Bag type solid-liquid separation device and solid-liquid separation method

A solid-liquid separation and bag-type technology, applied in the direction of separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of small solid-liquid treatment capacity, increased liquid content of solid materials, hidden dangers of human body and environment safety, etc., to achieve Avoid backwashing process, low moisture content, full detachment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

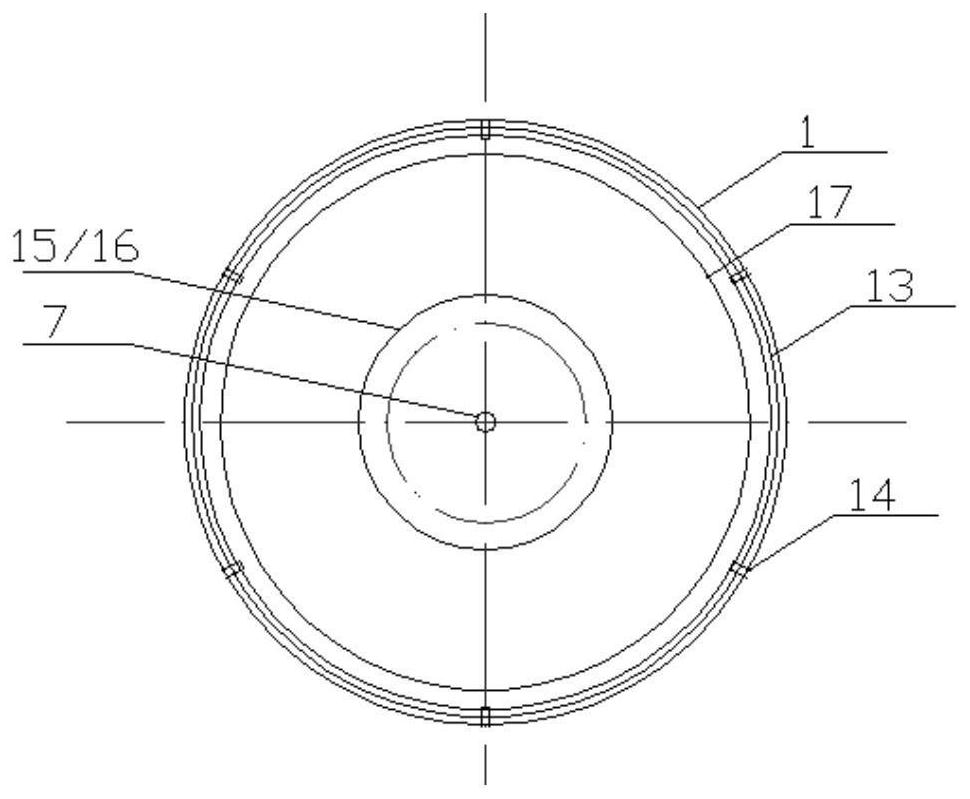

[0058] The material is an organic solvent system containing amorphous flocculent wax, with a wax content of 8%. The mixture enters the bag mechanism 5 of the upper cylinder 1 through the feed port 10, and the filtrate is discharged from the filtrate outlet 11. After processing 20kg of the mixture, when the pressure of the feed port 10 reaches the set value of 0.5 MPa, the feed port 10 is completely closed, and the residual material discharge port 12 is opened for 10 seconds. After the residual material is completely discharged, the residual liquid discharge port 12 is closed; the gate valve 3 is fully opened, the hydraulic drive motor 4 runs, the transmission rod 7 pushes the upper part of the cloth bag 17 to move down, and the solid material starts to fall off from the cloth bag 17 and is discharged from the discharge port 6. When the transmission rod 7 reaches the maximum stroke, the cloth bag 17 is completely reversed, most of the solid materials fall off from the cloth bag ...

Embodiment 2

[0060] The material is a mixture of coal slime and water with a solid content of 5%, and the particle size distribution is shown in Table 1. The mixture enters the bagging mechanism 5 of the upper cylinder 1 through the feed port 10, and the filtrate is discharged from the filtrate outlet 11. After processing 100kg of coal slime water, when the pressure of the feed port 10 reaches the set value of 0.2MPa, the feed port 10 is completely closed, and the residual material discharge port 12 is opened for 10 seconds. After the residual material is completely discharged, the residual liquid discharge port 12 is closed; The valve 3 is fully opened, the hydraulic drive motor 4 runs, the transmission rod 7 pushes the upper part of the cloth bag 17 to move down, and the pulverized coal begins to fall off from the cloth bag 17 and is discharged from the discharge port 6. When the transmission rod 7 reaches the maximum stroke, the cloth bag 17 is completely reversed, most of the pulverized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com