All-solid-state battery reaction chamber for in-situ XRD and Raman test and test method

A technology of all-solid-state batteries and solid-state batteries, which is applied in battery assembly machines, secondary battery manufacturing, non-aqueous electrolyte storage batteries, etc., can solve problems such as simplification of device functions, incompatibility of devices, and single testing methods, and achieve uniform current density , No miscellaneous peak interference, good equipment versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] In situ XRD detection of solid-state battery assembly

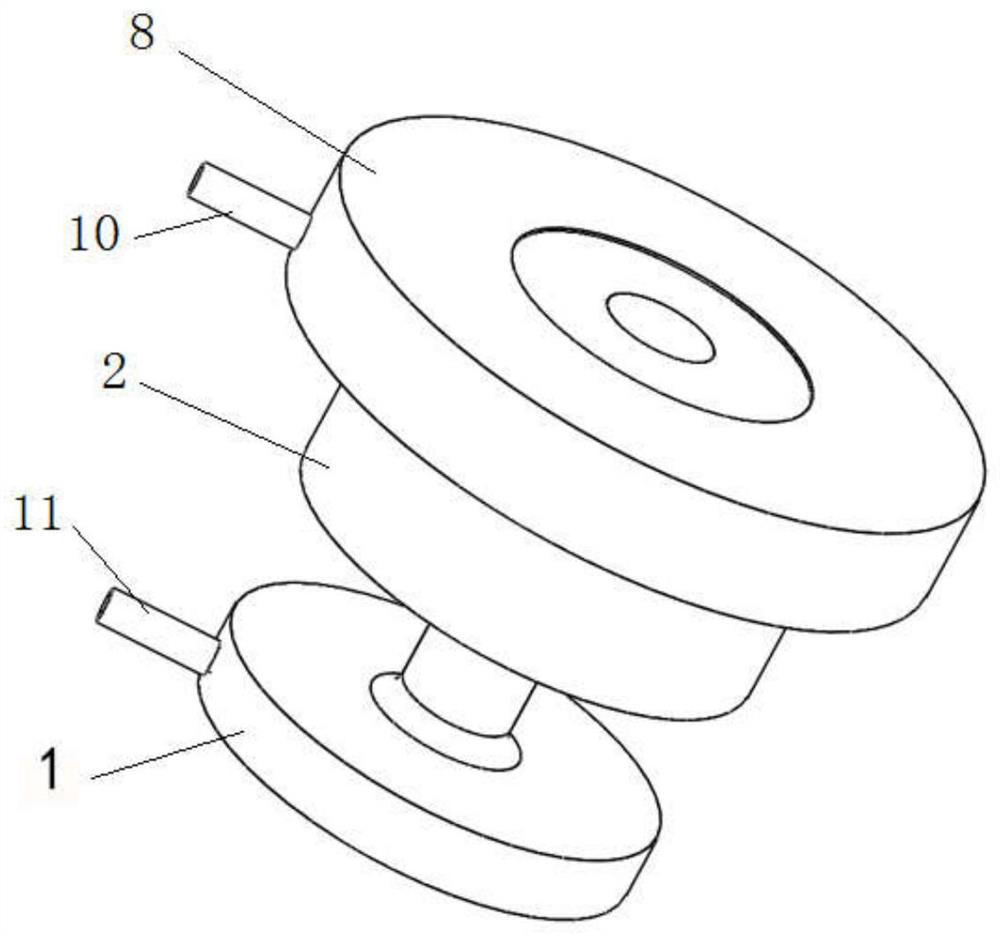

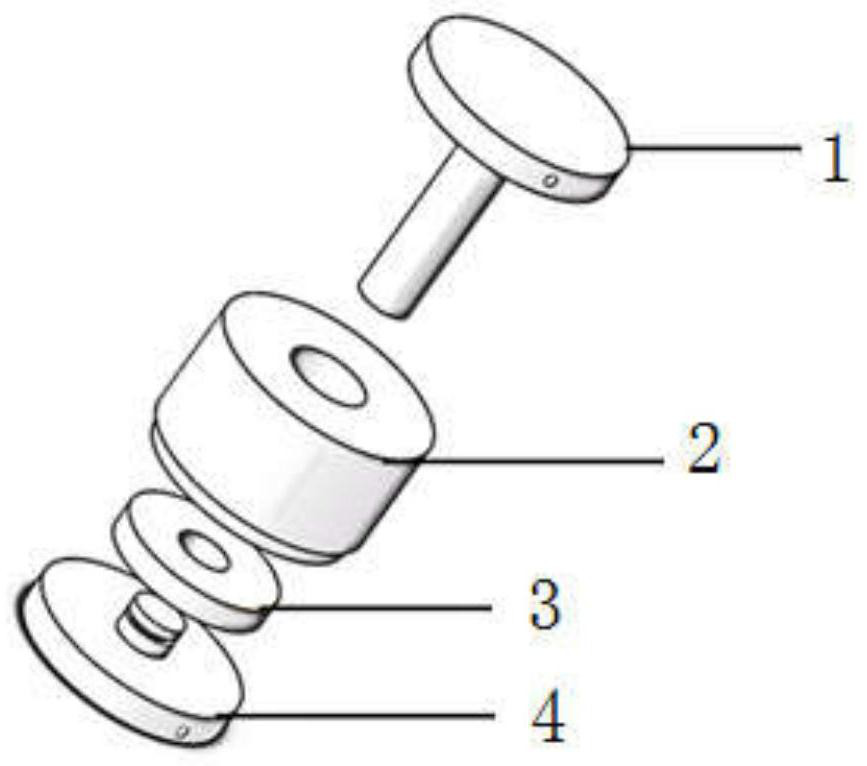

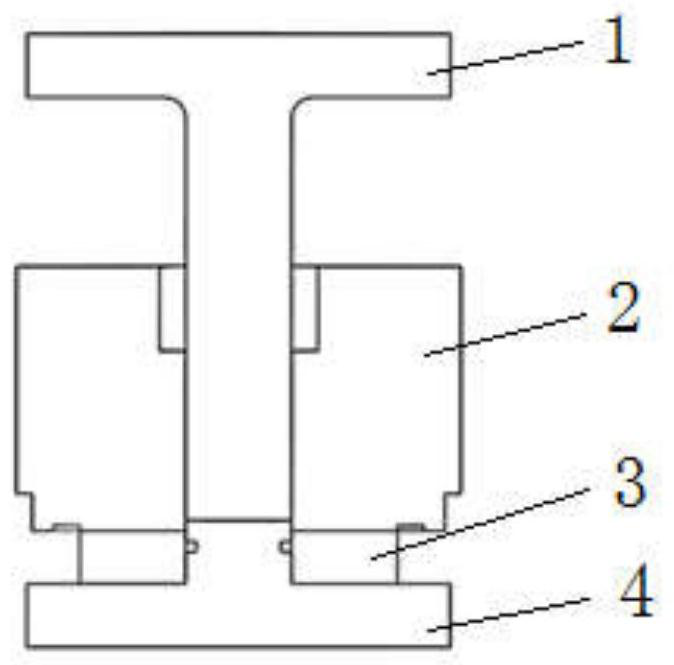

[0062] like Figure 2-3 As shown, put the upper mold core 1 into the die cavity 2 of the solid-state battery mold case 2, and then add 80mg Li to the die cavity 6 P.S. 5 C1, put the pressure ring 3 on the counter electrode seat 4, and then put the counter electrode seat 4 into the die cavity of the solid-state battery mold case 2. The solid battery mold equipped with the upper mold core 1 and the counter electrode holder 4 is placed in the inner cavity of the hydraulic press, and the solid electrolyte is pressed into thin sheets under a pressure of 2 MPa.

[0063] like Figure 3-4 As shown, carefully remove the counter electrode holder 4, and put 10mg composite positive electrode material (LiCoO 2 with Li 6 P.S. 5 Cl mass ratio 7:3) was added into the die cavity of the solid-state battery mold shell 2, evenly filled on the surface of the electrolyte, and the electrode pressure ring 5 was put on the counter el...

Embodiment 2

[0068] In situ XRD detection of solid-state battery assembly

