A compound sweetener for improving rubusoside taste and preparation method thereof

A compound sweetener and rubusoside technology, which is applied in food ingredients containing non-sugar sweeteners, food ingredients as taste improvers, food science, etc., can solve the problem of limiting the application range of natural high-sweetness sweeteners, difficult Eliminate the problems of bitterness and astringency, the disappearance of bitterness and astringency, and achieve the effects of maintaining stability and excellent performance, improving bitterness and long-lasting sweetness, and increasing fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

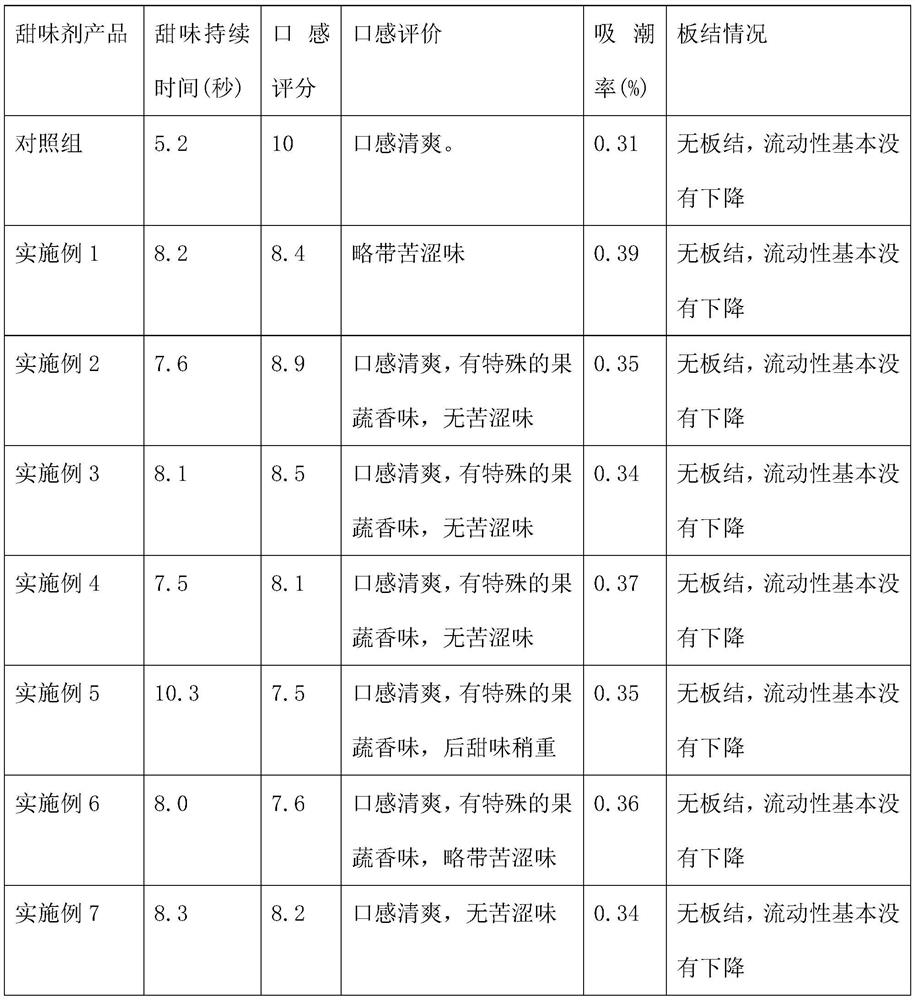

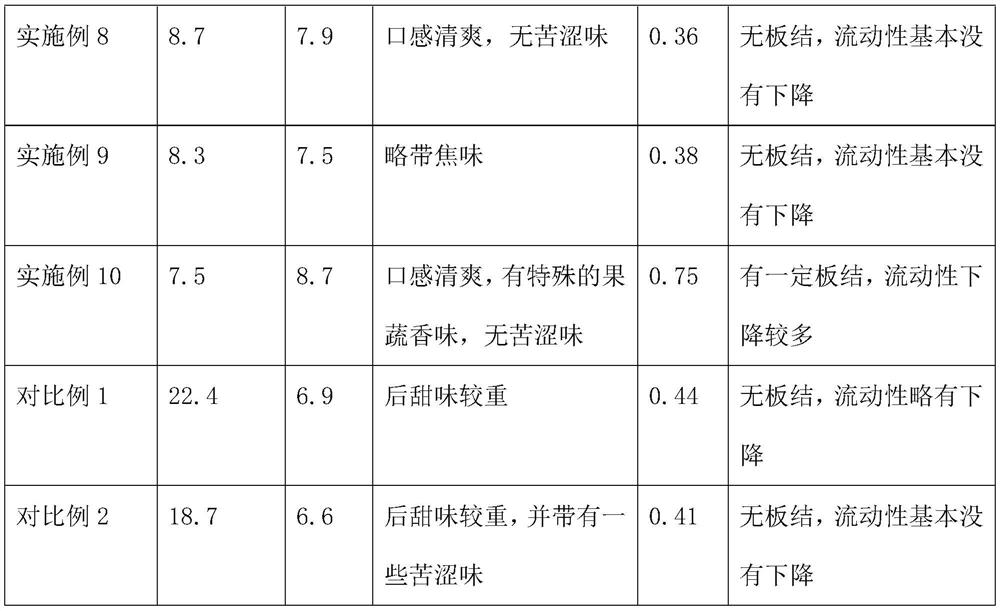

Examples

Embodiment 1

[0109] This embodiment includes the following steps:

[0110] (1) Preparation of okra mucus:

[0111] ①Extraction: Take 100kg of young okra fruit, break it into long thin pieces with a width of about 5mm with a medicine cutter, and put it into 1m 3 In a stirring tank, use water as a solvent, and extract with stirring at a room temperature of 17°C. Extract 2 times, add 600L of water for the first time, extract for 2.0h; add 500L of water for the second time, extract for 1.5h. After each extraction and filtration, the residue of the first extraction is then extracted for the second time. Combine the first and second extracts to obtain 1100L of water extract; the extraction residue after the second extraction is collected in a separate device.

[0112] ② Clarification: First pass the water extract through a disc centrifuge, and then through a complete set of ceramic membrane equipment with a pore size of 500nm. After feeding the feed liquid, add 300L of purified water to wash...

Embodiment 2

[0128] (1) Preparation of okra mucus:

