Pipeline repairing device and pipeline repairing method

A pipeline repair and pipeline technology, applied in the direction of pipes/pipe joints/fittings, pipe components, special pipes, etc., can solve the problems of cumbersome filling process, achieve the effect of improving rotation accuracy, simplifying the process, and accurate repairing position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

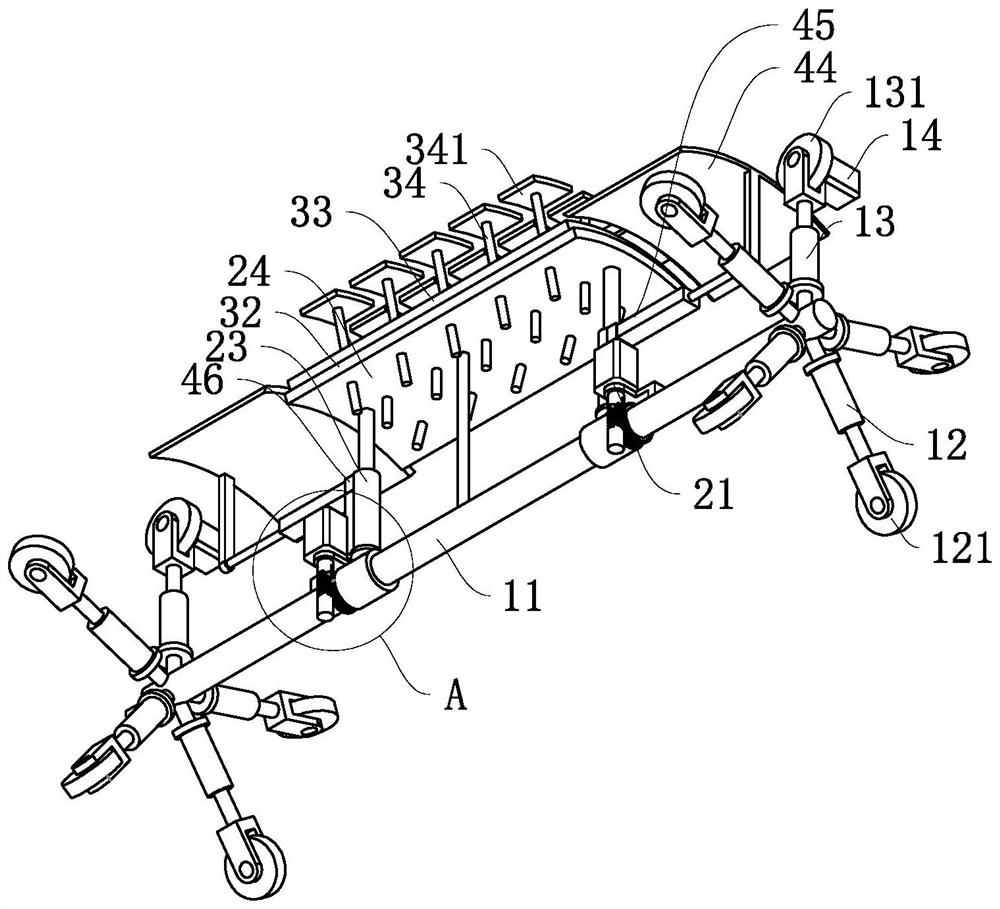

[0048] The following is attached Figure 1-4 The application is described in further detail.