[0069] Put the upper mold core 1 into the die cavity of the solid-state battery mold case 2, and then add 80mgLi 10 GeP 2 S 12 , put the pressure ring 3 on the counter electrode seat 4, and then put the counter electrode seat 4 into the die cavity of the solid state battery mold case 2. The solid battery mold equipped with the upper mold core 1 and the counter electrode holder 4 is placed in the inner cavity of the hydraulic press, and the solid electrolyte is pressed into thin sheets under a pressure of 2 MPa.

[0070] Carefully take off the opposite electrode seat 4, put 10mg composite positive electrode material (LiCoO 2 with Li 10 GeP 2 S 12 mass ratio 7:3) into the die cavity of the solid-state battery mold case 2, evenly spread on the surface of the electrolyte, put the electrode pressure ring 5 on the counter electrode seat 4, and then under the pressure of 8Mpa, the positive electrode material and the...

Embodiment 3

[0074] In situ Raman detection of solid-state battery assembly

[0075] Put the upper mold core 1 into the die cavity of the solid-state battery mold case 2, and then add 80mgLi 6 P.S. 5 C1, put the pressure ring 3 on the counter electrode seat 4, and then put the counter electrode seat 4 into the die cavity of the solid-state battery mold case 2. The solid battery mold equipped with the upper mold core 1 and the counter electrode holder 4 is placed in the inner cavity of the hydraulic press, and the solid electrolyte is pressed into thin sheets under a pressure of 2 MPa. Carefully take off the opposite electrode seat 4, put 10mg composite positive electrode material (LiCoO 2 with Li 6 P.S. 5 Cl mass ratio 7:3) was added to the cavity 2 of the die of the shell, evenly filled on the surface of the electrolyte, and the electrode pressure ring 5 was put on the counter electrode seat 4, and then the positive electrode material and the solid electrolyte were tightly pressed und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com