Axle box built-in subway bogie based on flexible interconnection framework and upper swing bolster

A flexible interconnection and bogie technology, which is applied to bogies, devices that move laterally between the chassis and the bogies, axle boxes, etc., can solve the cumbersome process, increase the risk of damage to the axle box, and the unsatisfactory layout scheme Issues such as installation location and vibration reduction indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The present invention will be described in further detail below in conjunction with the accompanying drawings.

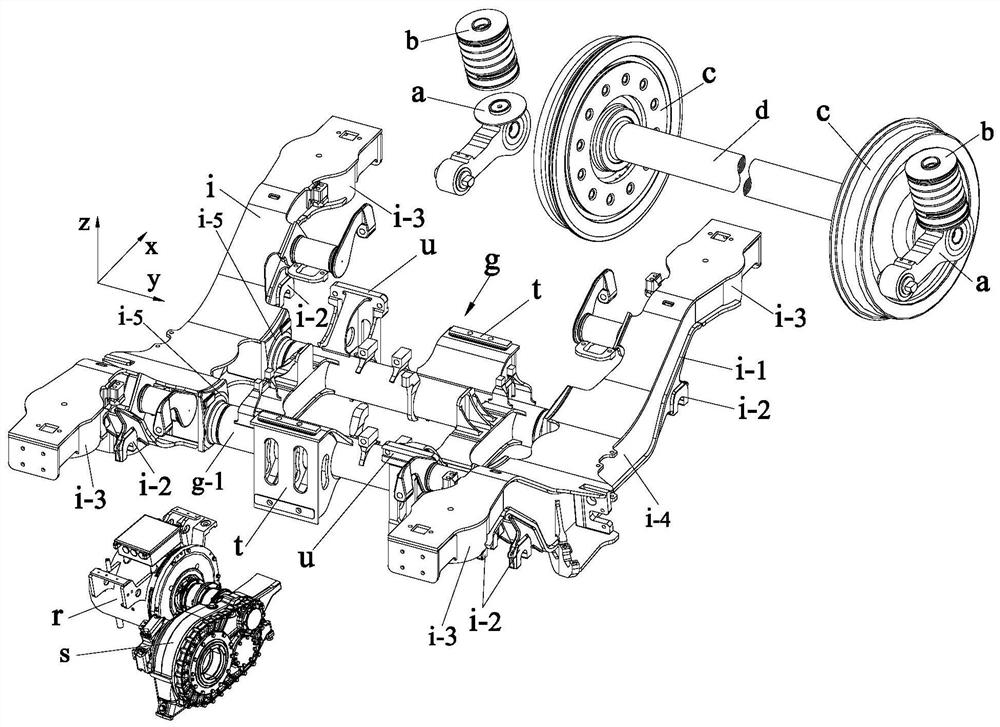

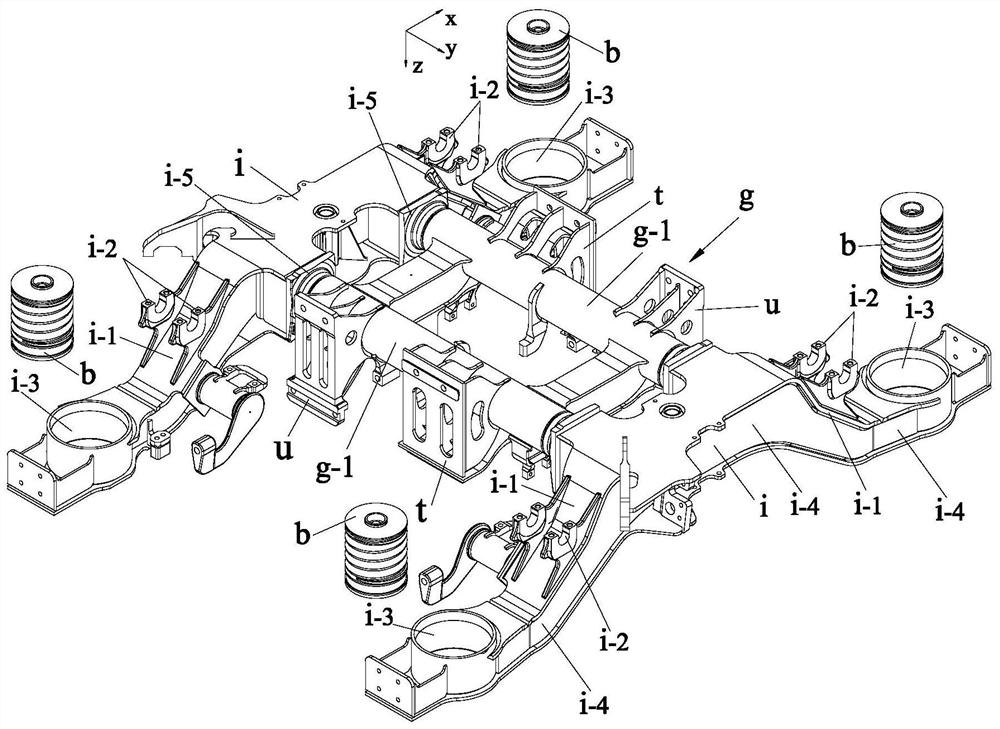

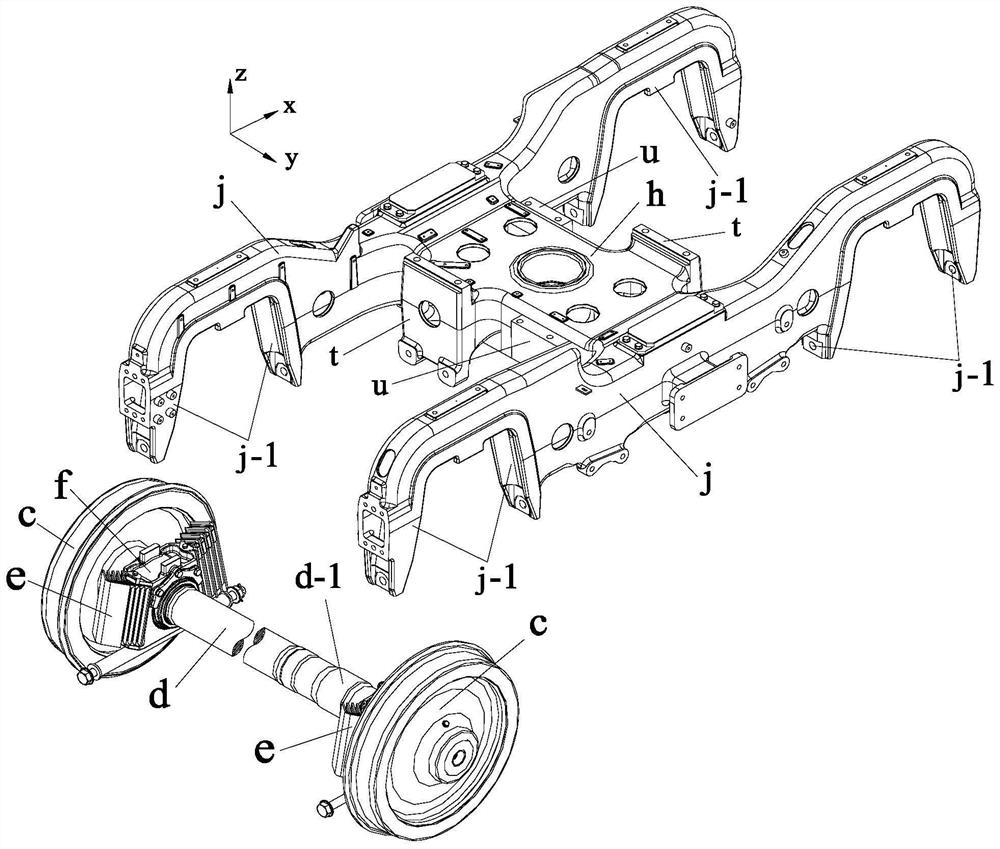

[0085] Such as Figure 10 to Figure 31 As shown, the axle box built-in subway bogie based on the flexible interconnection frame and the upper bolster of the present invention includes a wheel set device composed of a wheel c and an axle d, and the bogie also includes a horizontal and vertical integrated flexible interconnection Connecting frame A, four ring-shaped vibration-absorbing axle boxes B, easy-to-retract shaft gearbox D, side beam single-point suspension motor E, integrated vibration-absorbing bolster and secondary suspension system F;

[0086] Horizontally and vertically integrated flexible interconnection frame A includes two mutually rotationally symmetrical horizontally and vertically integrated frames, and each horizontally and vertically integrated frame includes integrally formed integrated side beams A-1 and integrated beams A-2; The integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com