Threaded grouting sleeve for three-parallel-bar connection in shape like Chinese character 'pin'

A technology of grouting sleeves and finished reinforcements, applied in the direction of structural elements, building components, building reinforcements, etc., can solve problems such as difficulties in concrete pouring, inability to obtain diameter steel bars or reinforcements, and inability to arrange, and achieve external dimensions and occupied volumes Small size, simple structure, easy to make and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

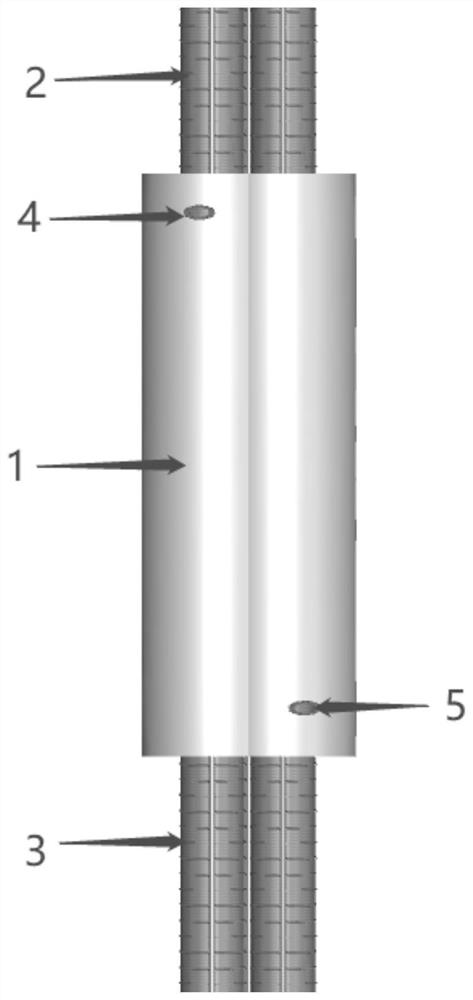

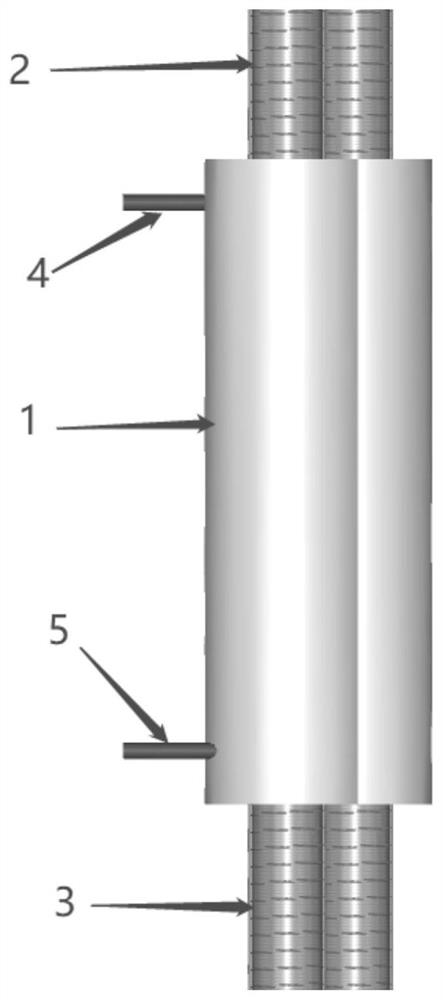

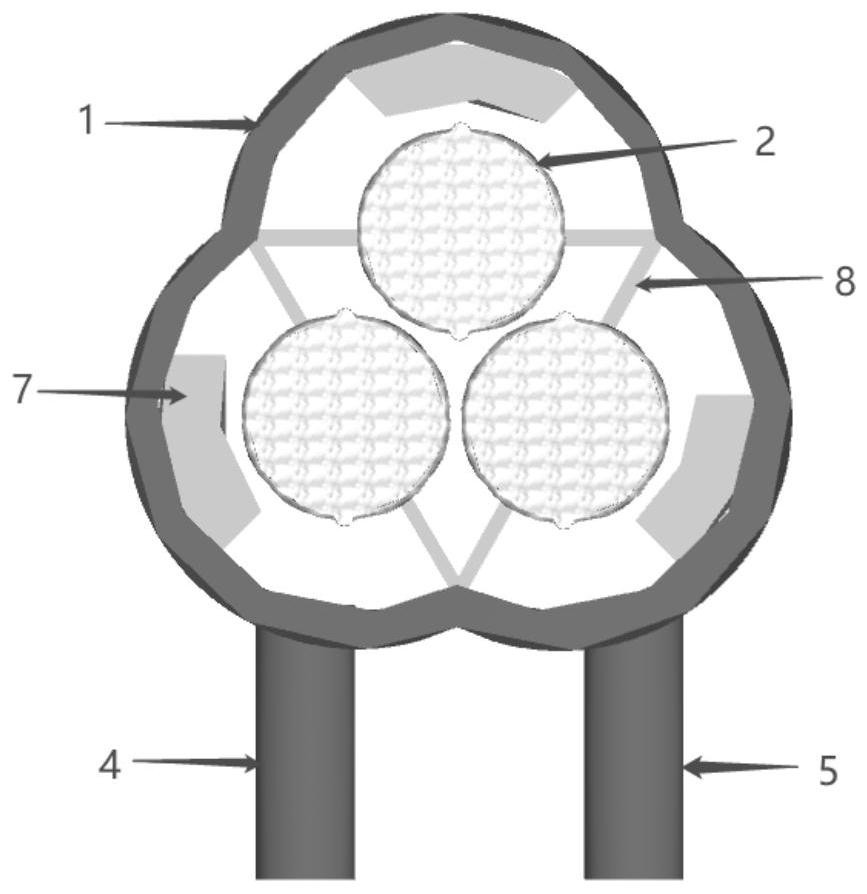

[0025] refer to Figure 1 to Figure 5 , the threaded grouting sleeve used for the glyph connection of three parallel ribs according to the present invention includes a sleeve body 1, the sleeve body 1 is a hollow structure, an upper sealing plug 6 is arranged at the top opening of the sleeve body 1, and the sleeve The bottom opening of the body 1 is provided with a lower sealing plug, the side of the bottom of the sleeve body 1 is provided with a grouting hole 5, the side of the top of the sleeve body 1 is provided with a grouting hole 4, and the inside of the sleeve body 1 is provided with a limit barrier 8 , wherein, the lower end of each upper steel bar 2 passes through the upper sealing plug 6 and is inserted into the sleeve body 1 and then contacts with the limit barrier 8, and the upper end of each lower steel bar 3 passes through the lower sealing plug and is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com