Sweetening agent for improving flavor and taste of rubusoside and preparation method of sweetening agent

A technology of rubusoside and sweeteners, applied in the field of sweeteners and preparations to improve the sweetness of rubusoside, which can solve the problems of incomplete removal steps or desalination, serious sweetness, and post-sedimentation phenomenon, so as to improve the taste Taste, sweetness improvement, sweetness refreshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

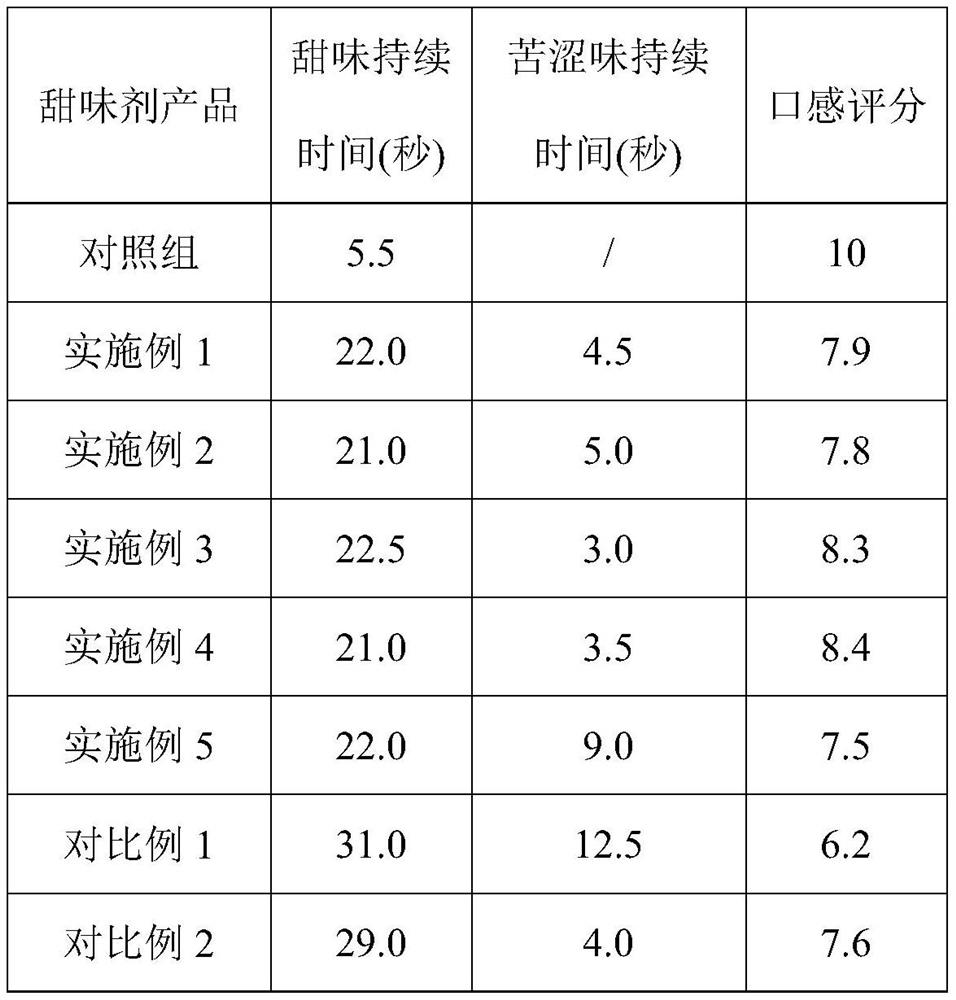

Examples

preparation example 1

[0061] The cross-linking modification of preparation example 1 LX-17 resin

[0062] Add 1kg of LX-17 resin, 3.5L of BCMB, and 12L of carbon tetrachloride into a stirring reactor, let it swell for 10 hours, add 0.2kg of anhydrous zinc chloride, and react for 12 hours under stirring at 60°C. After the reaction, wash with absolute ethanol and deionized water until no precipitation occurs after adding the nitrate solution to obtain chloromethylated LX-17 resin. Chloromethylated LX-17 resin was added to 12L dimethyl sulfoxide after dehydration to swell for 8h, slowly added 0.3kg of anhydrous aluminum chloride and 0.05kg of 1,4-cyclohexanediamine, and heated to 50 React for 12 hours under stirring condition at ℃, filter, wash with absolute ethanol and deionized water respectively, until no precipitation occurs after adding nitrate solution, place the obtained resin in a blower dryer, and dry in vacuum at 60°C overnight to obtain a cross-linked modified resin. Resistant LX-17 resin....

preparation example 2

[0064] Preparation example 2 Cross-linking modification of DA-201 resin

[0065] Add 1kg of DA-201 resin, 3.5L of BCMB, and 12L of carbon tetrachloride into a stirred reactor, let it swell for 10 hours, add 0.2kg of anhydrous zinc chloride, and react for 12 hours under stirring at 60°C. After the reaction, wash with absolute ethanol and deionized water until no precipitation occurs after adding the nitrate solution to obtain chloromethylated DA-201 resin. Add the chloromethylated DA-201 resin to 12L dimethyl sulfoxide after dehydration to swell for 6 hours, slowly add 0.3kg of anhydrous aluminum chloride and 0.08kg of triethylenetetramine, and raise the temperature to 50°C under the condition of stirring React for 10 hours, filter, wash with absolute ethanol and deionized water respectively, until no precipitation occurs after adding nitrate solution, put the obtained resin in a blower dryer, and dry it under vacuum at 60°C overnight to obtain cross-linked modified DA- 201 re...

Embodiment 1

[0068] (1) Decolorization: 80 kg of LXD-200 resin is preliminarily installed in a stainless steel chromatography column and treated with ethanol, 4% aqueous sodium hydroxide solution, and 4% hydrochloric acid according to the standard procedure for regeneration of macroporous adsorption resin for use. Take 10kg of 70% rubusoside powder, add 170L of purified water, stir to dissolve, then pass the solution through a chromatography column equipped with LXD-200 resin, and collect the feed effluent; after feeding the material, enter 160L of purified water to wash the resin column , to collect the washing solution. Combine the feed effluent and washing liquid to obtain 320L decolorized liquid.

[0069] (2) Acid-removing phenol: 10 kg of LX-17 resin is preliminarily installed in a stainless steel chromatography column and treated with ethanol, 4% aqueous sodium hydroxide solution, and 4% hydrochloric acid according to the standard procedure for regeneration of macroporous adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com