A launch vehicle and cutting assembly for separation between launch vehicle stages

A carrier rocket and inter-stage separation technology, applied to offensive equipment, projectiles, self-propelled bombs, etc., can solve problems such as increased labor intensity and complex structure of cutting components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

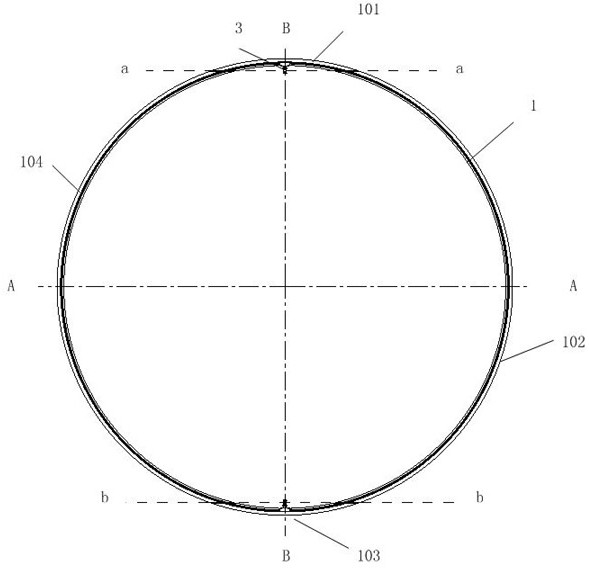

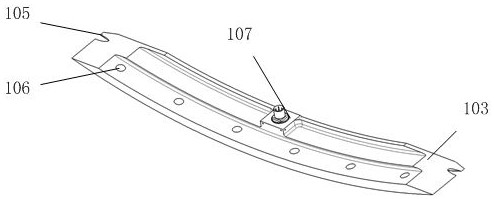

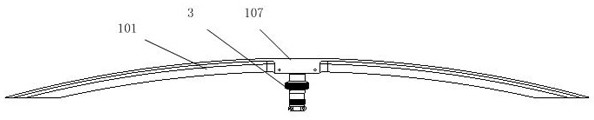

[0024] figure 1 The front view of the cutting assembly provided by the embodiment of the present invention; figure 2 and image 3 Schematic diagrams of the structure of the shroud ring segment with the detonator installed in the cutting assembly provided by the embodiment of the present invention; Figure 4 A cross-sectional view of the shroud ring segment with the detonator installed for the cutting assembly provided by the embodiment of the present invention; Figure 5 A schematic diagram of a cutting assembly provided with a reinforcing plate for an embodiment of the present invention.

[0025] Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a cutting assembly for interstage separation of a launch vehicle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com