Coal-fired boiler with reduced nitric oxide spraying device

A technology of nitrogen oxides and injection devices, which is applied in the field of coal-fired boilers and coal-fired boilers with reduction nitrogen oxides injection devices. To achieve the effect of rapid and stable enhanced ignition, increased oxygen content, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

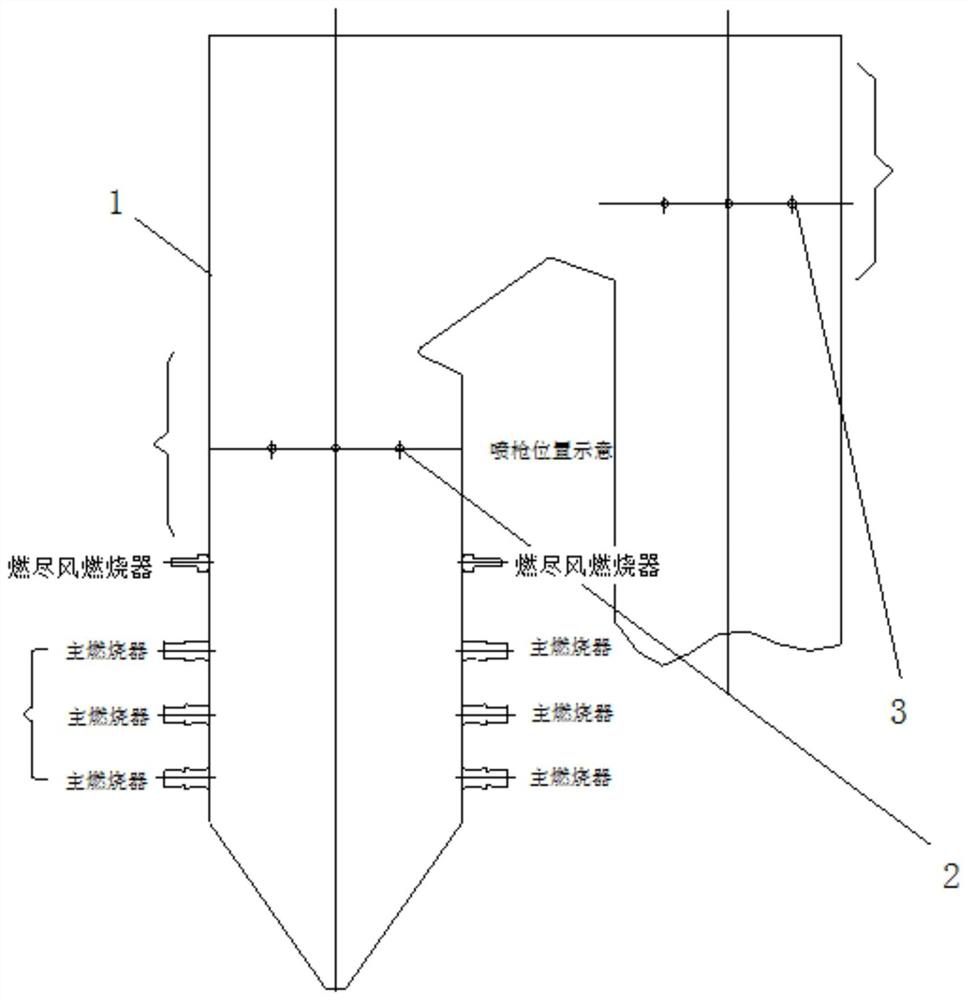

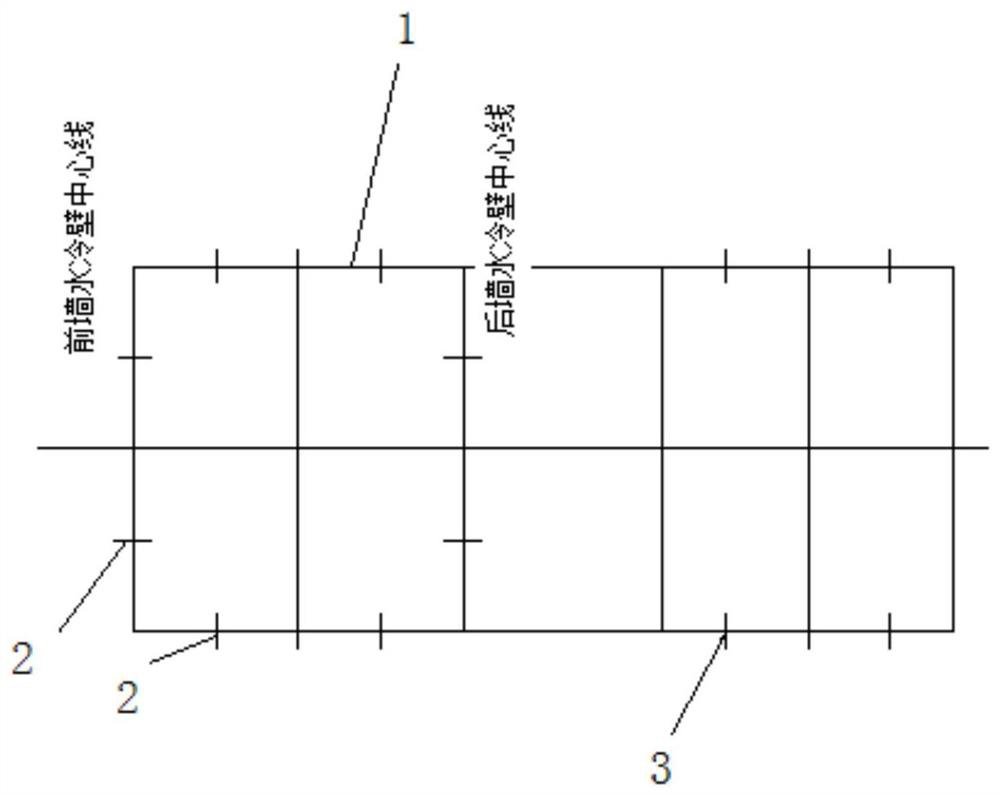

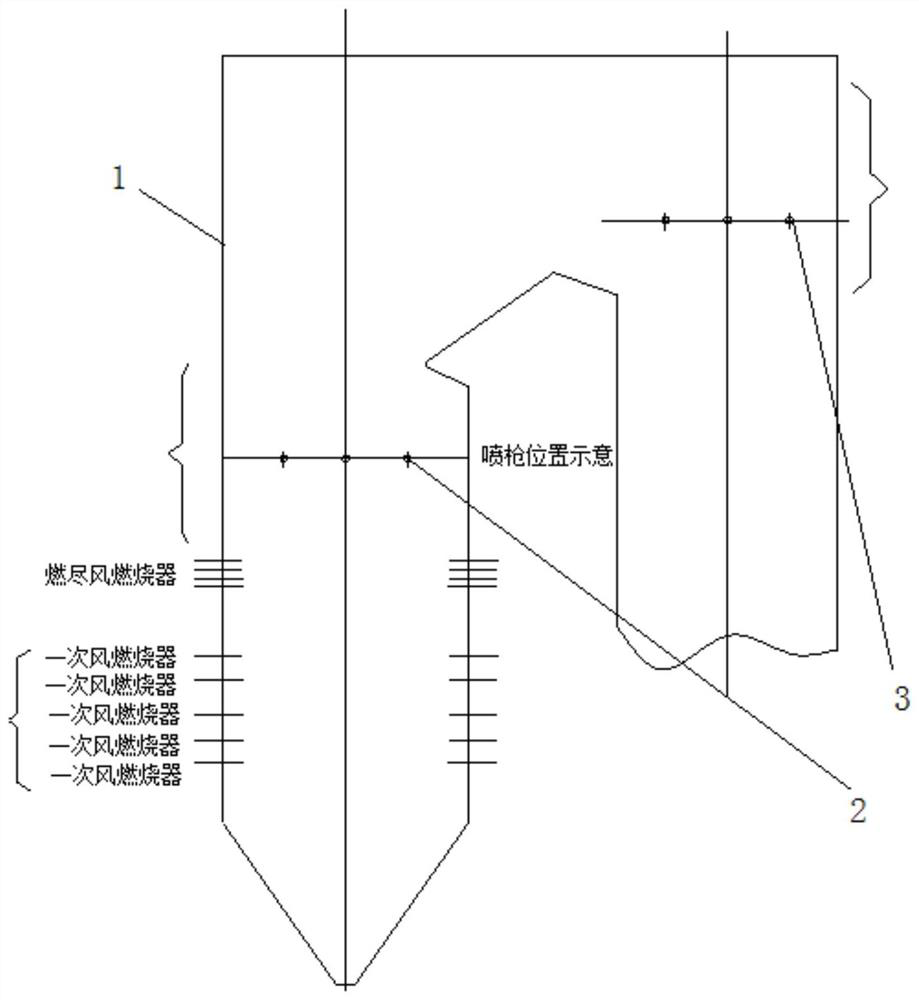

[0021] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, a kind of coal-fired boiler with reduction nitrogen oxide injection device described in this embodiment, it includes furnace body 1; This embodiment also includes a plurality of first forced reduction nitrogen oxide spray guns 2, a plurality of The first forced reduction nitrogen oxide spray gun 2 is installed between the burner of the exhaust air in the furnace body 1 and the refraction angle of the furnace.

specific Embodiment approach 2

[0022] Specific implementation mode two: combination Figure 1 to Figure 5 To illustrate this embodiment, a plurality of first forced reduction nitrogen oxide spray guns 2 of a coal-fired boiler with an injection device for reducing nitrogen oxides in this embodiment refers to at least two first forced reduction nitrogen oxide spray guns 2 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination Figure 1 to Figure 5 Describe this embodiment, a coal-fired boiler with a reduced nitrogen oxide injection device described in this embodiment also includes a plurality of second forced reduction nitrogen oxide spray guns 3, and a plurality of second forced nitrogen oxide spray guns 3 are installed on The furnace outlet of the furnace body 1 is in the horizontal flue. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com