Manufacturing and machining equipment for one-way valve of air compressor and machining method

An air compressor and processing equipment technology, applied in metal processing equipment, manufacturing tools, thread trimmers, etc., can solve the problems of wasting working time, low processing efficiency, and inability to perform processing, saving tapping processing time, improving Processing efficiency, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

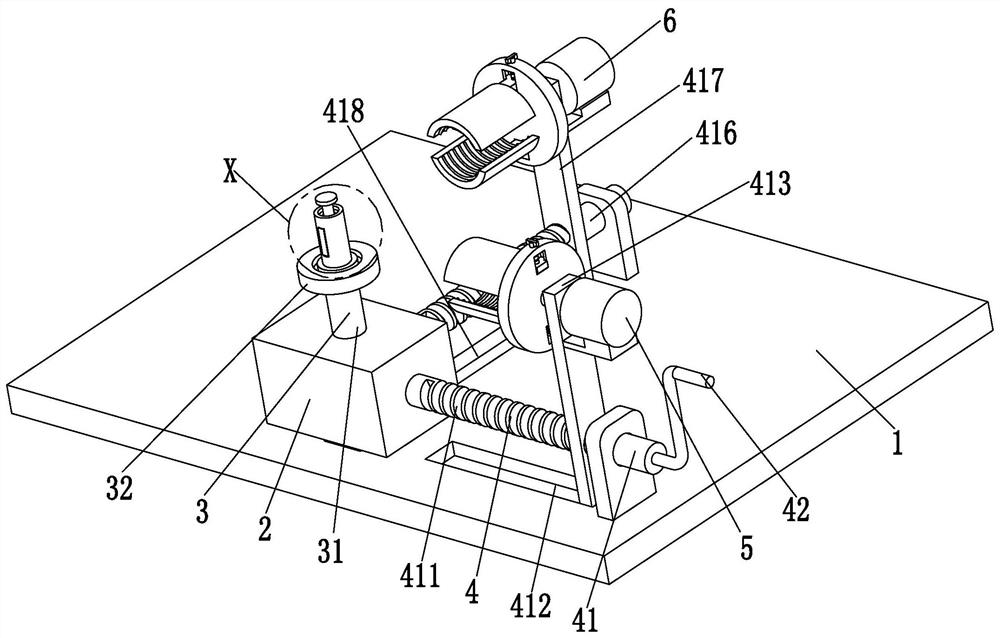

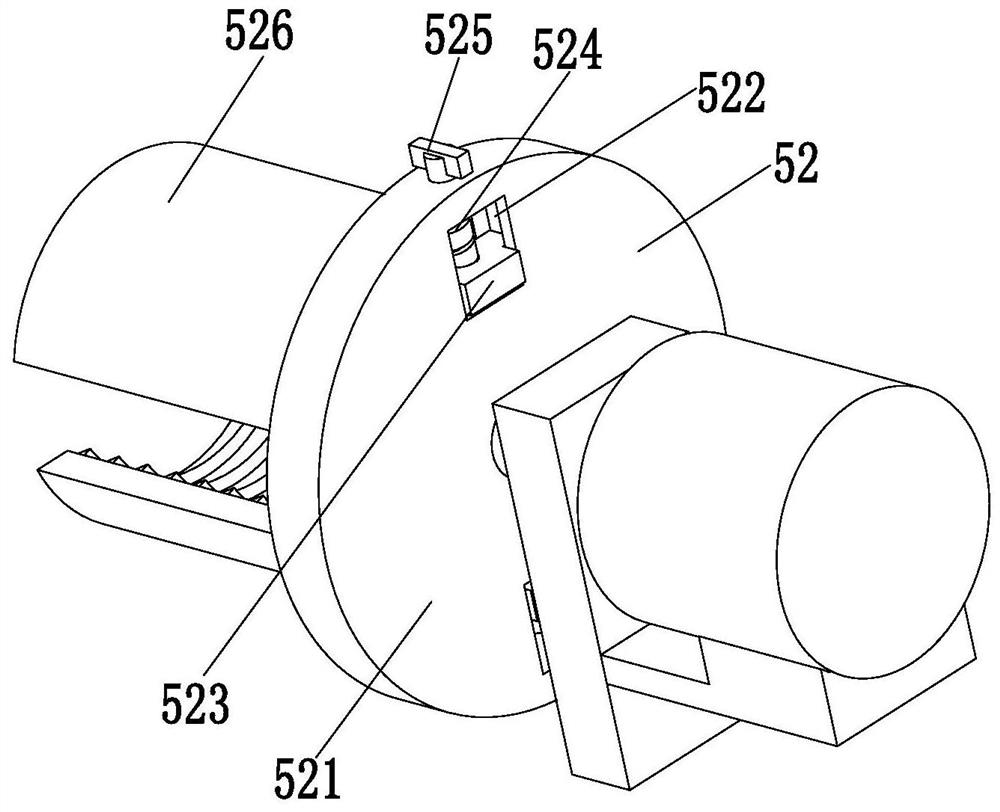

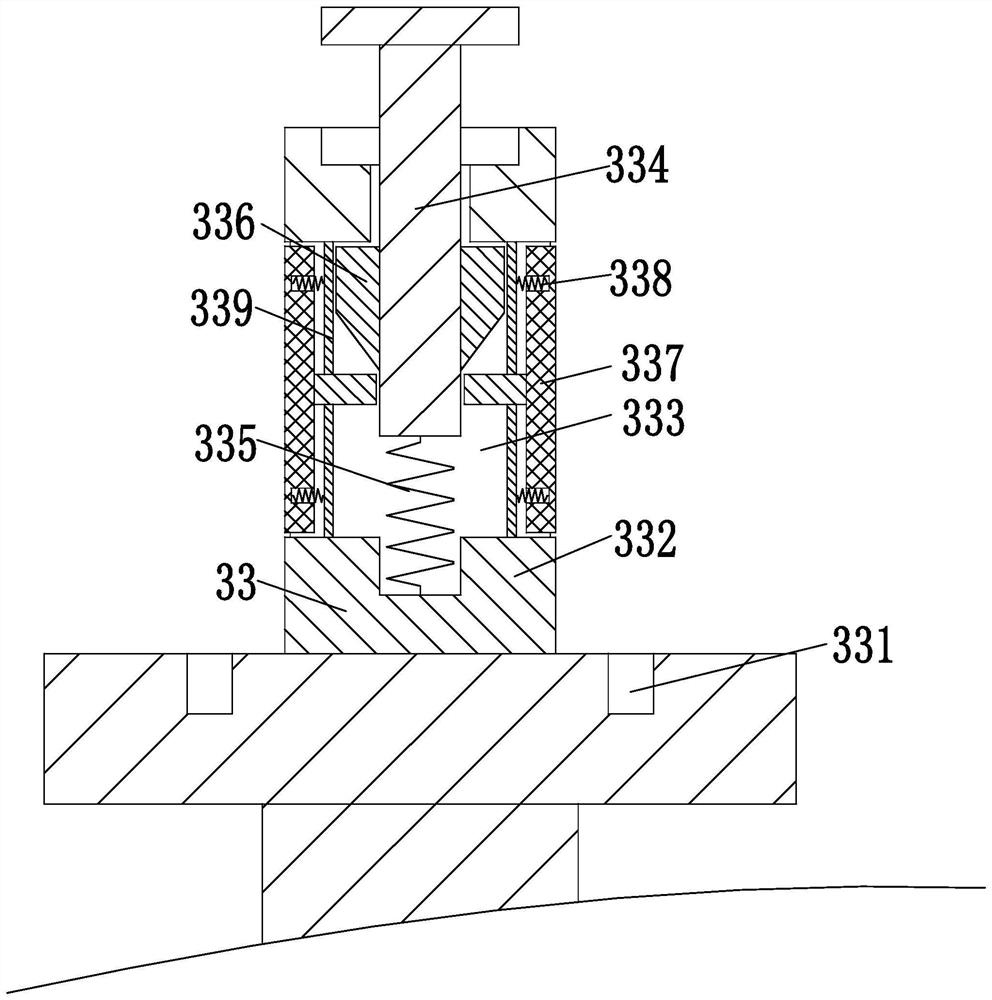

[0034] Such as Figure 1 to Figure 7 As shown, an air compressor check valve manufacturing and processing equipment includes a fixed base 1, an installation box 2, a locking device 3, a synchronous driving device 4, a No. 1 tapping device 5 and a No. 2 tapping device 6. The left side of the middle part of the upper end of the fixed base 1 is fixed with an installation box 2, the upper end of the installation box 2 is connected with a locking device 3, the installation box 2 is provided with a synchronous drive device 4, and the front side of the synchronous drive device 4 is provided with a No. 1 tapping Device 5, No. 2 tapping device 6 is arranged on the right side of synchronous driving device 4, and No. 1 tapping device 5 and No. 2 tapping device...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap