Valve assembling part wide in application range

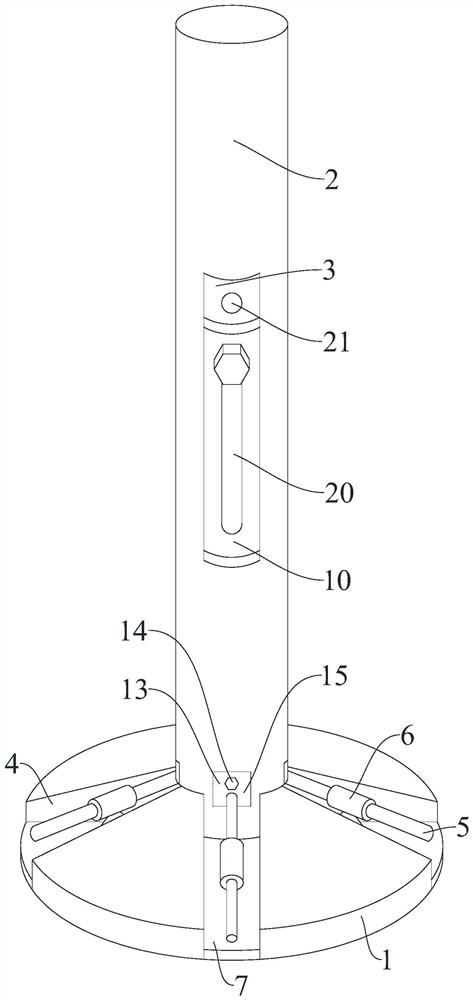

A technology of application scope and assembly parts, applied in valve device, valve operation/release device, valve details, etc., can solve the problems of troublesome installation, disassembly and maintenance, limited valve installation position, single application scope, etc., to improve assembly stability. and firmness, convenient storage and transportation, easy adjustment and reset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

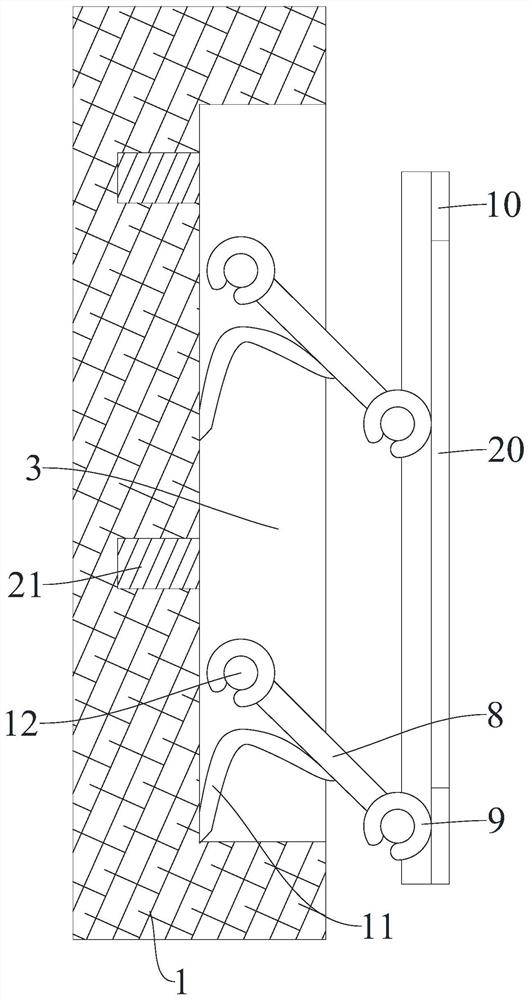

[0026] Embodiment: A loading and unloading gap is provided on the movable connecting cylinder 9, and the loading and unloading is facilitated through the loading and unloading gap, and then the internal extrusion shrapnel 11 is a U-shaped structural shrapnel, which is the same as extruding the external assembly extrusion plate 10 on the inside and turning outward to form an internal Elastic squeeze.

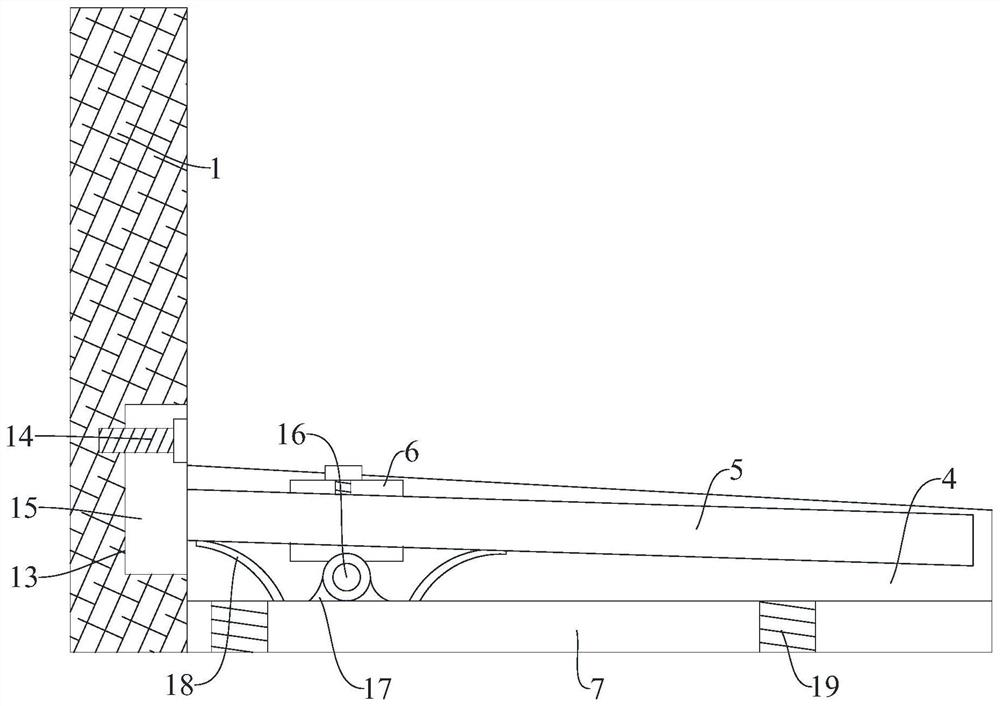

[0027] Further, in order to cooperate with the lateral assembly and fixation, the lower end of the outer surface of the valve stem connector 1 is provided with a lateral installation groove 13 for installing the lateral telescopic rod 5, and the top end of the lateral telescopic rod 5 has an integrated structural assembly block with built-in assembly bolts 14 15. The lateral telescopic rod 5 is screwed into the lateral installation groove 13 through the assembly bolt 14 and is fixedly connected with the valve stem connector 1. Furthermore, in order to cooperate with the movable as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com