Small plug-in connector with wire locking function

A plug-in connector technology, applied in the direction of connection, conductive connection, clamping/spring connection, etc., can solve the problems of increasing connector size, insufficient clamping force, poor contact, etc., to improve stability and improve clamping Tightening force, size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

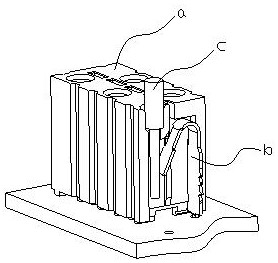

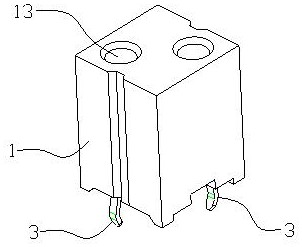

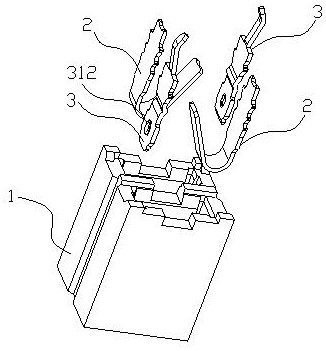

[0032] see Figure 2-8 As shown, the embodiment of the present invention discloses a small plug-in connector with a wire locking function, which includes a plastic housing 1 and at least one locking mechanism disposed in the plastic housing 1, and the locking mechanism includes oppositely arranged shrapnel terminals 2 and the contact conductive terminal 3, the spring terminal 2 and the contact conductive terminal 3 are elastically deformed to hold the electric wire 4 inserted between them.

[0033] Wherein, the shrapnel terminal 2 includes an insertion arm 21, a bending fillet 22 and an elastic arm 23, one end of the insertion arm 21 is bent to form a bending fillet 22, and the other end of the bending fillet 22 is connected to the elastic arm 23, elastically When the arm 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com