Heat pipe radiator adopting novel phase change materials

A technology of heat pipe radiator and phase change material, which is applied in the field of radiator heat dissipation, can solve the problems of high temperature heat dissipation, slow heat dissipation speed of radiator, etc., and achieve the effect of heat dissipation cycle, remarkable effect and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

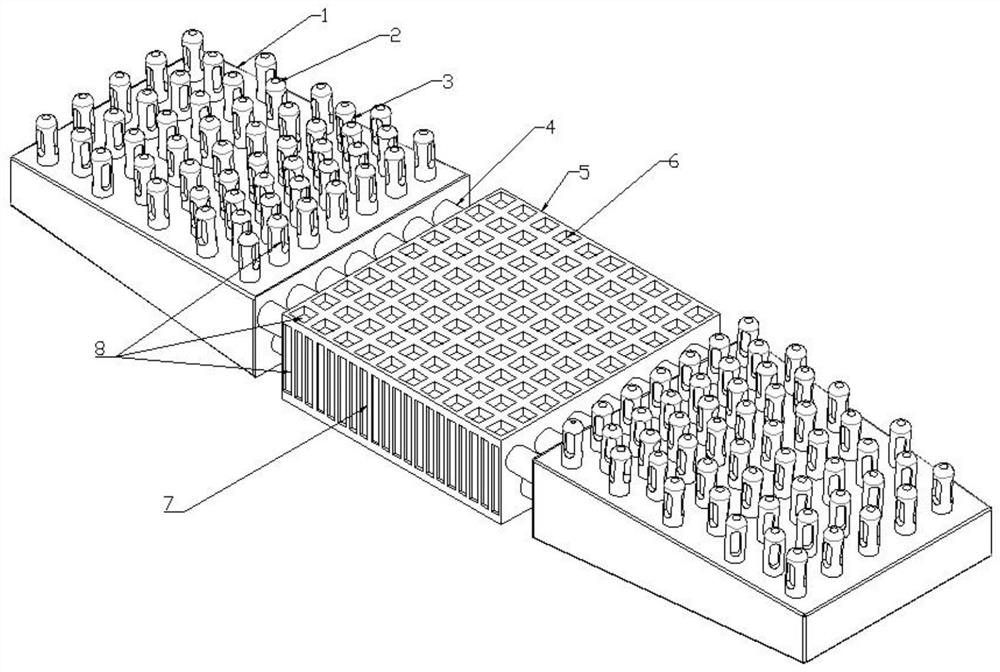

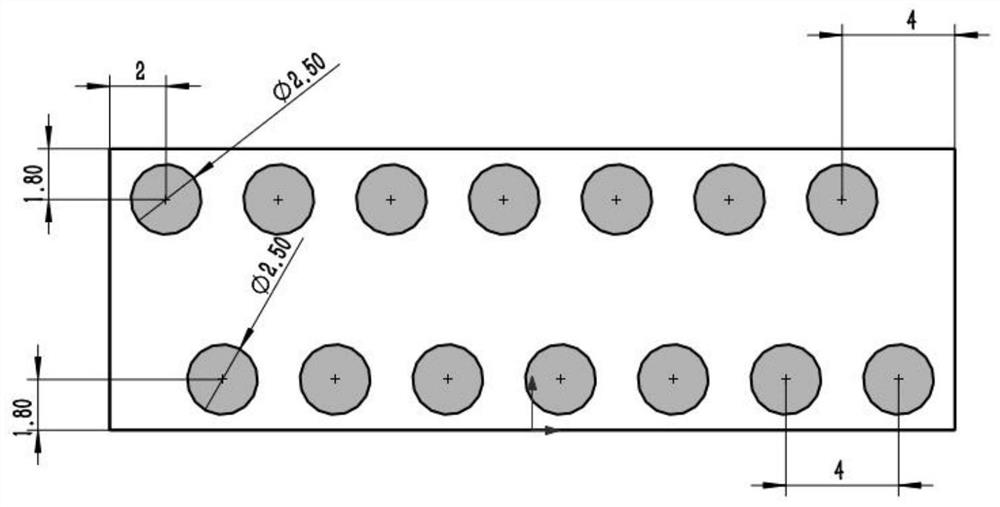

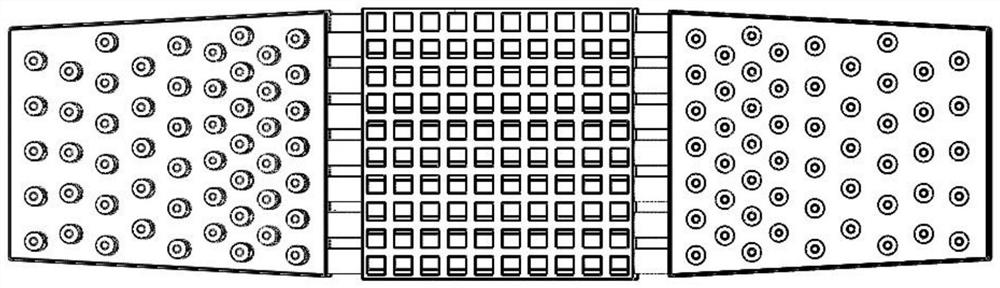

[0042] Such as figure 1As shown, a heat pipe radiator using a new type of phase change material, including a square heat pipe shell 1, a heat dissipation cylinder 2, a keyway 3, a cylindrical shell heat pipe 4, a base plate 5, an upper end gap 6, a left and right end gap 7, a new type Phase change sponge 8, wherein the substrate 5 is made of 20*20mm copper material with a thickness of 10mm, the bottom of the substrate is in contact with the heat source, and absorbs the heat generated by the external system through contact, and the upper end of the substrate is opened 2*2mm The upper end gap, the gap depth is 1mm, and the distance from the edge of the substrate is 0.5mm, the gap between the two upper ends is 1mm, and the number of gaps is 10*10; at the same time, there are 0.5*18mm left and right ends on the left and right sides of the substrate The gap, the distance between the gap and the left and right edges of the substrate is 0.25mm, the distance from the upper and lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com