High-temperature alloy complex thin-wall part fluid medium forming die and high-temperature alloy complex thin-wall part fluid medium multi-pass forming method

A fluid medium and forming die technology, applied in the field of fluid medium forming die and multi-pass forming of complex thin-walled superalloy parts, can solve the problems of increasing manufacturing difficulty, uneven structure, forming and manufacturing difficulty, etc., and reduce deformation resistance. and equipment tonnage, improve the plastic deformation ability of materials, high film degree and high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

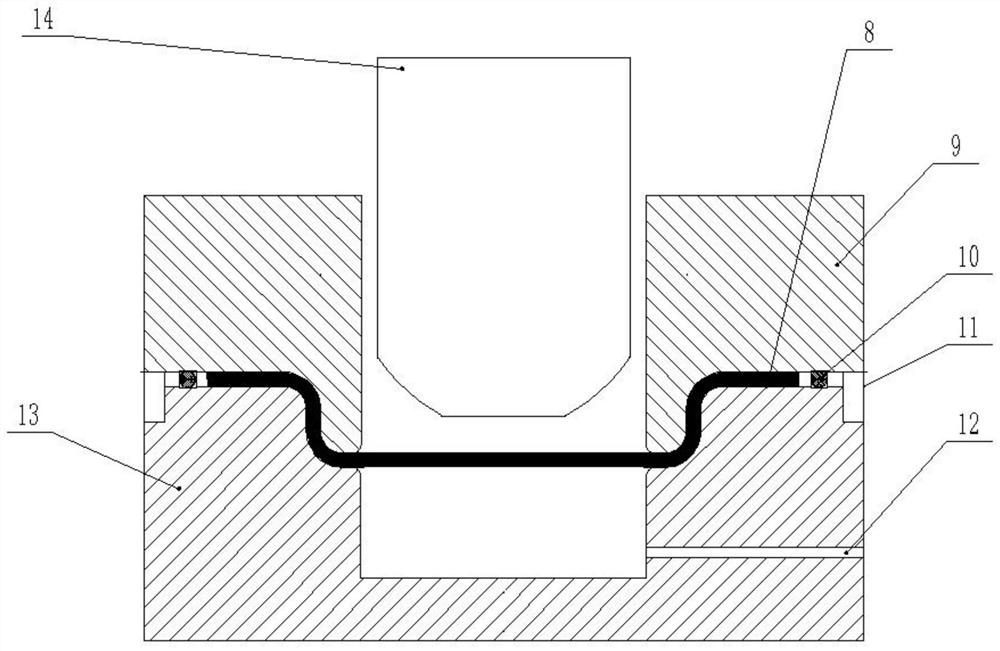

[0054] The following is based on Figure 1-6 Describe in detail a typical deep cone shape forming process formed by a fluid medium multi-pass forming method for complex thin-walled superalloy parts in a specific embodiment of the present invention, including the following steps:

[0055] 1) According to the shape of the final part, design the structure of the first pass transitional forming die, and obtain the diameter and forming height of the punch in the first pass transitional forming die; design the initial blank 7 according to the structure of the first pass transitional forming die;

[0056] 2) Clean the surface of each part before the assembly of the transition forming mold in the first pass to ensure the surface quality of the product and the service life of the mold equipment;

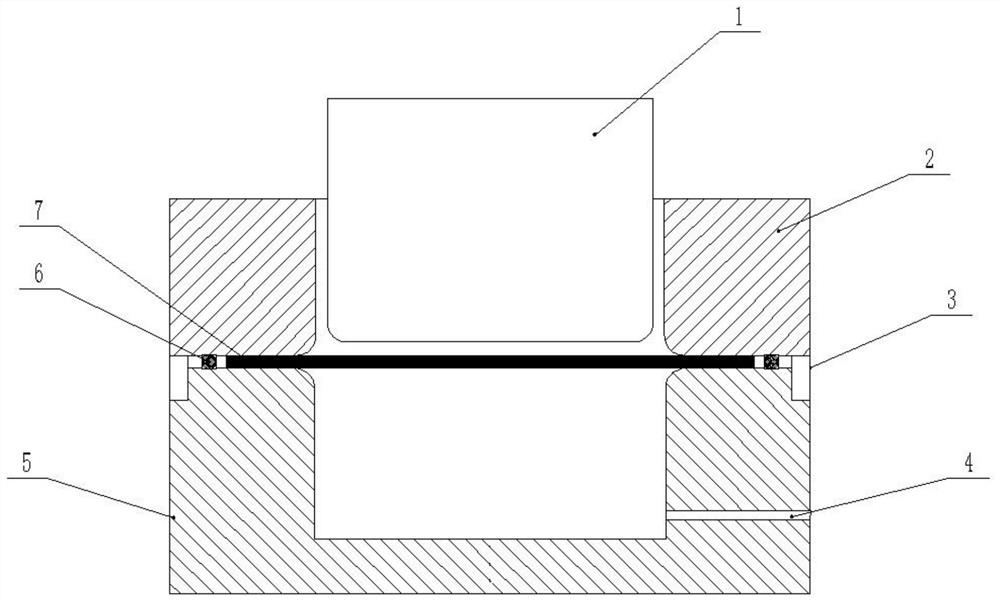

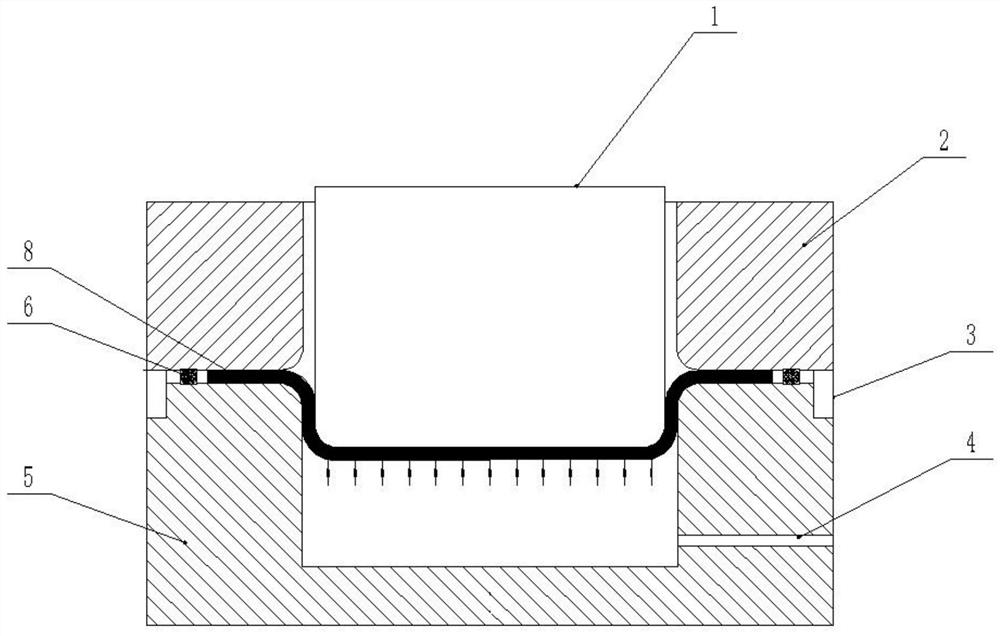

[0057] 3) if figure 1 As shown, the first pass transition forming mold is assembled, and the first pass transition forming mold is installed on the fluid medium forming equipment for debuggi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com