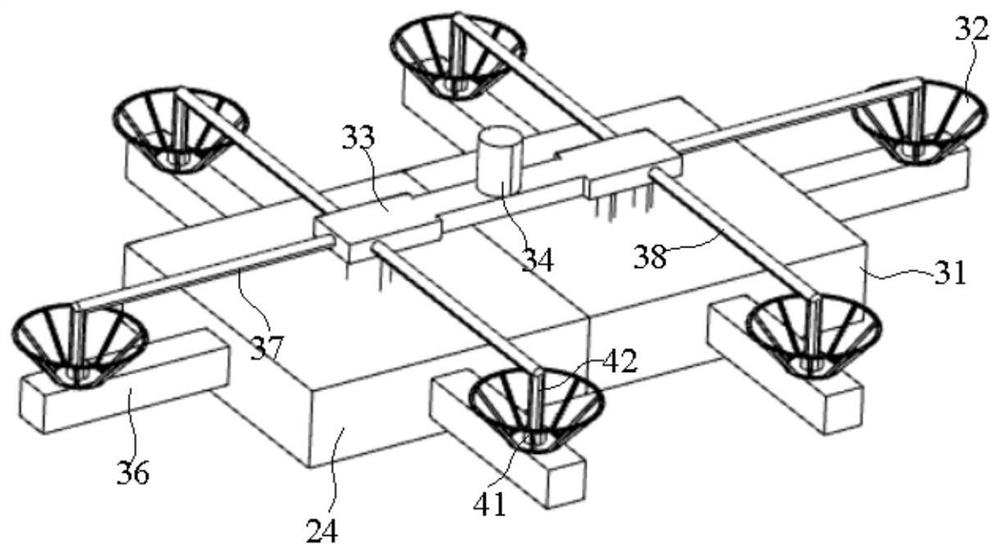

[0048] A kind of aerial intelligent spraying construction robot of this embodiment, its structure is basically the same as embodiment 2, and its difference mainly lies in: the outer periphery of the first adsorption part 41 in this embodiment is provided with the guide part 32 that is conical structure, as Figure 5 As shown, the guide 32 is composed of a first end 321, a second end 322 parallel to each other, and a plurality of spaced apart spokes 323 connecting the first end 321 and the second end 322 (the first end 321 is fixedly installed on the mounting plate 36), the first adsorption member 41 is located in the inner hole of the first end portion 321, and the inner diameter of the first end portion 321 is smaller than the inner diameter of the second end portion 322. The connection between the battery and the paint box and the drone can be guided through the setting of the guide, so that the accuracy of the alignment connection can be ensured, which is conducive to improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com