Production method of gasoline and low-sulfur marine fuel

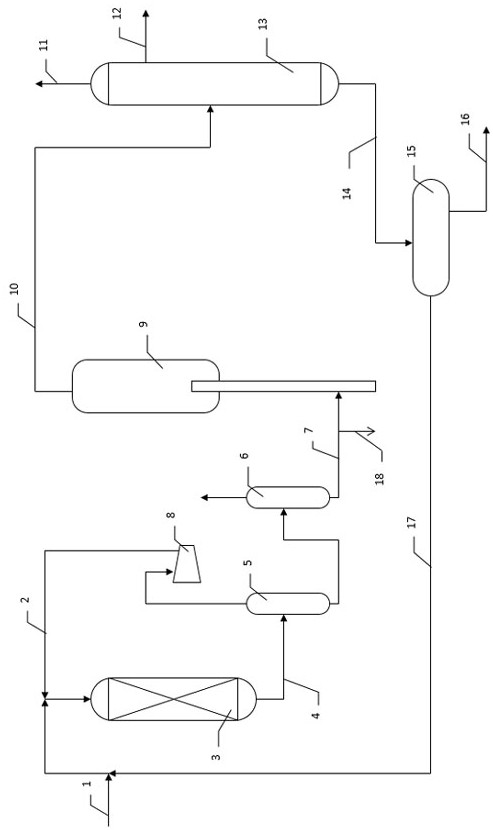

A production method and technology for low-sulfur ships, which are mainly used in the field of gasoline and low-sulfur marine fuel production, can solve the problems of insufficient utilization of re-refined oil and oil slurry, difficult diesel processing, low gasoline yield, etc., and achieve reduction Difficulty of hydrogenation reaction and processing severity, improvement of logistics distribution and mass transfer, and the effect of improving oil properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment adopts the production method of gasoline and low-sulfur marine fuel provided by the present invention, and uses inferior residual oil raw material A. It can be seen that the sulfur content of residual oil is as high as 4.15wt%, residual carbon is 13.48wt%, and metal (Ni+V) is 92µg / g, with a total nitrogen content of 0.30%, belongs to the high-sulfur low-quality residual oil.

[0041] The device adopts four fixed-bed reactors connected in series, one of which is filled with three kinds of residue hydrogenation protection agents, and the filling volume is 18mL of FZC-12B catalyst, 20mL of FZC-103D catalyst, and 22mL of FZC-103E catalyst; One kind of residue hydrodemetallization catalyst, the loading volume is 85mL for FZC-28A catalyst, and 140mL for FZC-204 catalyst; one kind of residual oil hydrodesulfurization catalyst FZC-34A is loaded in three reverses, and the filling volume is 165mL; A residual oil hydrodenitrogenation and carbon removal catalyst FZ...

Embodiment 2

[0044] Embodiment 2 adopts the production method of gasoline and low-sulfur marine fuel provided by the present invention, and uses inferior residual oil raw material B, and the properties of the residual oil raw material are shown in Table 1. It can be seen that the residual oil has a sulfur content of 1.65wt%, a nitrogen content of 5200µg / g, a Kangxi residual carbon of 10.56wt%, and a metal (Ni+V) of 50µg / g, which belong to low-sulfur and high-nitrogen low-quality residual oil.

[0045] The hydrogenation unit adopts four fixed-bed reactors in series, one of which is filled with three kinds of residue hydrogenation protection agents, and the filling volume is 12mL of FZC-12B catalyst, 18mL of FZC-103D catalyst, and 30mL of FZC-103E catalyst; Two kinds of residual oil hydrogenation and demetallization are loaded, and the loading volumes are 74mL for FZC-28A catalyst and 132mL for FZC-204 catalyst; one kind of residual oil hydrodesulfurization catalyst FZC-34A is loaded for the ...

Embodiment 3

[0048] The same as in Example 1, the difference is that the catalyst loading method in the hydrogenation unit is as follows: one of them reversely loads two kinds of residue hydrogenation protection agents, and the loading volumes are respectively 8mL of FZC-12B catalyst and 17mL of FZC-103E catalyst; A residual oil hydrodemetallization catalyst, with a loading volume of 150mL for FZC-28A catalyst and 125mL for FZC-204 catalyst; and a residual oil hydrodesulfurization catalyst FZC-34A, with a loading volume of 200mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com