Buoyancy resistance induction type water heater water level sensor

A water level sensor and inductive technology, which is applied in the direction of liquid level indicator for physical variable measurement, can solve problems such as collision, thermal shock of water level sensor, collision of water tank side wall, etc., and achieve the effect of accurate installation and reliable measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with examples, and it should be understood that these examples are only for illustrating the present invention and are not intended to limit the scope of the present invention.

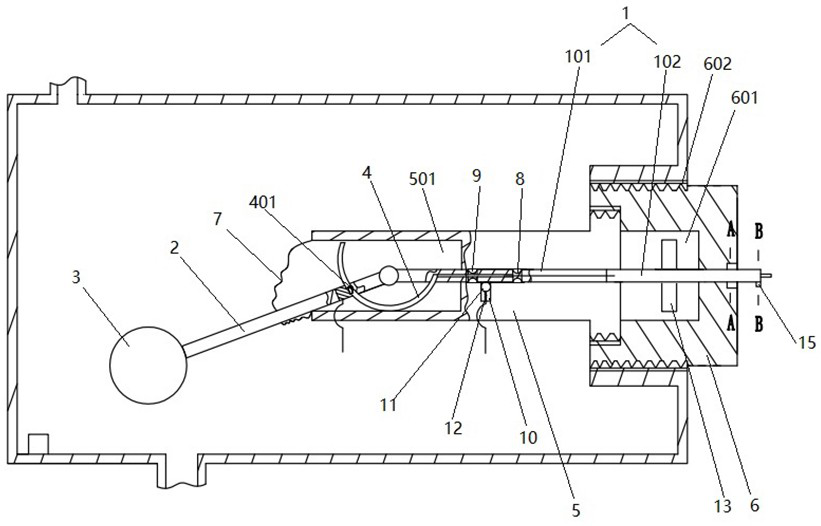

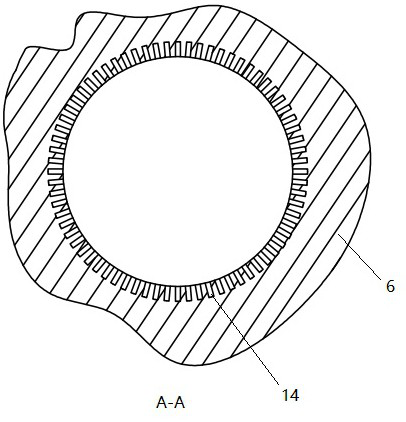

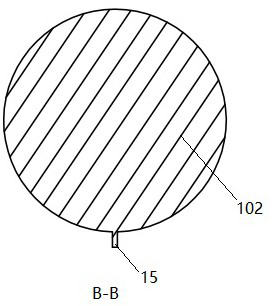

[0017] Please combine Figure 1 to Figure 3 As shown, the buoyancy resistance inductive water heater water level sensor involved in this embodiment includes a connection assembly, a skeleton rod 1 , a floating rod 2 , a floating ball 3 and an arc-shaped sliding rheostat 4 . The connection assembly includes a guide frame 5 and a connecting part 6. The guide frame 5 is T-shaped. The head of the guide frame 5 is provided with a concave cavity 501. The front end of the connecting part 6 is a limiting cavity 601. The tail of the guide frame 5 and the connecting part 6 The inner wall of the limiting cavity 601 is threaded. A connecting thread 602 is provided on the outer peripheral surface of the connecting part 6 , and the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com