A preparation device and method for a rock-soil model test piece

A technology for model testing and preparation of devices, applied in the field of geotechnical engineering, can solve problems such as seepage, change of similar material ratio, cumbersome process, etc., and achieve the effects of improving utilization efficiency, ensuring integrity, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

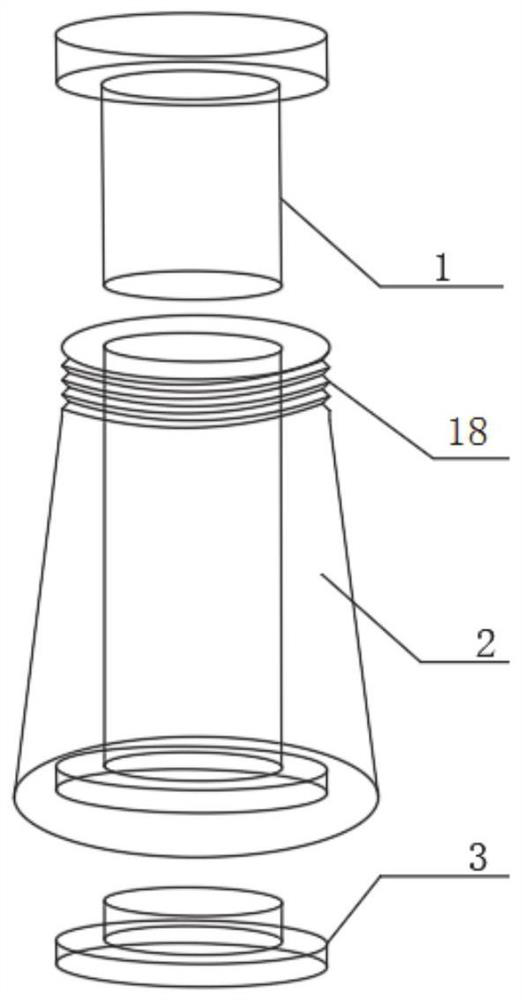

[0049] Such as figure 1 As shown, this embodiment provides a preparation device for a rock-soil model test piece, including a mold cylinder 2, a hammer 1 that can be inserted from the opening of the first end of the mold cylinder 2, and a hammer that is detachably installed at the opening of the second end. Base 3.

[0050] It can be understood that, in this embodiment, the hammering component can rely on its own gravity, or transmit an external hammering force to the untamped test piece.

[0051] It can be understood that the base and the mold cylinder in this embodiment are detachably connected. In one of the connection methods, an external thread can be provided on the outer circular side of the base, and the same mold cylinder inner cavity can be provided at the lower end of the mold cylinder. The threaded hole of the shaft makes the base and the mold barrel fixed by threads. In some other embodiments, the detachable fixing of the two can be achieved by means of hoop con...

Embodiment 2

[0067] This embodiment provides a method for preparing a rock-soil model test piece, utilizing the above-mentioned preparation device for a rock-soil model test piece, comprising the following steps:

[0068] Apply lubricating oil on the inside of the mold cylinder, use the base 3 to block the second end opening of the mold cylinder 2, and fill the mold cylinder 2 with sample materials;

