Transverse slab-outputting method of CRTSII rail slab and slab field

A track slab and track technology, which is applied in the field of CRTS Ⅱ type track slab horizontal delivery and the field of slabs, can solve the problems that the longitudinal delivery cannot be adopted, and the number of slabs stored in the rough slab storage area cannot be guaranteed, so as to reduce the requirements and improve the output of the slab. speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

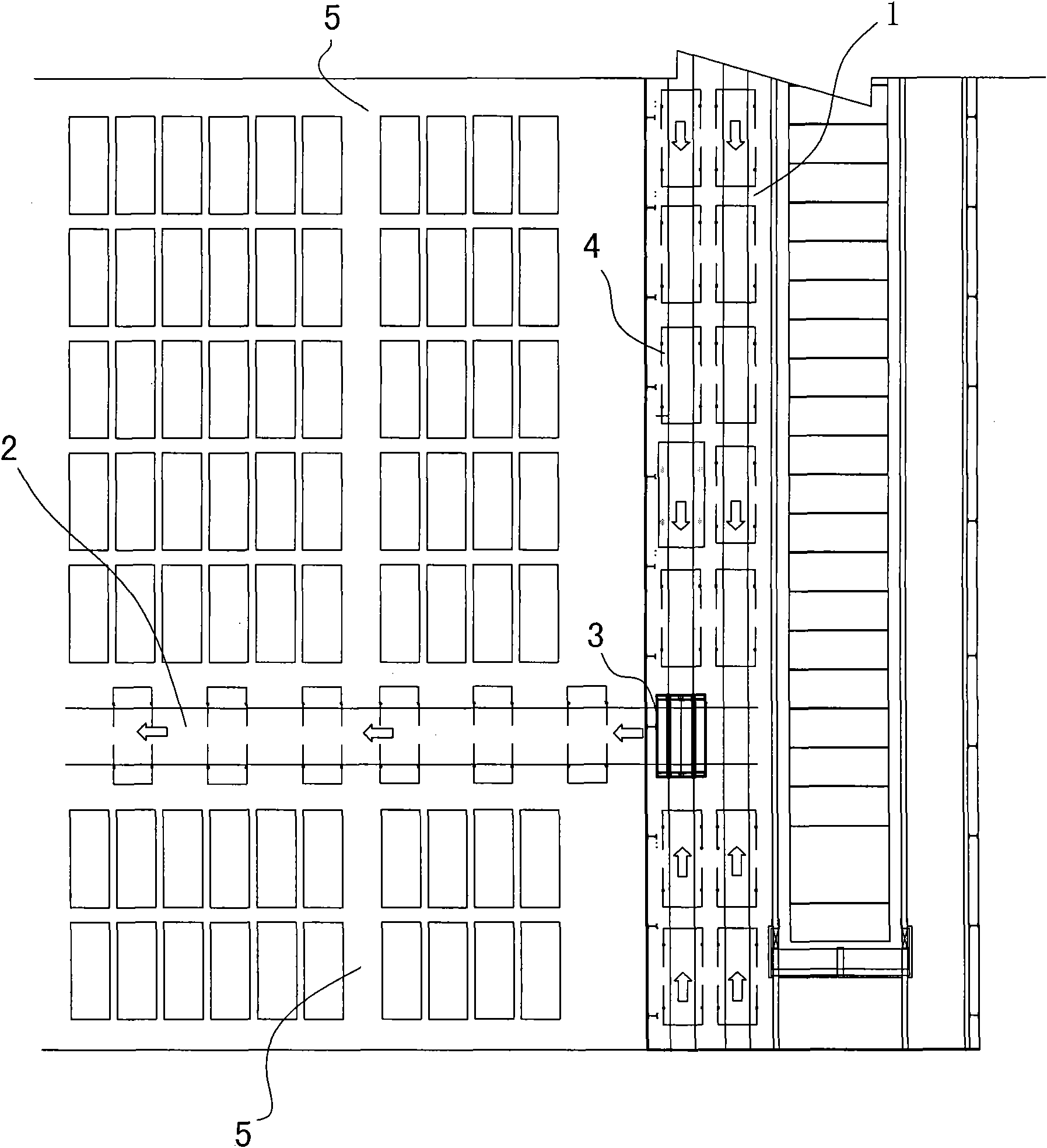

