Antibacterial spinning mixture as well as preparation method and application thereof

A mixture and spinning technology, which is applied in the manufacture of rayon, textiles and paper, and conjugated synthetic polymer artificial filaments. It can solve the problems of high manufacturing cost of antibacterial masterbatch, complicated preparation method, environmental protection burden, etc., and achieve Good slow-release effect, environmental friendliness, strong water resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

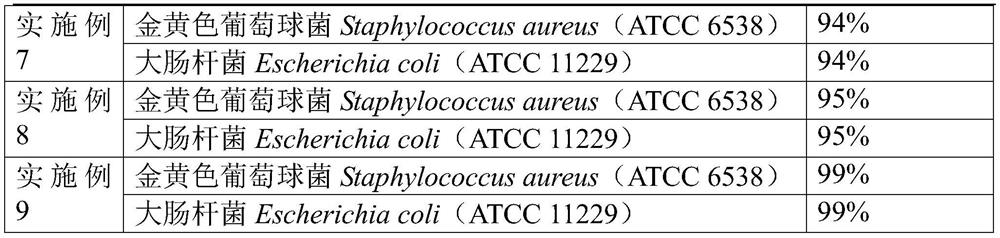

Examples

Embodiment 1

[0035] A kind of antibacterial spinning mixture of the present embodiment, its preparation method comprises the following steps:

[0036] (1) Mix 4,5-dichloro-N-octyl-4-isothiazolin-3-one (nanoscale) with acetyl tri-n-butyl citrate in a mass ratio of 1:2, and place In the ultrasonic dispersion equipment, fully mix for 10-20 minutes to obtain the compound antibacterial agent, and use it for later use (note: the compound antibacterial agent should not be left for a long time, and should be used within 8 hours);

[0037] (2) Mix the composite antibacterial agent prepared in step (1) with the carrier resin slice (this embodiment is a polyester slice) in a mass ratio of 1:99, and place it in a 200L high-speed mixer, stir and mix to obtain this embodiment antibacterial spinning mixture.

Embodiment 2

[0039] A kind of antibacterial spinning mixture of the present embodiment, its preparation method comprises the following steps:

[0040] (1) Mix 4,5-dichloro-N-octyl-4-isothiazolin-3-one (nanoscale) with acetyl tri-n-butyl citrate in a mass ratio of 1:3, and place In the ultrasonic dispersion equipment, fully mix for 10-20 minutes to obtain the compound antibacterial agent, and use it for later use (note: the compound antibacterial agent should not be left for a long time, and should be used within 8 hours);

[0041] (2) The composite antibacterial agent prepared by step (1) is mixed with the carrier resin slice (the present embodiment is a polyester slice) in a mass ratio of 2:98, and placed in a 200L high-speed mixer, stirring and mixing;

[0042] (3) The mixture obtained in step (2) is melt-blended and sliced to obtain the antibacterial spinning mixture of the present embodiment.

Embodiment 3

[0044] A kind of antibacterial spinning mixture of the present embodiment, its preparation method comprises the following steps:

[0045](1) Mix 4,5-dichloro-N-octyl-4-isothiazolin-3-one (nanoscale) with acetyl tri-n-butyl citrate in a mass ratio of 1:1, and place In the ultrasonic dispersion equipment, fully mix for 10-20 minutes to obtain the compound antibacterial agent, and use it for later use (note: the compound antibacterial agent should not be left for a long time, and should be used within 8 hours);

[0046] (2) The composite antibacterial agent prepared by step (1) is mixed with the carrier resin slice (the present embodiment is a polyester slice) in a mass ratio of 0.1:99.9, and placed in a 200L high-speed mixer, stirring and mixing;

[0047] (3) The mixture obtained in step (2) is melt-blended and sliced to obtain the antibacterial spinning mixture of the present embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com