All-inorganic perovskite solar cell and preparation method thereof

A technology of solar cells and inorganic calcium, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low photoelectric conversion performance, poor carrier transport efficiency of solar cells, etc., to overcome poor thermal stability and be beneficial to industrial Production and practical application, the effect of improving the collection capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

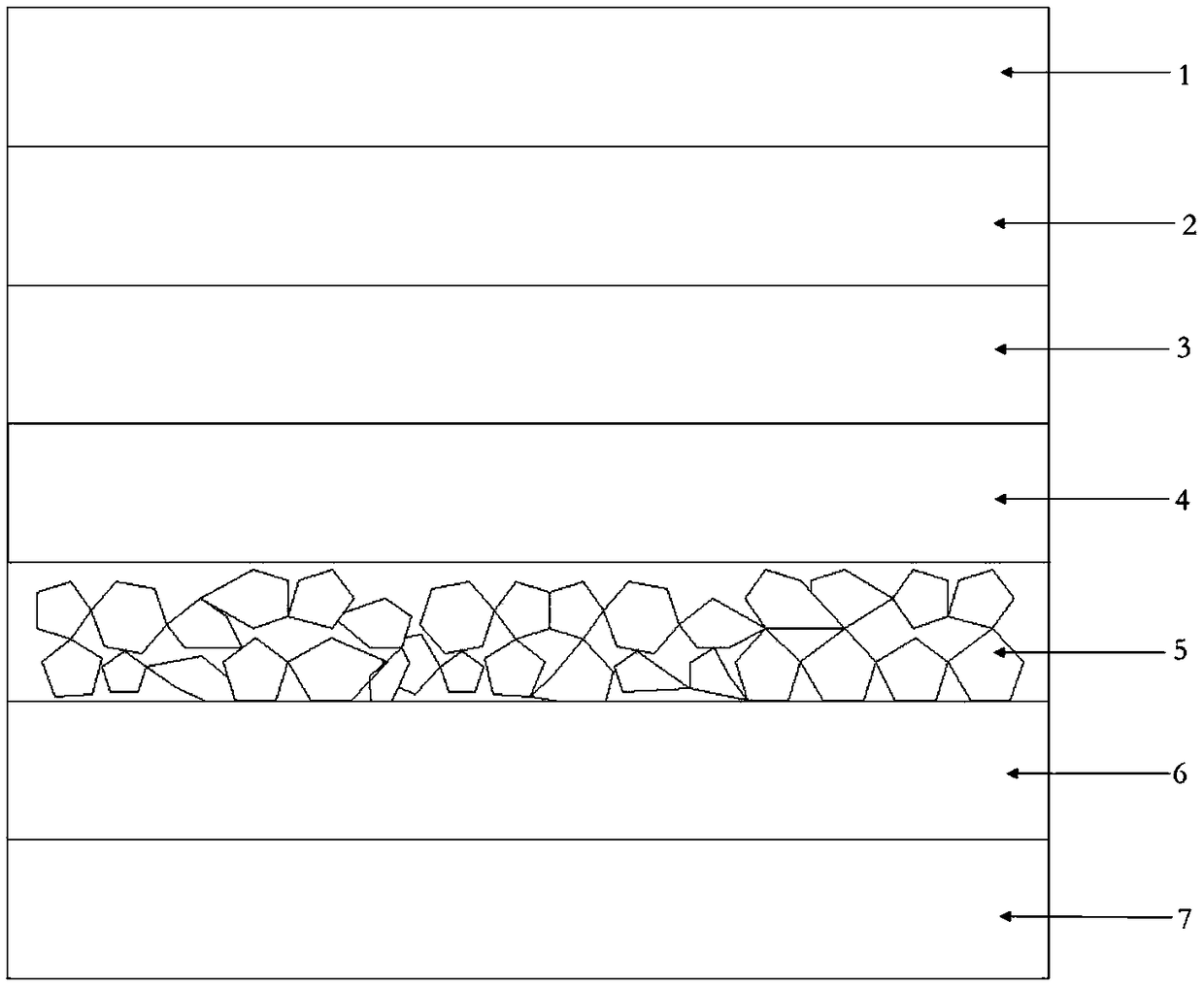

[0042] Such as figure 1 As shown, an all-inorganic perovskite solar cell, the solar cell includes a conductive glass layer, a dense hole transport layer, a mesoporous hole transport layer, an inorganic perovskite light-absorbing layer, and an electron transport layer from bottom to top. hole blocking layer and counter electrode layer.

[0043] Such as figure 2 Shown, the preparation method of above-mentioned perovskite solar cell comprises the following steps:

[0044] (1) Preparation of dense hole transport layer: on the FTO conductive glass layer, a NiO dense hole transport layer with a thickness of about 8 nm was prepared by electron beam evaporation;

[0045] (2) Preparation of mesoporous hole transport layer: the mesoporous hole conductor material CuGaO 2 (mp-CuGaO 2 ) was dissolved in isopropanol and ethyl cellulose and terpineol were added to prepare a slurry, which was spin-coated on the dense hole transport layer at 5000rpm for 30 seconds, and a dielectric layer ...

Embodiment 2

[0052] An all-inorganic perovskite solar cell, the solar cell comprises a conductive glass layer, a dense hole transport layer, a mesoporous hole transport layer, an inorganic perovskite light-absorbing layer, an electron transport layer, and a hole blocking layer from bottom to top. layer and the counter electrode layer.

[0053] The preparation method of above-mentioned perovskite solar cell comprises the following steps:

[0054] (1) Preparation of a dense hole transport layer: a CuO dense hole transport layer with a thickness of 10 nm was prepared on the FTO conductive glass layer by electron beam evaporation;

[0055] (2) Preparation of mesoporous hole transport layer: the mesoporous hole conductor material CuCrO 2 Dissolve in isopropanol and add ethyl cellulose and terpineol to prepare a slurry, spin-coat it on the dense hole transport layer at 5000rpm for 30 seconds, and obtain a mesoporous hole with a thickness of 150nm after annealing at 300°C. Cave transport layer;...

Embodiment 3

[0062] A perovskite solar cell of an all-inorganic hole transport material, the solar cell sequentially includes a conductive glass layer, a dense hole transport layer, a mesoporous hole transport layer, an inorganic perovskite light-absorbing layer, and an electron transport layer from bottom to top. layer, hole blocking layer and counter electrode layer.

[0063] The preparation method of above-mentioned perovskite solar cell comprises the following steps:

[0064] (1) Preparation of a dense hole transport layer: a CuI dense hole transport layer with a thickness of 10 nm was prepared by electron beam evaporation on the FTO conductive glass layer;

[0065] (2) Preparation of mesoporous hole transport layer: the mesoporous hole conductor material CuAlO 2 Dissolve in isopropanol and add ethyl cellulose and terpineol to prepare a slurry, spin-coat it on the dense hole transport layer at 5000rpm for 30 seconds, and obtain a mesoporous hole with a thickness of 150nm after anneali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com