Wheel-legged type reducing pipeline inner wall crawling robot

A crawling robot and pipeline technology, applied in the direction of pipe components, special pipes, mechanical equipment, etc., can solve the problems of old-fashioned mechanism, single function, inability to meet the use, etc., and achieve the effect of maintaining stability and flexible turning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] First, in this embodiment, the forward direction of this embodiment is taken as the front-rear direction, and the vertical direction is distinguished by the direction of gravity.

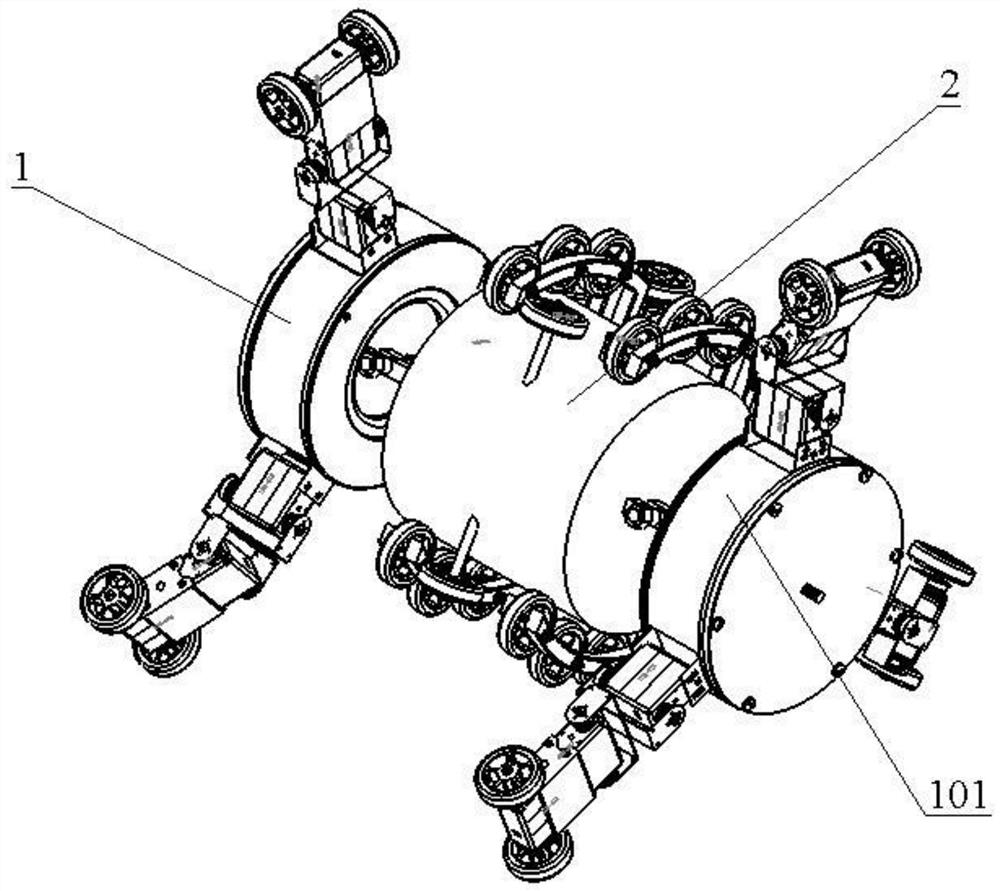

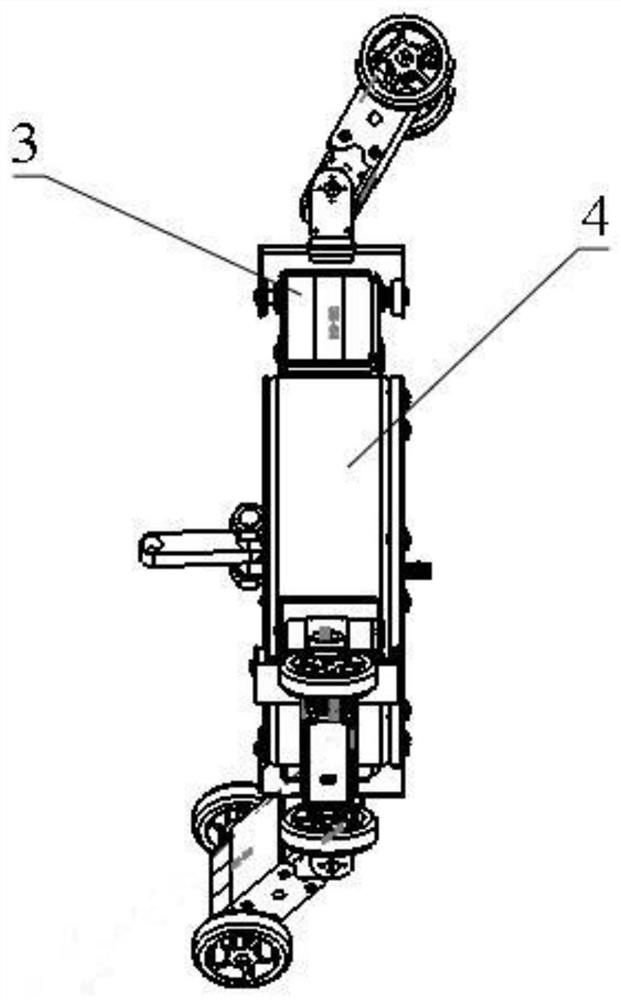

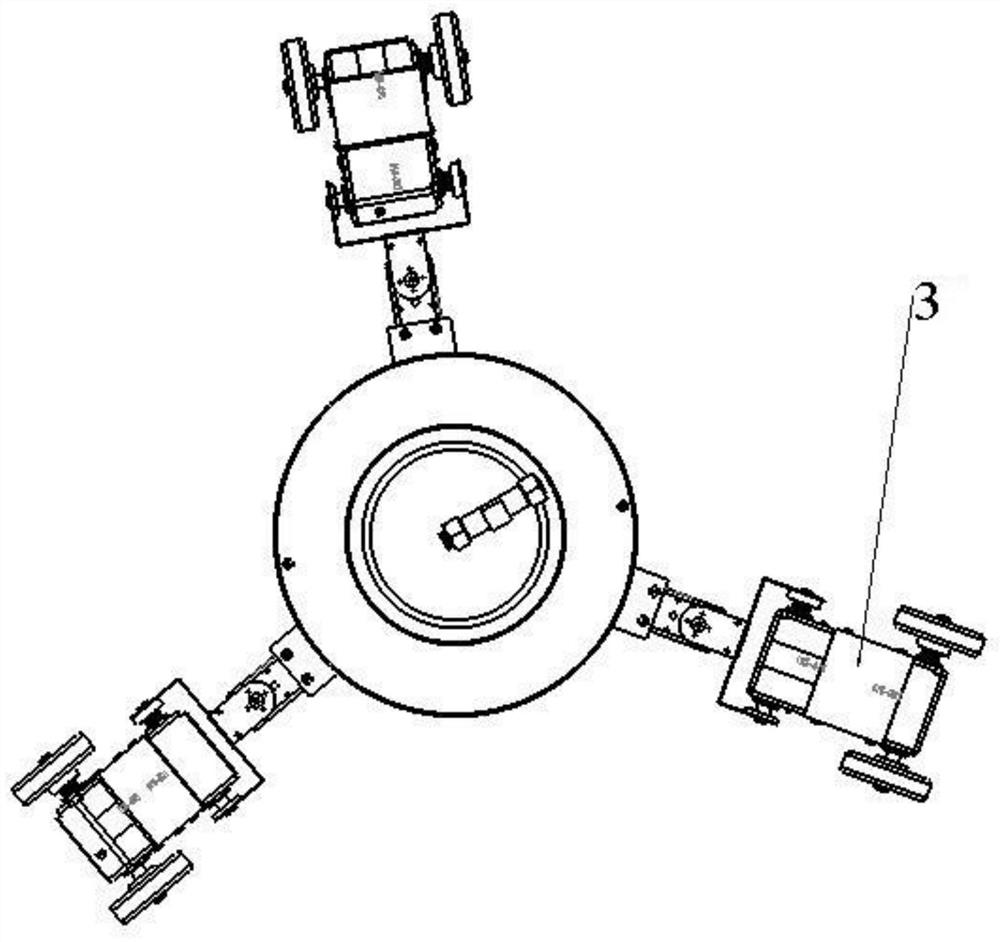

[0047] see figure 1 , the present embodiment provides a wheel-leg crawling robot on the inner wall of a variable-diameter pipeline, including a vehicle body 2 , and a first power body 1 and a second power body 101 arranged on both sides of the vehicle body 2 . The first power body 1 and the second power body 101 are used to provide power and drive the vehicle body 2 to move.

[0048] Specifically, see figure 1 , the first power body 1 is provided with a first connecting rod that is movably connected with it through a stud bolt, and the second power body 101 is provided with a second connecting rod that is movably connected with it through a stud bolt. A connecting rod is connected with the vehicle body 2, and the second power body 101 is connected with the vehicle body 2 through the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com