[0129] ①Extraction: Take 100kg of young okra fruit, break it into long thin pieces with a width of about 7mm with a medicine cutter, and put it into 1m 3 In a stirring tank, use water as a solvent, and extract with stirring at a room temperature of 26°C. Extract 2 times, add 600L of water for the first time, extract for 2.0h; add 500L of water for the second time, extract for 1.5h. After each extraction and filtration, the residue of the first extraction is then extracted for the second time. Combine the first and second extracts to obtain 1100L of water extract; the extraction residue after the second extraction is collected in a separate device.

[0130] ② Clarification: first pass the water extract through a disc centrifuge, and then through a complete set of ceramic membrane equipment with a pore size of 300nm. After feeding the feed liquid, add 300L of purified water to wash the upstream liquid of the ceramic membrane, and combin...

Embodiment 3

[0146] (1) Preparation of okra mucus:

[0147] ①Extraction: Take 100kg of young okra fruit, break it into long thin pieces with a width of about 4mm with a medicine cutter, and put it into 1m 3 In a stirring tank, use water as a solvent, and extract with stirring at a room temperature of 8°C. Extract 2 times, add 600L of water for the first time, extract for 2.0h; add 500L of water for the second time, extract for 1.5h. After each extraction and filtration, the residue of the first extraction is then extracted for the second time. Combine the first and second extracts to obtain 1100L of water extract; the extraction residue after the second extraction is collected in a separate device.

[0148]② Clarification: First pass the water extract through a disc centrifuge, and then through a complete set of ceramic membrane equipment with a pore size of 500nm. After feeding the feed liquid, add 300L of purified water to wash the upstream liquid of the ceramic membrane, and combine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com