Swing type temperature measuring device of rapid hardening furnace for rare earth hydrogen storage alloy vacuum induction melting

A vacuum induction melting and hydrogen storage alloy technology, applied in furnaces, furnace materials, crucible furnaces, etc., can solve the problems of low manual detection efficiency, inaccurate temperature values, inaccurate detection data, etc., to ensure processing, easy collection, temperature The effect of accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

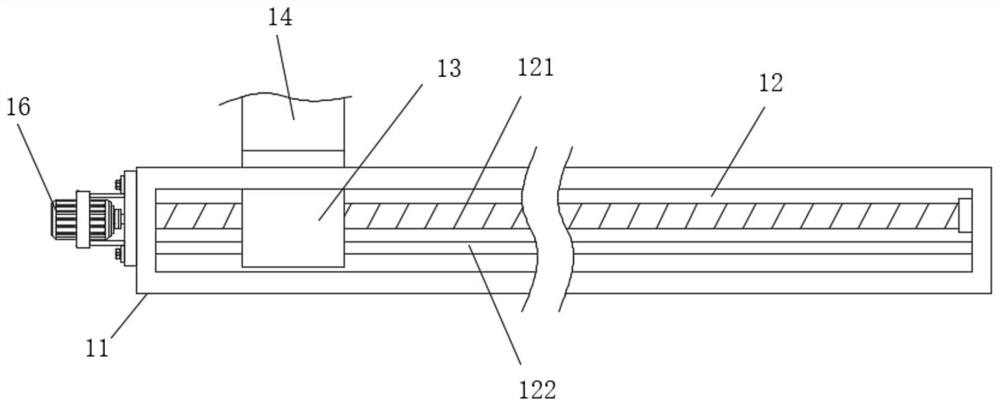

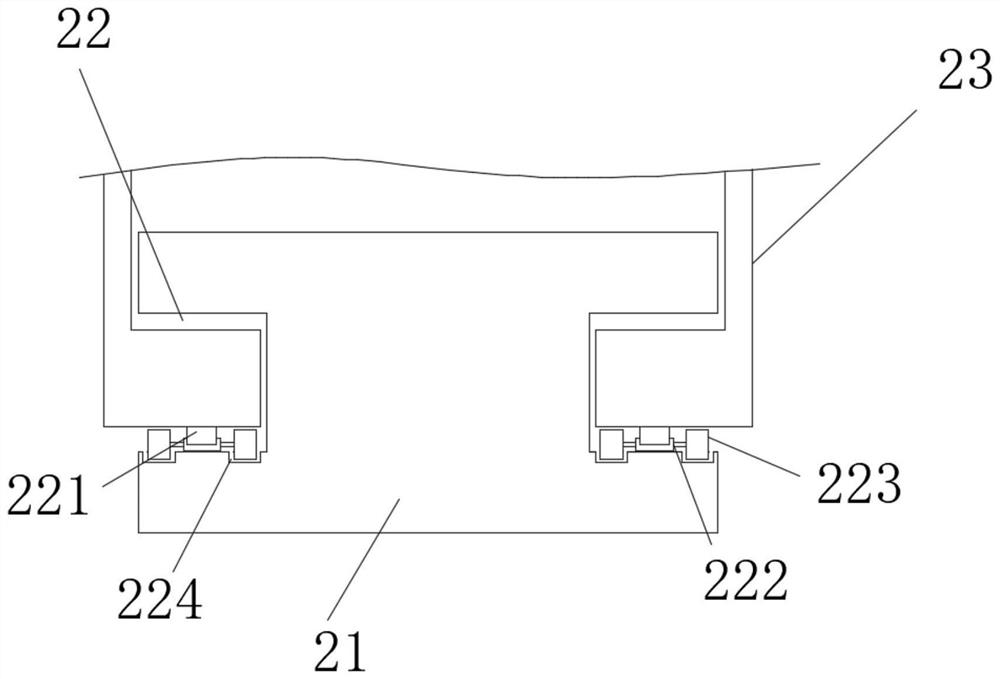

[0025] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a swing-type temperature measuring device for a rare earth hydrogen storage alloy vacuum induction melting quick-setting furnace, including a moving structure 1, and a guiding structure 2 is connected to the moving structure 1. A crossbeam 24 is connected to the guide structure 2, and a rotating structure 3 is connected in the middle of the top of the crossbeam 24, and a range finder 25 is detachably connected to the middle of the side wall of the crossbeam 24 away from the rotating structure 3, and the rotating structure 3 An installation structure 4 is detachably connected to one end away from the guide structure 2, and an infrared thermometer 5 is detachably connected to the installation structure 4;

[0026] The moving structure 1 includes a slide rail 11, the inside of the slide rail 11 is provided with a slide groove 12, and a slide block 13 is slidably connected in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com