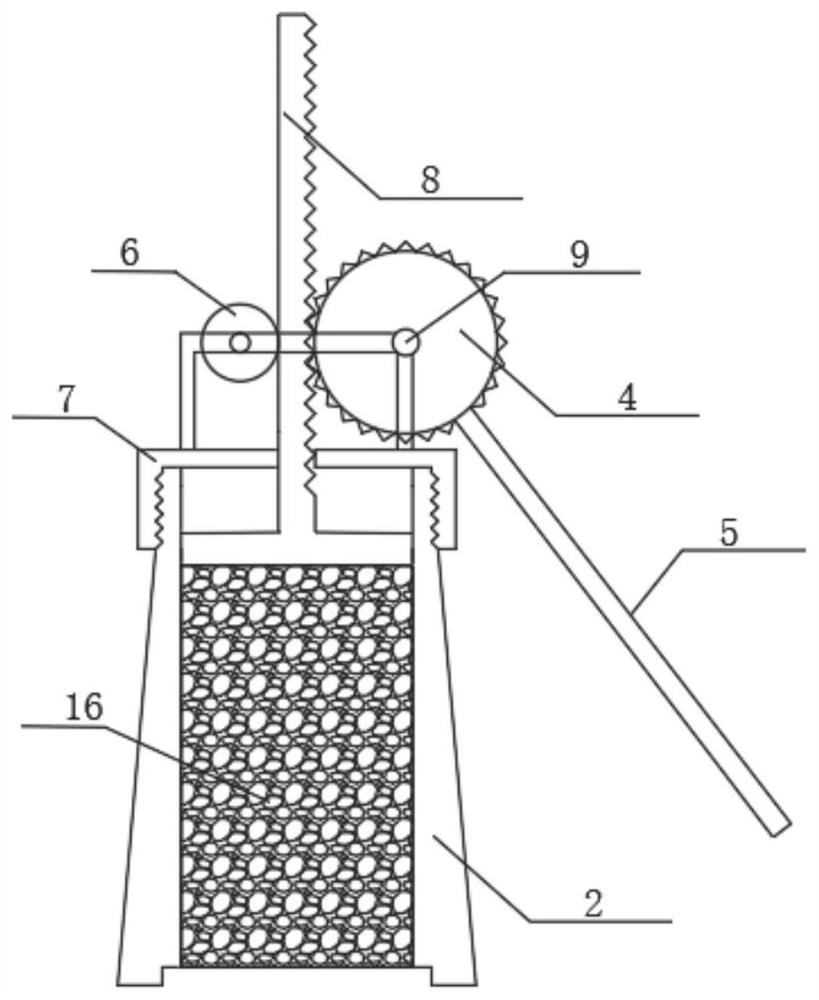

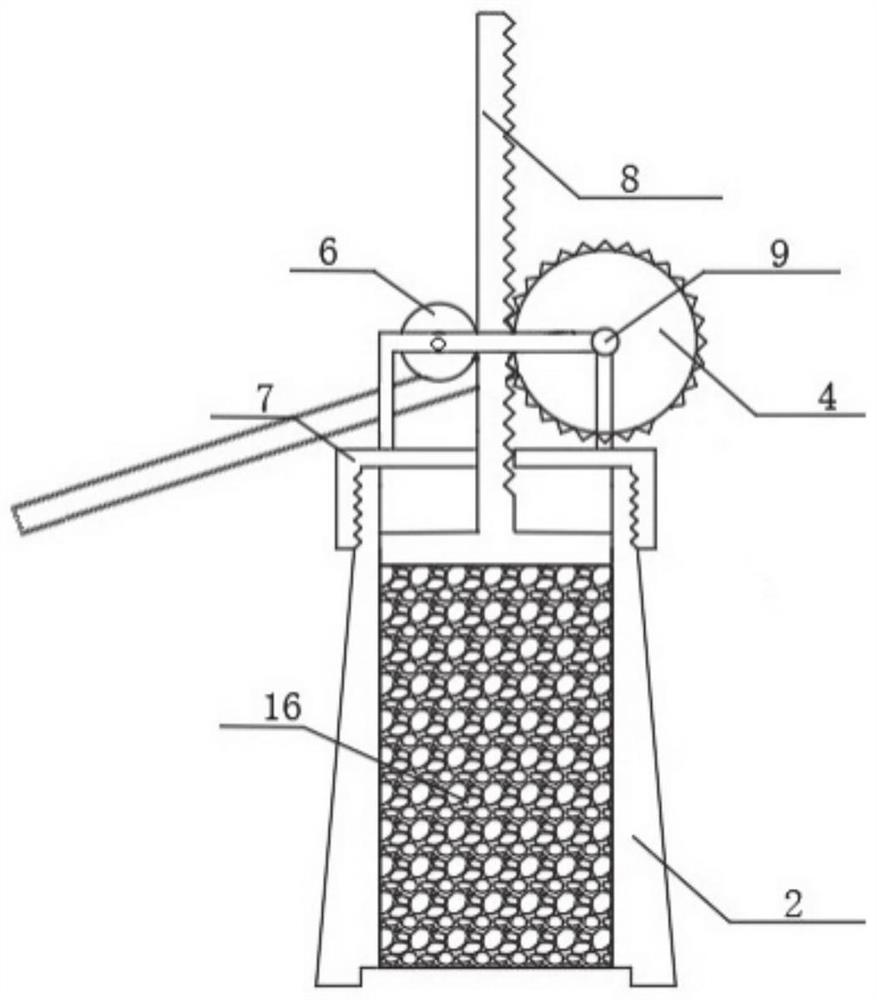

[0069] After the sample material is filled, the sample material in the mold barrel 2 is tamped with a hammering part until the size of the test piece meets the requirements. After the sample material is formed and stabilized, the test piece 16 is formed, and the base 3 and the hammering piece 1 are removed;

[0070] A top cover 7, a push rod 8 and a linear drive mechanism are installed at the opening of the first end of the mold cylinder 2, and the drive of the linear drive mechanism makes the push rod 8 extend into the inner cavity of the mold cylinder 2 and the test piece 16 is ejected from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com