Extrusion die for solid foaming plate with co-extrusion reinforced material

A technology of reinforcing materials and extruding molds, which is applied in the field of floor manufacturing, can solve problems such as production stagnation, high maintenance difficulty, channel blockage, etc., and achieve the effect of uniform thickness, high physical strength, and uniform surface layer feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

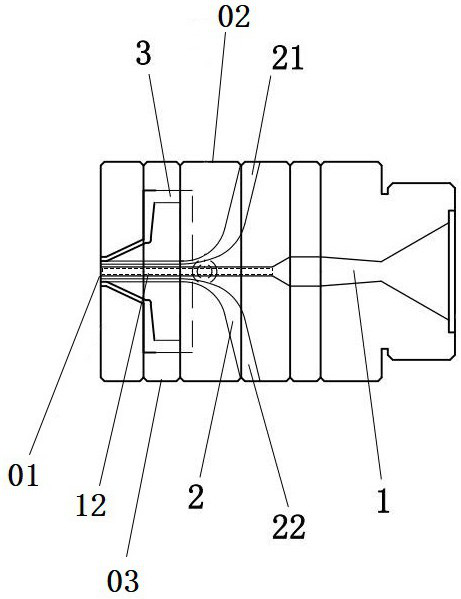

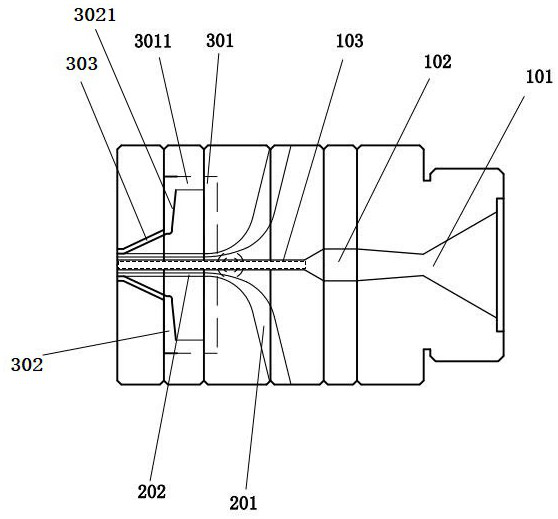

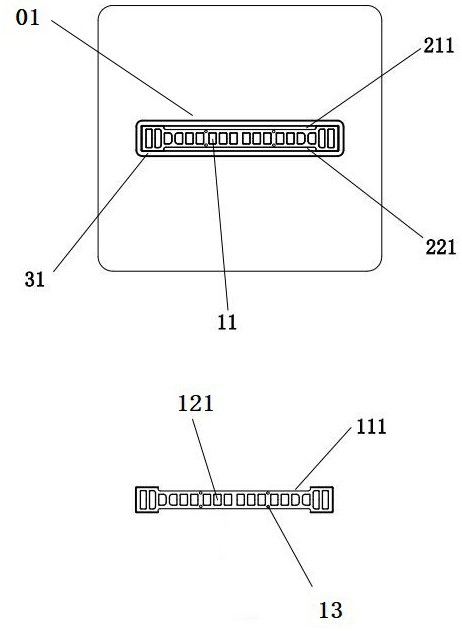

[0033] Such as Figure 1~Figure 4 As shown, a solid foam board extrusion die with co-extruded reinforcing materials is assembled from six mold plates, and the six mold plates from right to left are named plates 1 to 6, of which plate 4 is the mold The first flow channel forms plate 02, and plate five is the second flow channel forming plate 03 of the mould.

[0034] The mold has an axis in the horizontal direction, and the sprue 1 runs through six mold plates along the axis from right to left. The main channel 1 has a three-section structure of a pressurizing section 101, a steady flow section 102, and a discharge section 103; the pressurizing section 101 is located on the plate 1, and one end communicates with the outside of the mold for connecting the core material extruder, and the pressurizing section The diameter of the pipe first converges from large to small along the discharge direction. After converging to a certain size, the pipe diameter gradually increases and exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com