Axle box built-in bogie based on novel motor suspension structure and flexible interconnection framework

A flexible interconnection and bogie technology, which is applied to the transmission device, bogie, axle box and other directions driven by electric motors, can solve the problems of increasing the structural size and turning radius of the bogie, occupying space, and being unable to maintain, etc., to achieve convenience The effect of independent replacement and maintenance, reduction of occupation time, and improvement of turnover efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described in detail below with reference to the accompanying drawings.

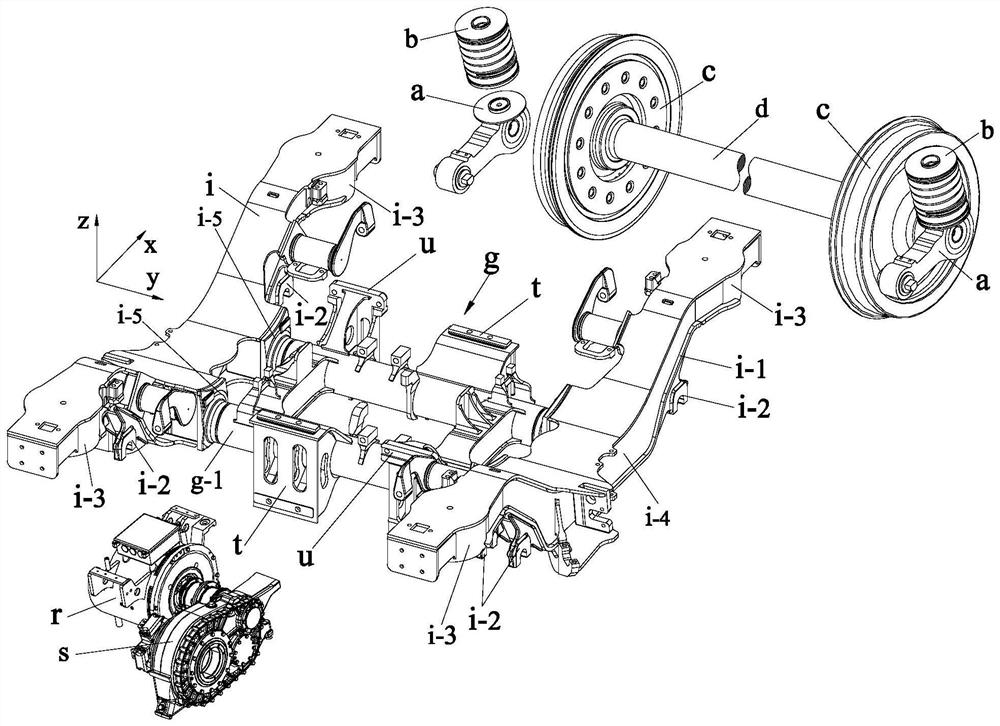

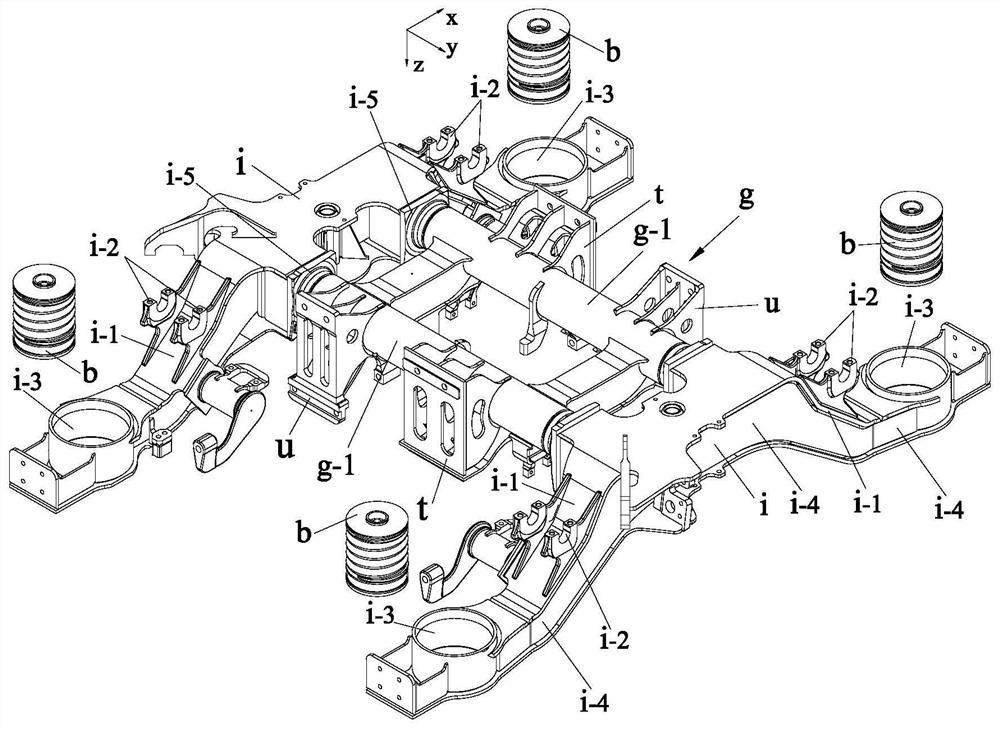

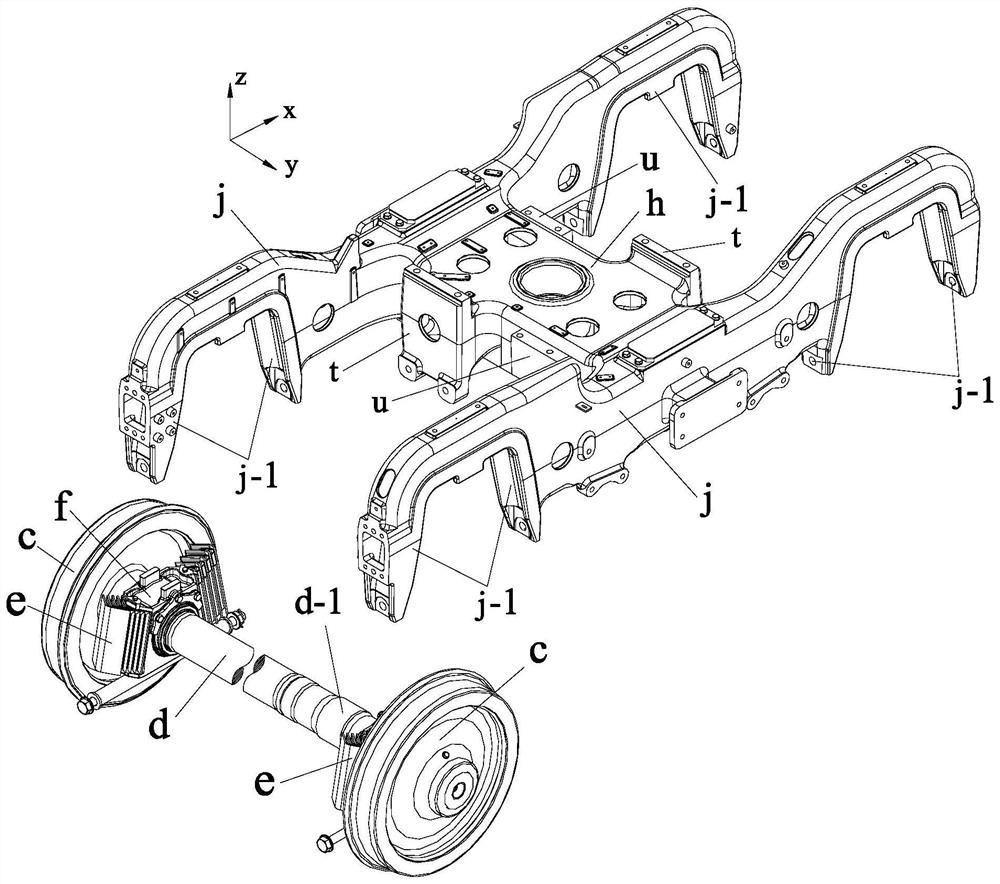

[0075] Such as Figure 7 to 26 As shown, the present invention has an axle box built-in steering frame based on a new motor suspension structure and a flexible interconnect frame comprising a wheel pair of wheel and axle, a cross-sectional flexible interconnect frame, four annular damping shafts Box, easy retractable gearbox and side beam single-point hanging motor;

[0076] The cross sectional flexible interconnect structure includes two cross-sectional integrated structures that are rotationally symmetrical, each of which includes integrated integrated side beams 1-1 and integrated beams 1-2; integrated The type side beam 1-1 includes two bird wing connecting portions and the lateral beams of the side beams from the lower position and two symmetrical solids in the middle end of the side beams 1-1-1. Section 1-1-2, the bird wing side beam cantilever section 1-1-2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com