Glass-packaged ceramic feed-through filter and preparation method thereof

A feed-through filter and glass packaging technology, applied in the field of capacitors, can solve problems such as flux residues, and achieve the effects of avoiding residues, increasing size, and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

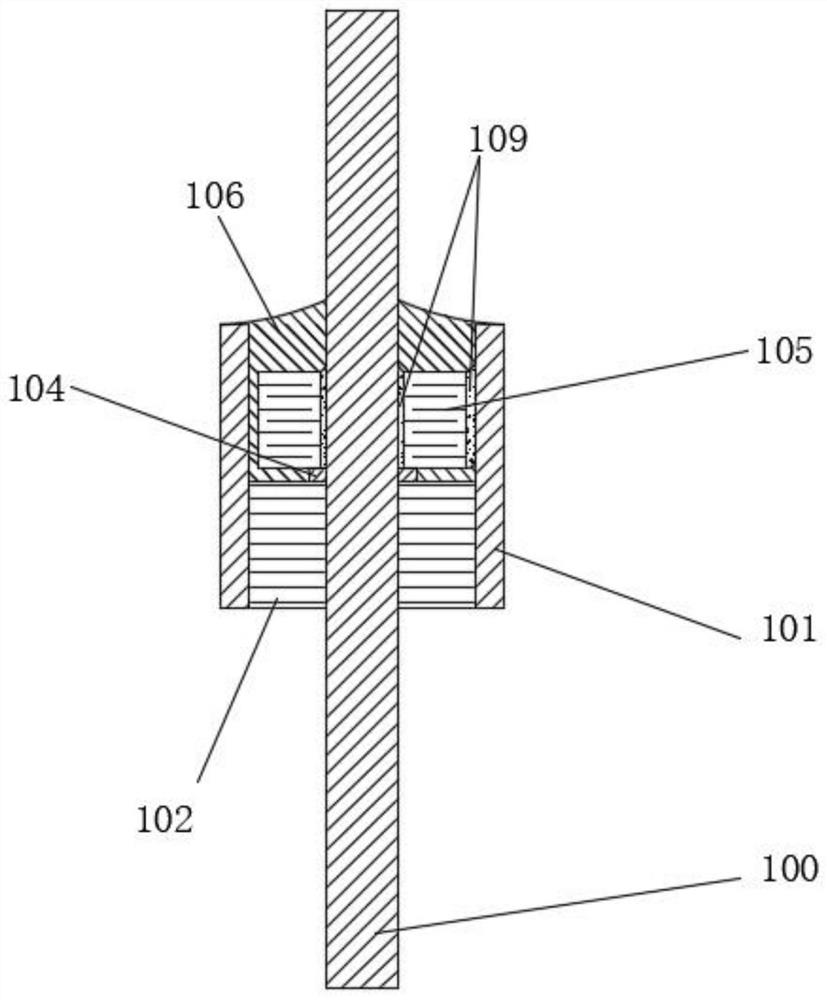

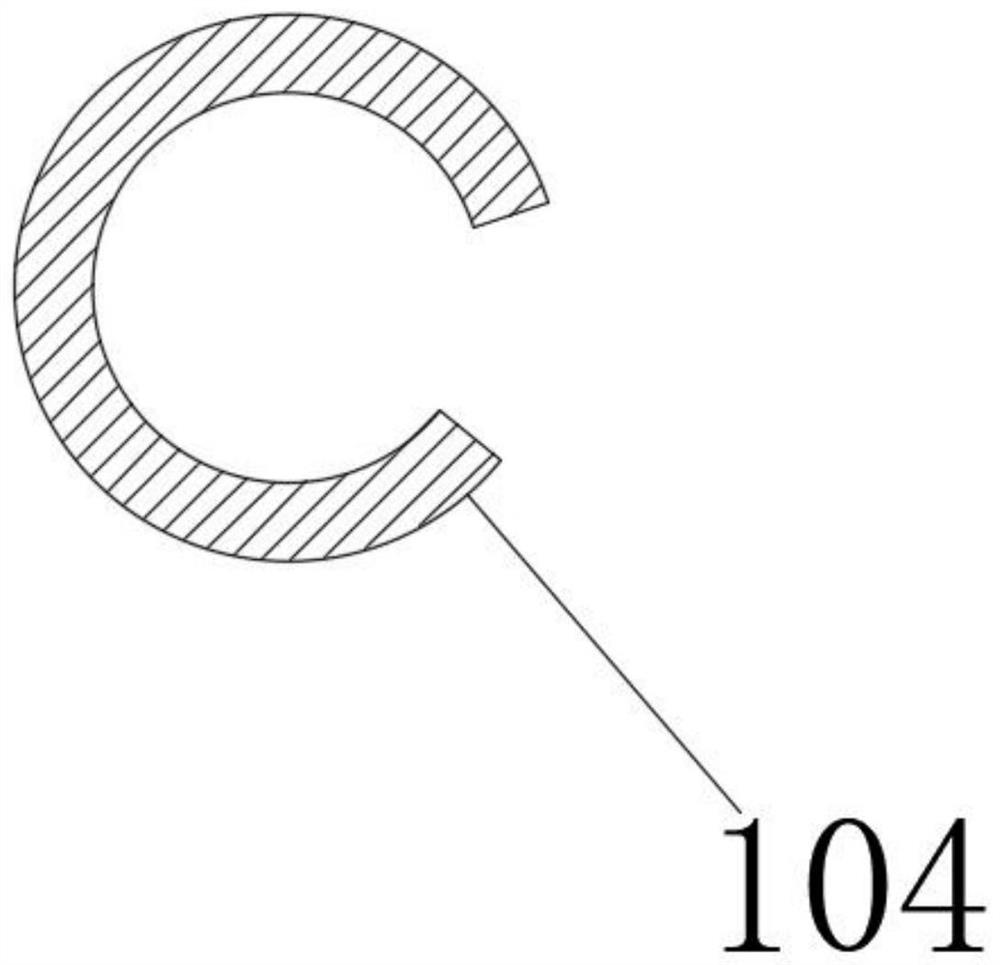

[0033] Such as Figure 1-3 Illustrated, a glass-ceramic feedthrough filter package, comprising a needle guide sleeve 100 and the metal housing 100 is provided in the middle of the guide pin 101; bottom 101 of the metal shell 102 is fixed by a glass body and hermetically connected to the guide pin 100 The package of the end portion of the metal casing 101 is formed over the glass body 102, and a receiving chamber 103 is formed inside the metal casing 101, and the glass body 102 is provided with a spacer 104 in the guide pin 100; the gasket 104 The guide pin 100 is provided with a disc multilayer ceramic capacitor 105; the bottom portion of the disc multilayer ceramic capacitor 105 is formed with a first gap 107 at the top of the glass body 102; the disk multilayer ceramic capacitor 105 welding fixation in the receiving chamber 103; between the inner wall of the disc-shaped multilayer ceramic capacitor 105 and the metal housing 101 or outside of the guide pin 100 is formed with at le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com