Clamp for typified form in construction and use method thereof

A technology for shaping formwork and building construction, which is applied in construction, building structure, building material processing, etc. It can solve the problems of complex structure of formwork fixing fixtures, high maintenance costs, low turnover efficiency, etc., and achieve light weight and reduce construction costs. , the effect of improving the turnover rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

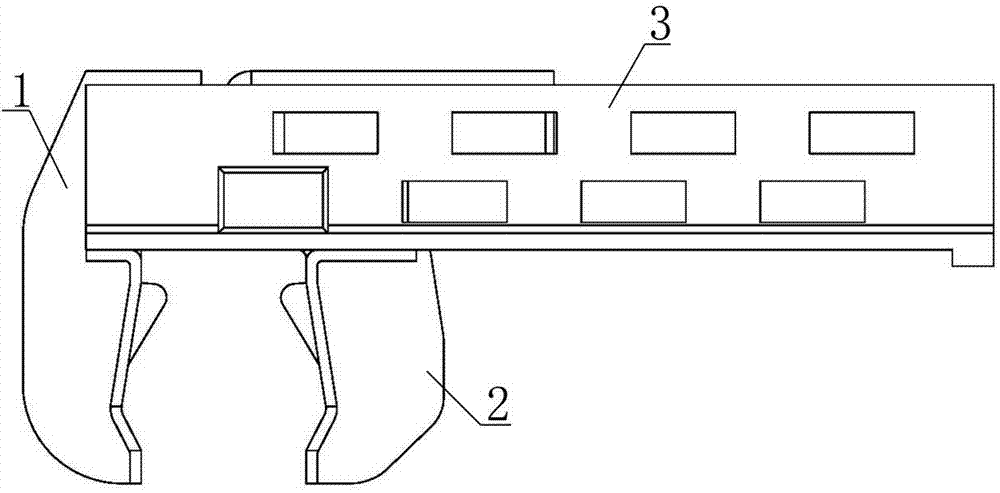

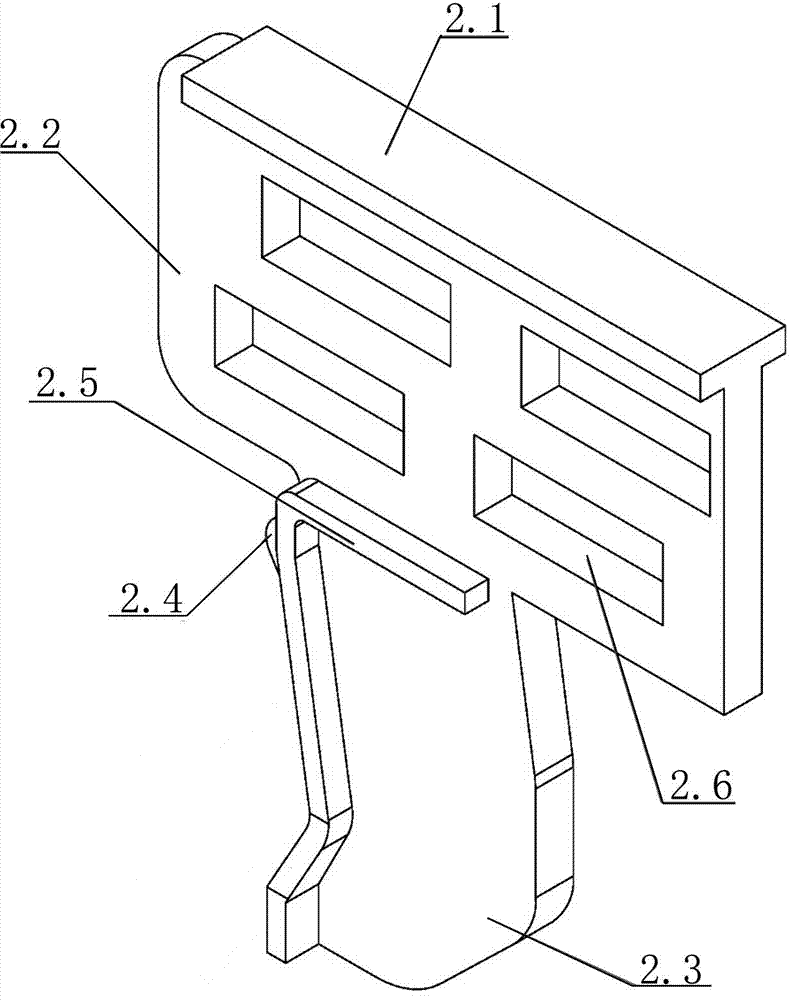

[0038] Examples see figure 1 with Image 6 As shown, a fixture for building construction stereotyped formwork includes a fixture main body 3 and a limit pin 4, and also includes a fixed claw 1 and a movable claw 2 that are independently arranged. The fixed claw 1 and the movable claw 2 are arranged oppositely, and the two are opposite The shape of the surface is adapted to the shape of the side surface of the clamped template frame 6. There is a long chute in the middle of the clamp body 3. The fixed claw 1 and the movable claw 2 are inserted into the chute of the clamp body 3 in sequence. The top surface of the fixed claw 1 is flush with the top surface of the fixture body 3 and is fixedly connected with the fixture body 3; the movable claw 2 can move in the chute of the fixture body 3, and the movable claw 2 passes through the limit pin after moving to a suitable position 4 is wedged tightly with the fixture main body 3.

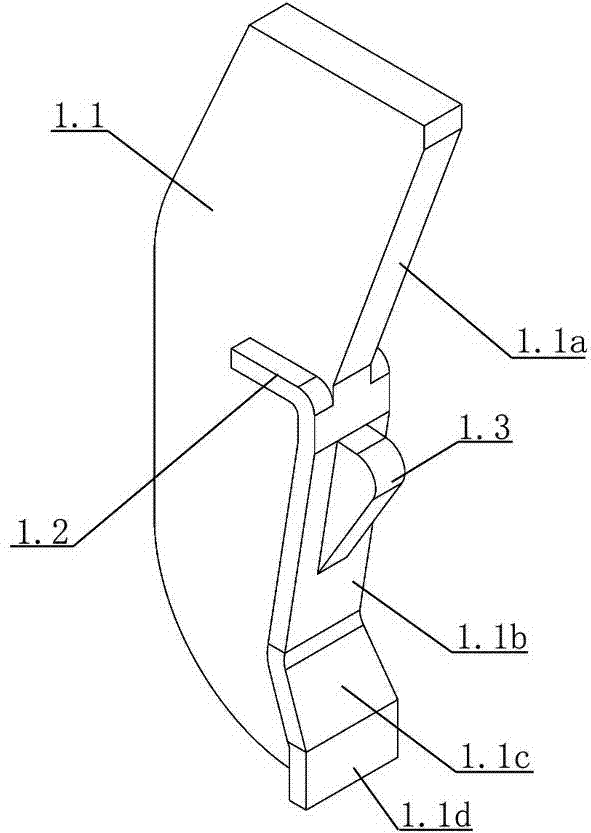

[0039] The fixed claw 1 see figure 2 , consistin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com