Power battery pulse heating reliability test method

A power battery and pulse heating technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., it can solve the problems of long waiting time for heating, small heating rate, easy lithium precipitation of batteries, etc., so as to reduce the time of manual operation. , The effect of reducing the test cost and simplifying the operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

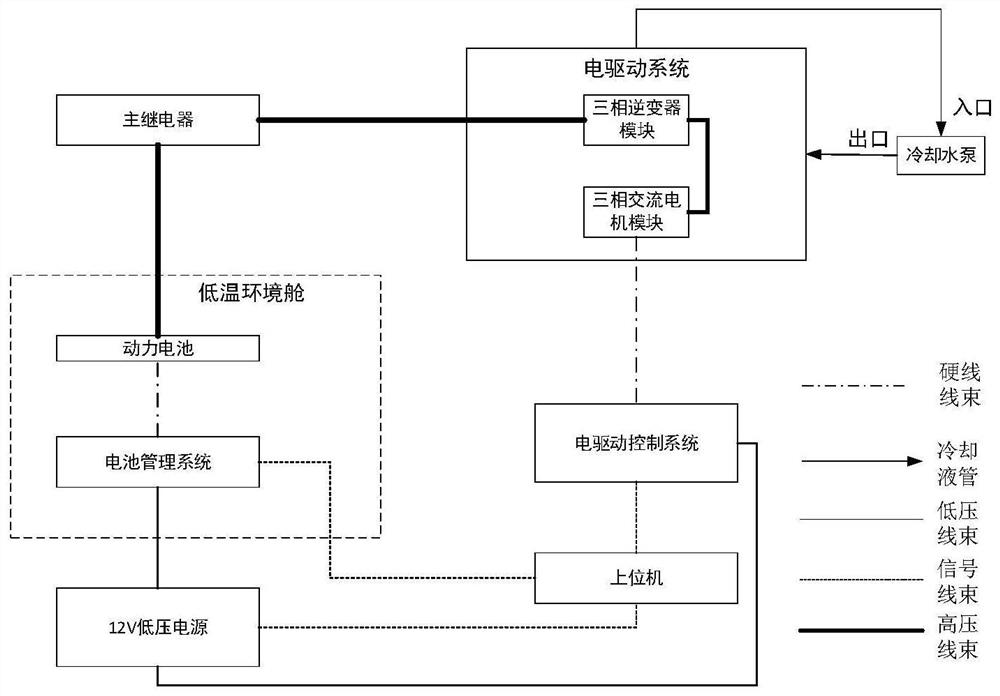

[0032] Next, the embodiment of the present invention and the actual operation process of automatically controlling the pulse heating function of the bench to be turned on and off will be described in combination with the design schematic diagram of the present invention. Since it is necessary to protect the core technical points of the present invention, the illustrated embodiments are only part of the content of the present invention, but all belong to the protection scope of the present invention.

[0033] An embodiment of the present invention provides a power battery pulse heating reliability test method, which is used to verify the impact of power battery capacity decay after pulse heating of the power battery by a pulse current with a specific heating frequency and amplitude.

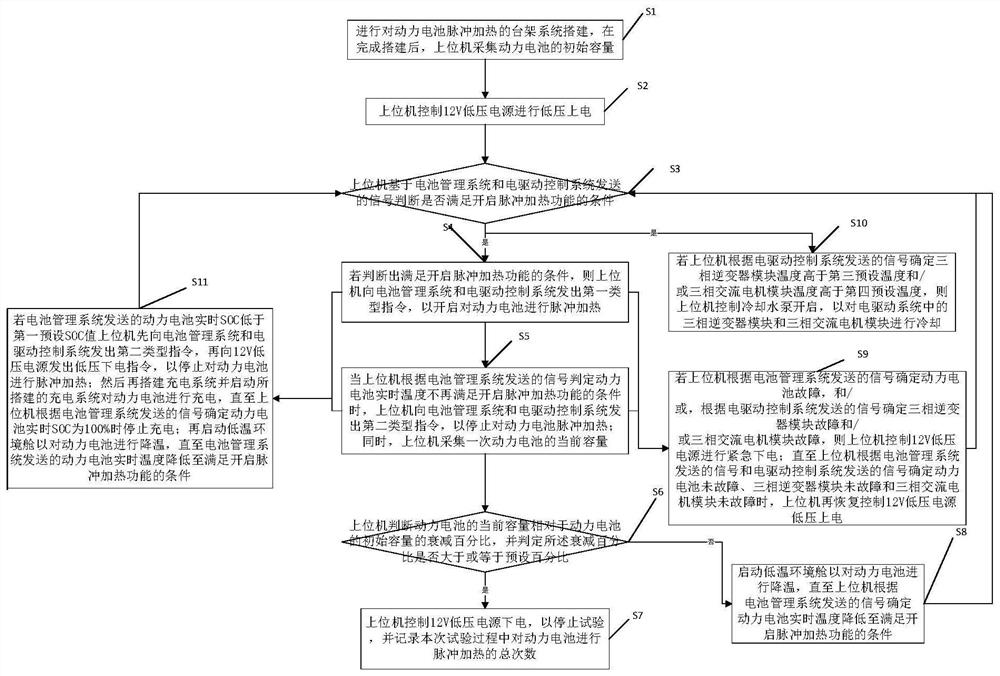

[0034] refer to figure 2 , the method includes in the embodiment of the present invention:

[0035] Step S1, build the bench system; after the build is completed, the host computer collects the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com