Wet oxidation desulfurization system for Claus hydrogenation tail gas, and desulfurizationmethod thereof

A wet oxidation and desulfurization system technology, applied in chemical instruments and methods, separation methods, sulfur preparation/purification, etc., can solve the problems of high energy consumption for regulation, poor sulfur quality, secondary pollution, etc., and achieve the reduction of hydrogen sulfide Concentration, separation of sulfur, and effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

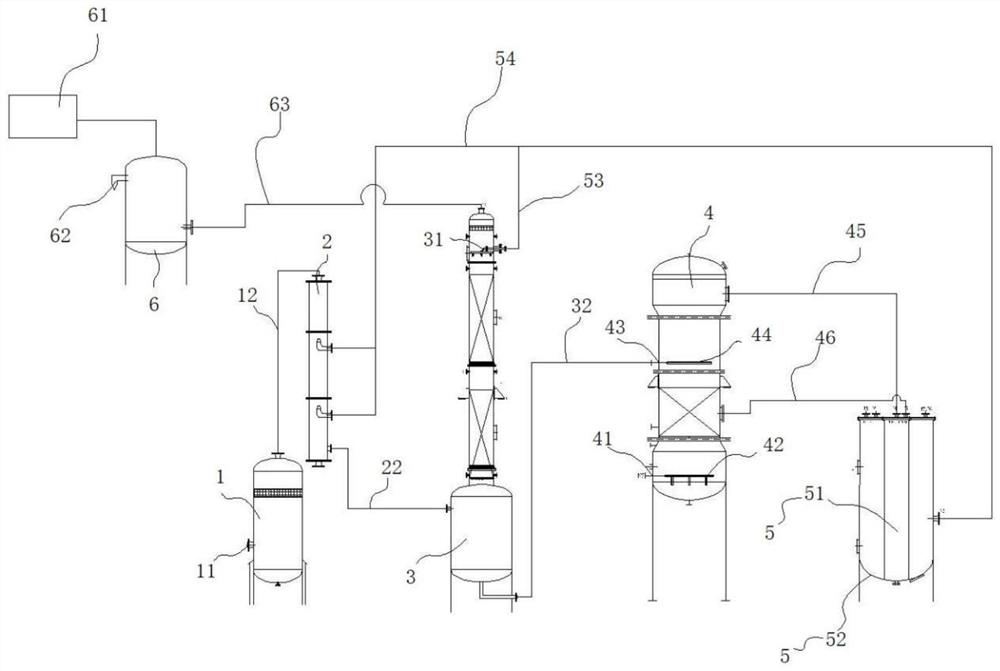

[0076] A Claus hydrogenation tail gas wet oxidation desulfurization system, such as figure 1 As shown, it includes buffer tank 1, power wave scrubber 2, absorption tower 3, regeneration tower 4, settling tank 5, washing tank 6 and filter bag centrifuge (not shown); wherein the model of filter bag centrifuge is PSB600;

[0077] The buffer tank 1 is provided with an air inlet 11, and the Claus hydrogenation tail gas enters the buffer tank 1 from the inlet 11 to separate gas and liquid. The top wall of the buffer tank 1 is connected with the first pipeline 12, and the first pipeline 12 A first valve (not shown) and a booster fan (not shown) are installed on the top, wherein the installation method of the booster fan and the first valve is the prior art; the booster fan is a Roots blower, and the wind power of the booster fan The adjusted pressure is 10-98kpa;

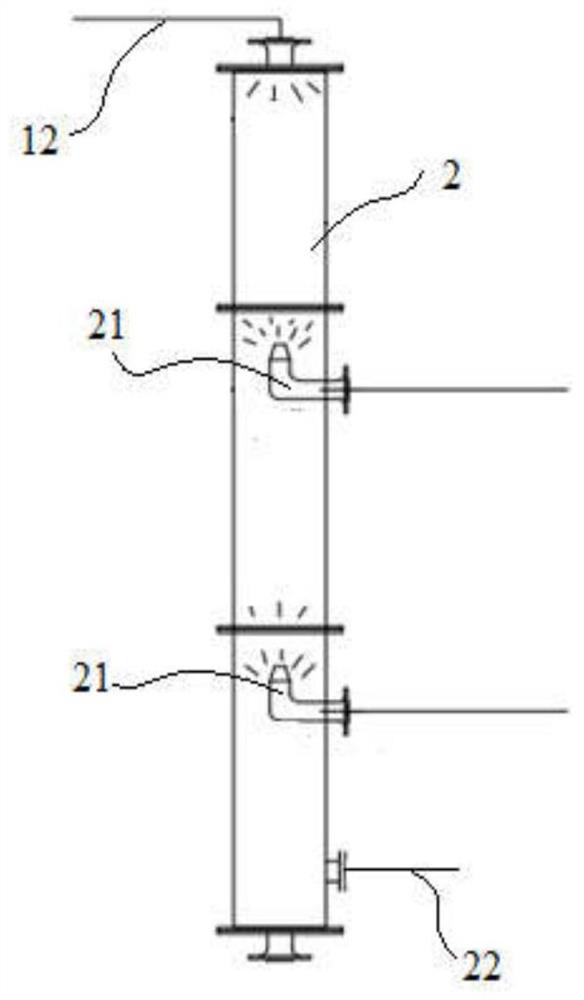

[0078] Such as figure 2 As shown, the first nozzle 21 is installed in the power wave scrubber 2, and the number of t...

Embodiment 2

[0098] Preparation method of desulfurization liquid

[0099] Made of iron-based ionic liquid and organic solvent, the volume ratio of iron-based ionic liquid and organic solvent is 2:1, and the organic solvent in this embodiment is dimethylacetamide.

[0100] The preparation method of the iron-based ionic liquid comprises the following steps: mixing methylimidazole and n-butane chloride according to a molar ratio of 1:1, reacting for 72 hours under the condition of reflux at 80° C. to prepare alkylimidazole chloride, and then Alkylimidazole chloride and ferric chloride are mixed at a molar ratio of 1:2 to prepare an iron-based ionic liquid.

[0101] The desulfurization solution in this embodiment does not need to strictly control the pH value, and is applicable to a wide range of temperatures.

Embodiment 3

[0103] The difference between this example and Example 2 is that the organic solvent is N-methylpyrrolidone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com