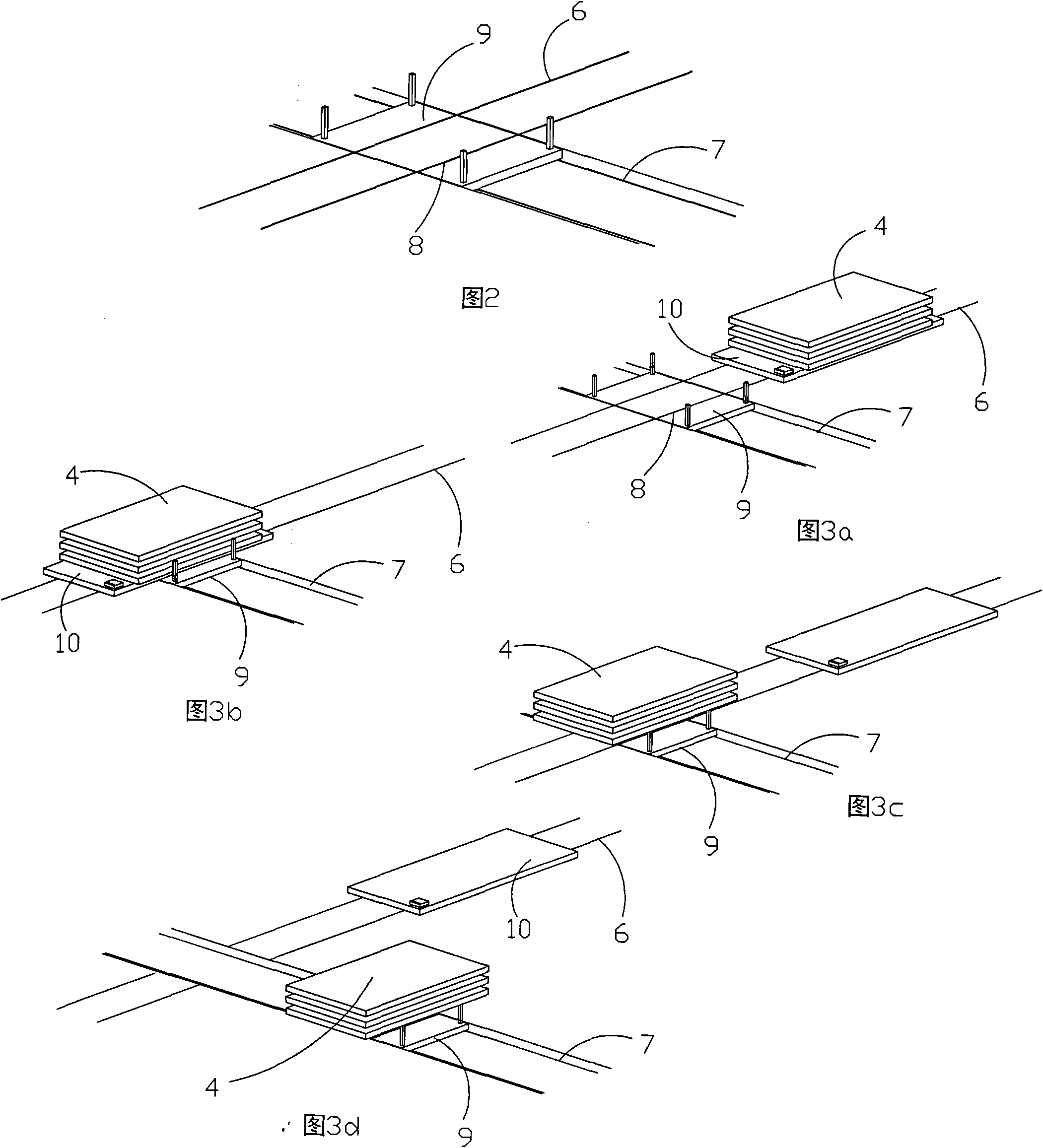

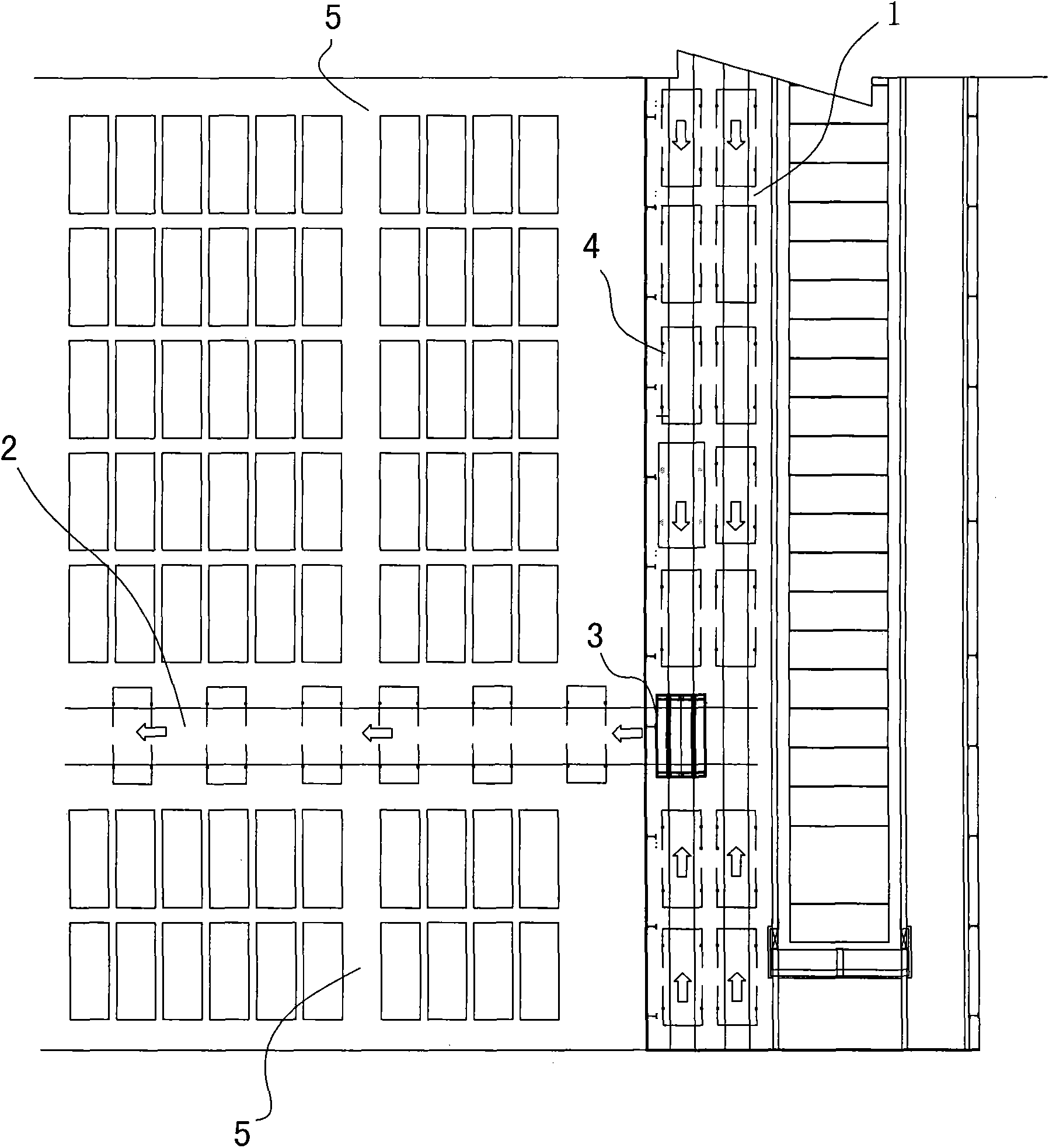

[0015] see figure 1 , figure 2 In this embodiment, the method for horizontally releasing the CRTS II track slab is to set a "T"-shaped board-out route composed of a longitudinal line 1 and a transverse line 2 perpendicular to the longitudinal line 1 and intersecting with the transfer crossing 3 to complete the prefabrication The rough board 4 is first transported to the transfer crossing 3 on the longitudinal line 1 by the board-out vehicle, and then transferred to the horizontal line 2 by the transfer crossing 3; the rough board storage area 5 is located on the left and right sides of the horizontal line 2, and the rough board 4. After being transported on the horizontal line 2 by the unloading car, the rough plate on the unloading car is unloaded by the crane in the rough plate storage area 5 located on the left and right sides of the horizontal line 2, and the plate out is completed.

[0016] In the present embodiment, the structure of the CRTS II type track slab horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com