Warp knitting machine pattern bar traversing device

A technology of traversing device and machine flower, applied in the field of warp knitting machines, can solve the problems of missing needles, increased production costs, insufficient movement of yarn guide needles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

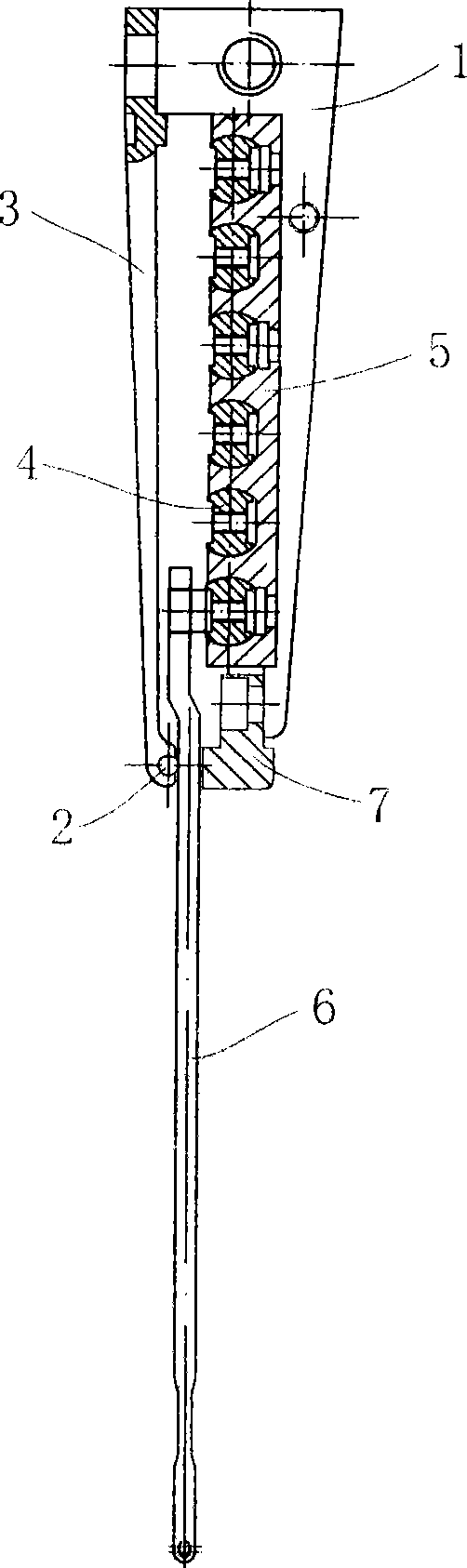

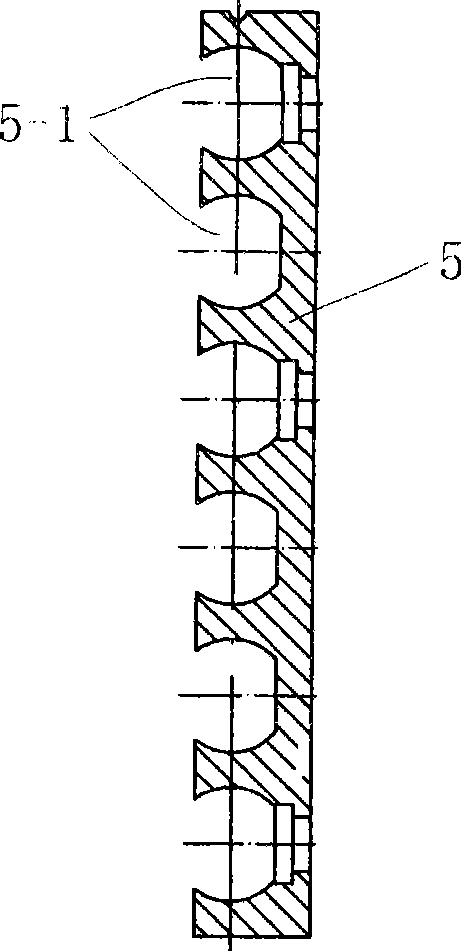

[0019] see Figure 1 to Figure 9 The shown warp knitting machine flower comb traverse device includes a bar seat 1, one end is fixedly connected with the bar seat 1 by a bolt, and the other end passes through a cover plate 3 and a bar 4 for clamping and retaining the needle steel wire 2. Install the guide rail 5 of the comb bar 4 and the yarn guide needle 6 installed on the comb bar 4, the guide rail 5 is fixed on the comb bar seat 1 by a plurality of bolts at a distance from each other in the longitudinal direction, The comb bar 4 is a chamfered cylinder with at least one side chamfered along its axis, and a groove 5-1 which is too small and whose shape matches the chamfered cylinder is provided on the guide rail 5 .

[0020] See Figure 4 to Image 6 , the comb bar 4 is a chamfered cylinder along both sides of its axis, and a guide groove 4-1 for installing the guide needle 6 is provided on at least one side of the chamfered plane, and along the The guide grooves 4-1 are sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com