Flexible circuit board chip mounter

A technology for flexible circuit boards and placement machines, which is used in mechanical equipment, printed circuits, printed circuit manufacturing, etc., can solve problems such as low work efficiency and defects, and achieve the effect of improving work efficiency, speed, and enhancing fixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. DETAILED DESCRIPTION OF THE INVENTION The present invention is not intended to limit the invention. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

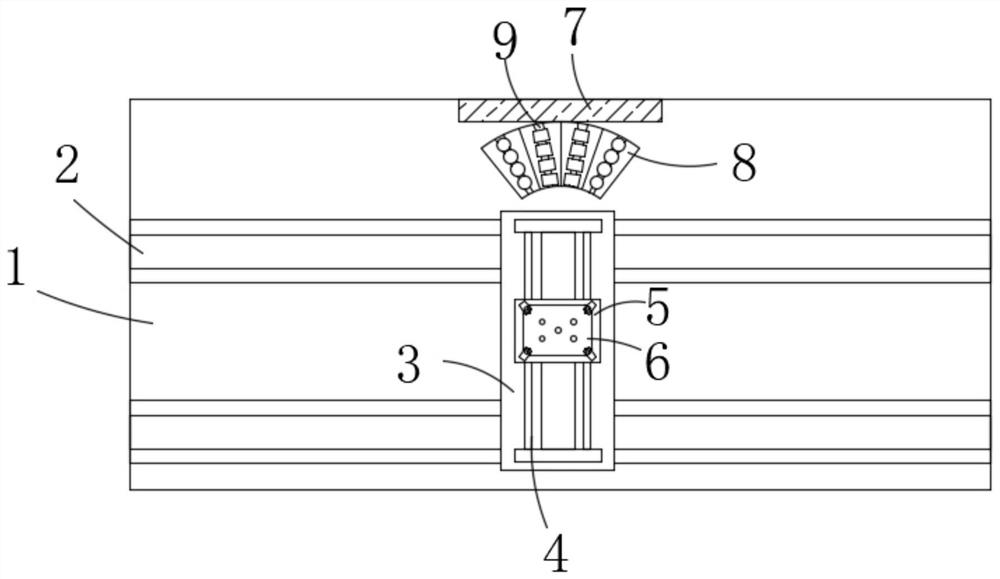

