Feeding machine and feeding method for rare earth electrolysis

A feeding machine and rare earth technology, which is applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of inability to ensure regular feeding and uneven feeding, and achieve the effects of reducing manpower, avoiding material backflow, and uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

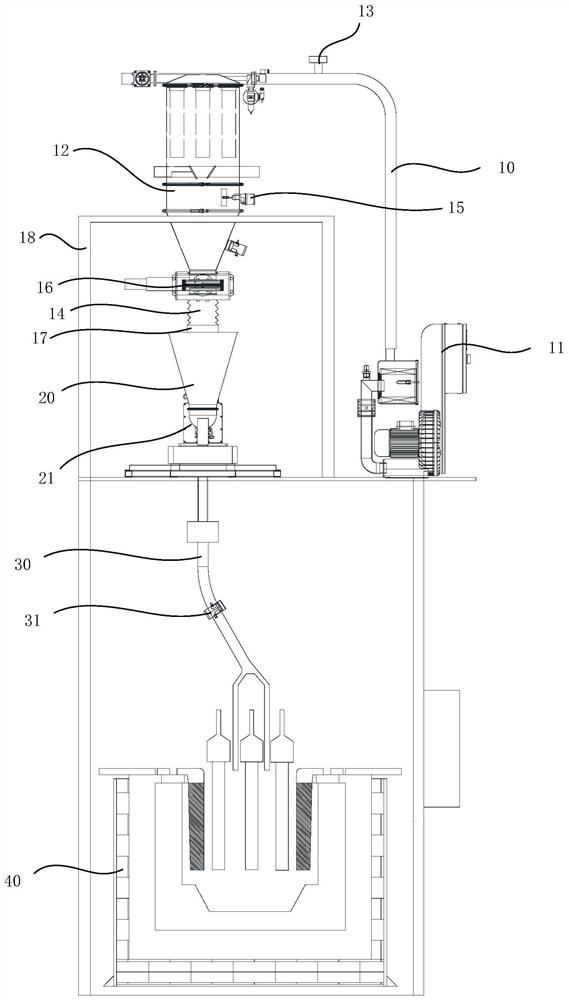

[0041] like figure 1 As shown, the feeder for rare earth electrolysis provided by the present invention includes sequentially connected: a vacuum feeding system, a weighing feeding system and a feeding system.

[0042] The vacuum feeding system includes a feeding pipe 10, an air pump 11, and a raw material bin 12 that are airtightly connected. One end of the feeding pipe 10 is connected to the raw material bin 12, and the other end is connected to the air pump 11. The feeding pipe 10 is also provided with a one-way valve 13. The raw material The bin 12 is externally connected to the feeding pipe through the feeding pipe interface 15, and the air pump 11 pumps air through the feeding pipe 10, so that the material is sucked into the raw material bin 12 through the feeding pipe. A pneumatic butterfly valve 16, a flexible connector 14 and a first weighing device 17 are sequentially arranged between the vacuum feeding system and the weighing feeding system, and the first weighing d...

Embodiment 2

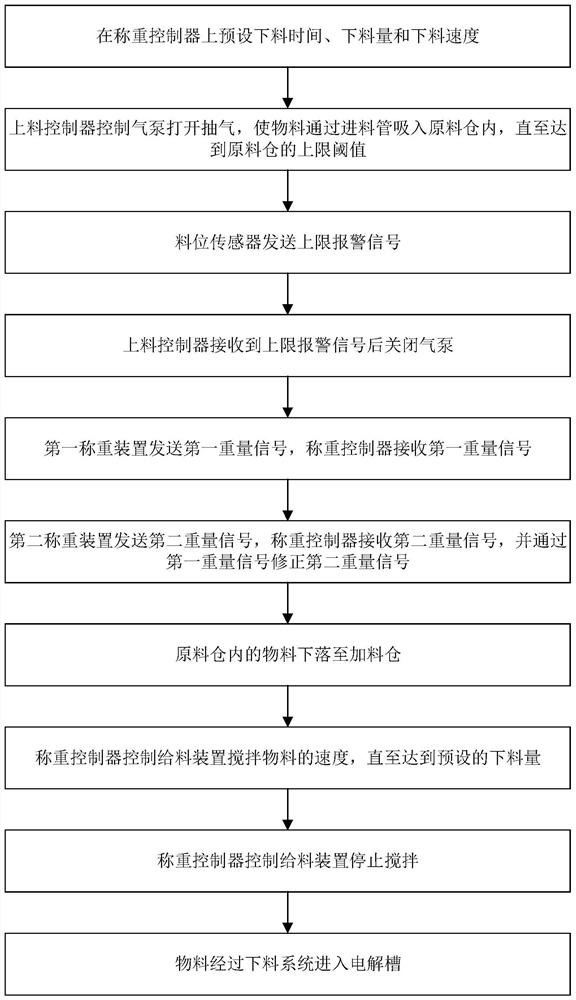

[0055] The feeding method of rare earth electrolysis provided in this embodiment includes the feeder of Embodiment 1, and also includes:

[0056] Preset the feeding time, feeding amount and feeding speed on the weighing controller;

[0057] The feeding controller controls the air pump 11 to turn on the air pumping, so that the material is sucked into the raw material bin 12 through the feeding pipe until the upper threshold of the raw material bin 12 is reached;

[0058] The material level sensor sends an upper limit alarm signal;

[0059] The feeding controller closes the air pump 11 after receiving the upper limit alarm signal;

[0060] The first weighing device 17 sends the first weight signal, and the weighing controller receives the first weight signal;

[0061] The second weighing device 21 sends a second weight signal, and the weighing controller receives the second weight signal, and corrects the second weight signal through the first weight signal;

[0062] The mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com