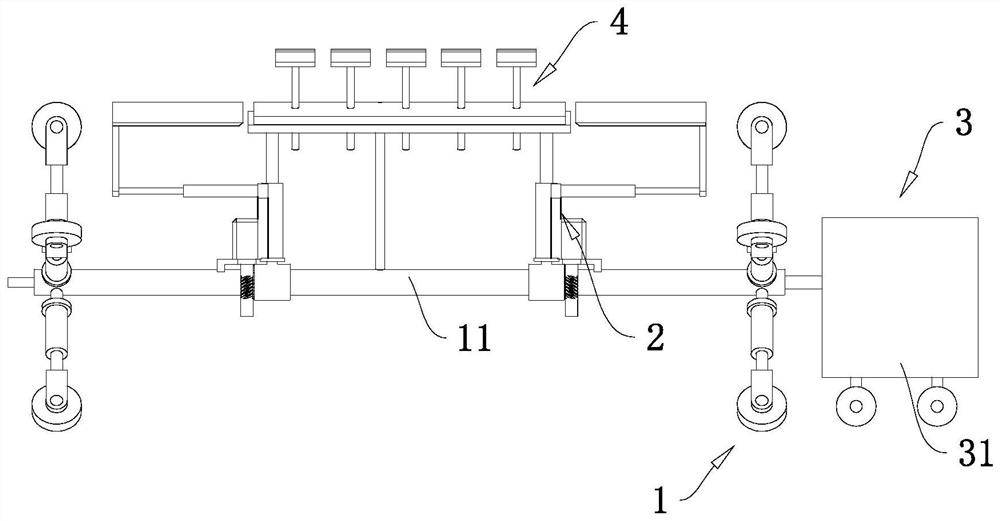

[0049] The embodiment of the present application discloses a pipeline repair device, referring to figure 1 , including a crawler device 1 , a mounting bracket 2 , a gap detection component 3 and a gap filling component 4 . The installation bracket 2 is installed on the crawling bracket 1 and is used for the installation of the gap detection component 3 and the gap filling component 4. The gap detection component 3 detects the gap on the pipeline, and the gap filling component 4 fills the gap detected by the gap detection component 3. .

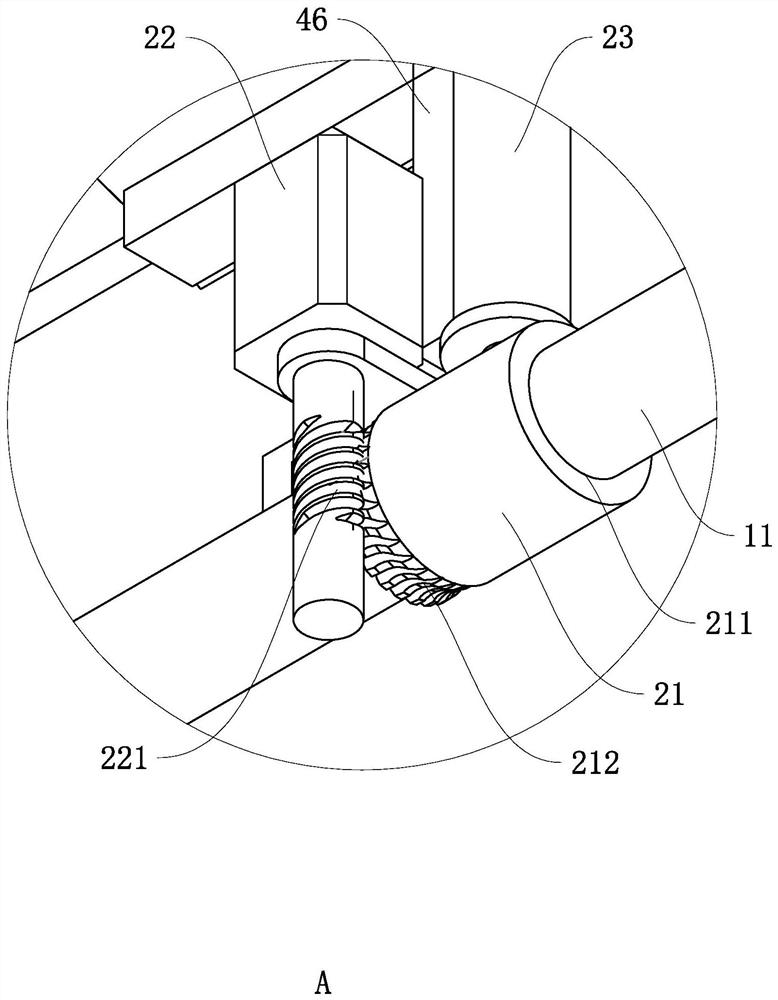

[0050] refer to figure 1 and figure 2 , the crawling device 1 includes a crawling pole 11, a moving pole 12 arranged at intervals along the length direction of the crawling pole 11, an active pole 13 arranged on the side wall of the crawling pole 11, and a crawling driver for driving the active pole 13 to move 14.

[0051] The moving struts 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com