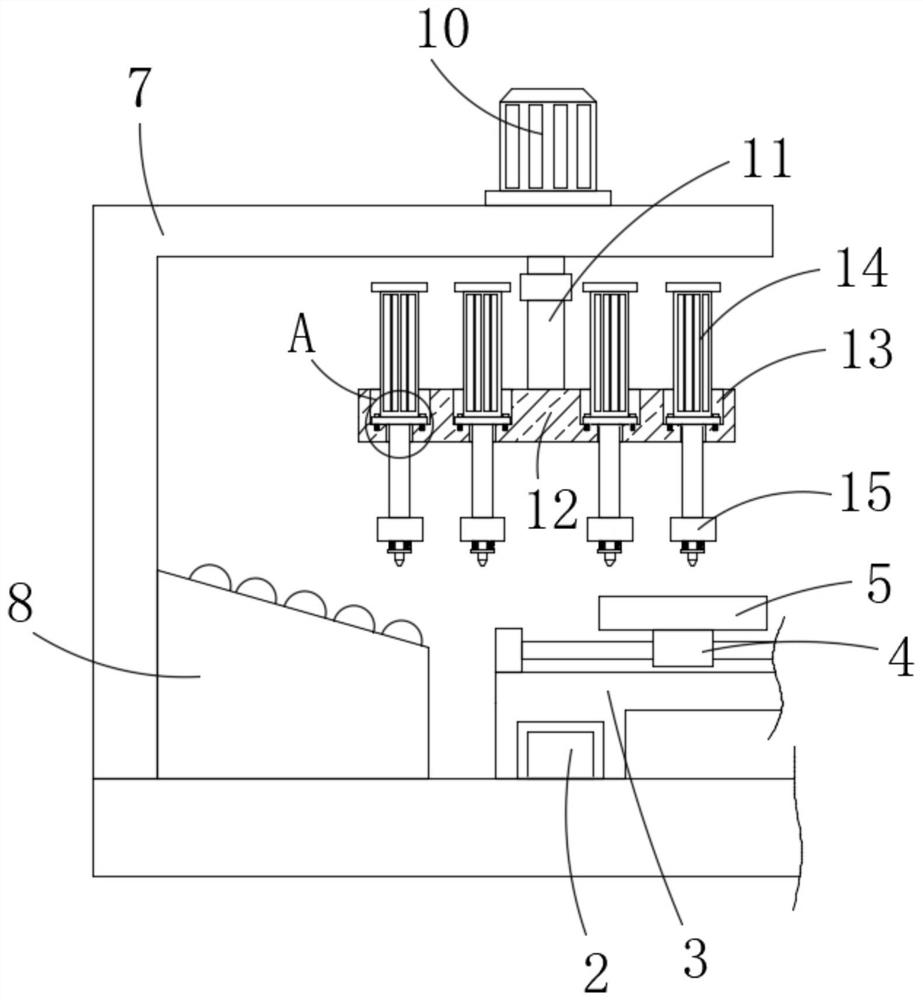

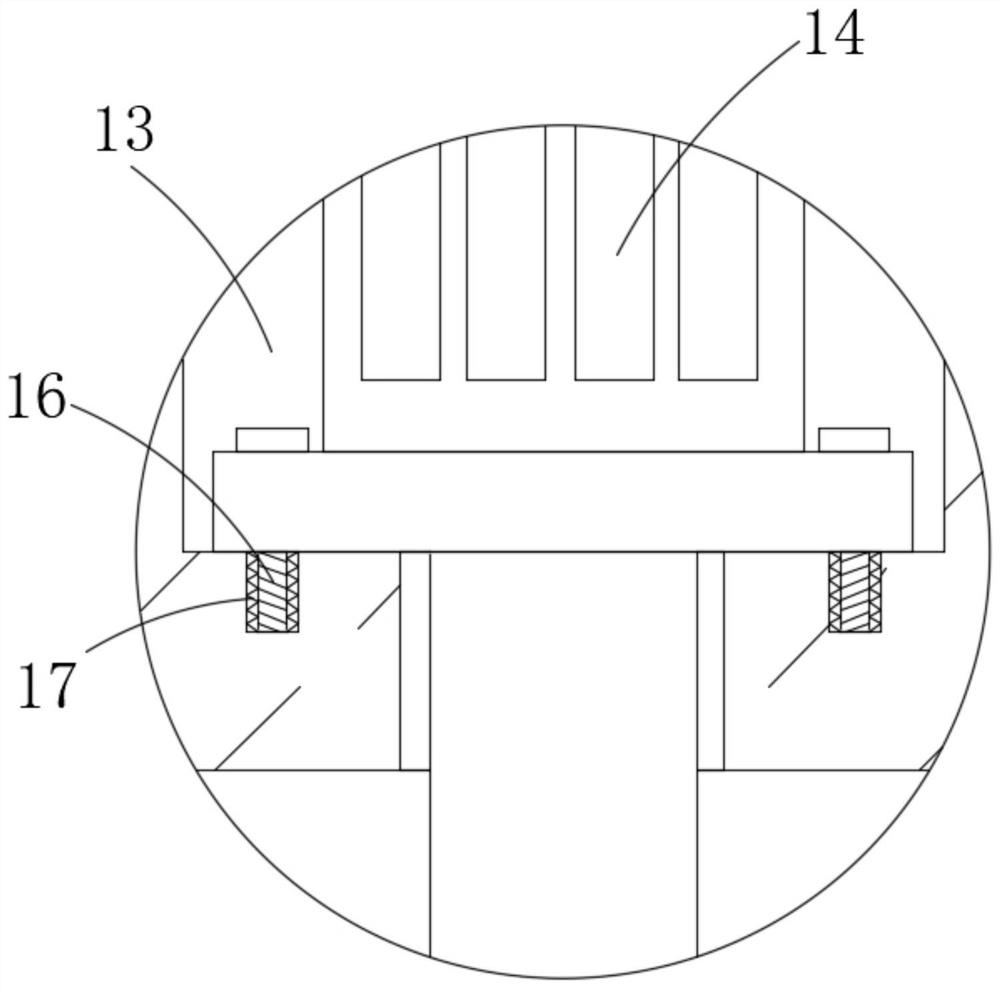

[0029] The present invention provides Figure 1-8 A flexible circuit board aircraft, including a table 1, a table 1, and a slide rail 2 is fixed, and two sets of rail 2 are provided, and the sliding rail 2 is slid. 3, the slide 3 Set to a U-shaped slide, the end of the slide 3 is opened with two sets of chutes, and the slider 3 is located inside the chute, and the motor slide 4 is fixedly mounted on the slide 3, the sliding se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com