Automatic glue attaching volume control device and method

An automatic control device and a glue-attached technology, which is applied in the field of chemical fiber spinning industry, can solve problems such as the inability to optimize and improve the dipping process, the inability to effectively monitor and adjust, and the inability to guarantee product quality, so as to achieve overall cost reduction. It is easy to control, beneficial to the occupational health of employees, and improves the effect of market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Obviously, the described embodiments are part of the embodiments of the present invention, not all of them. the embodiment.

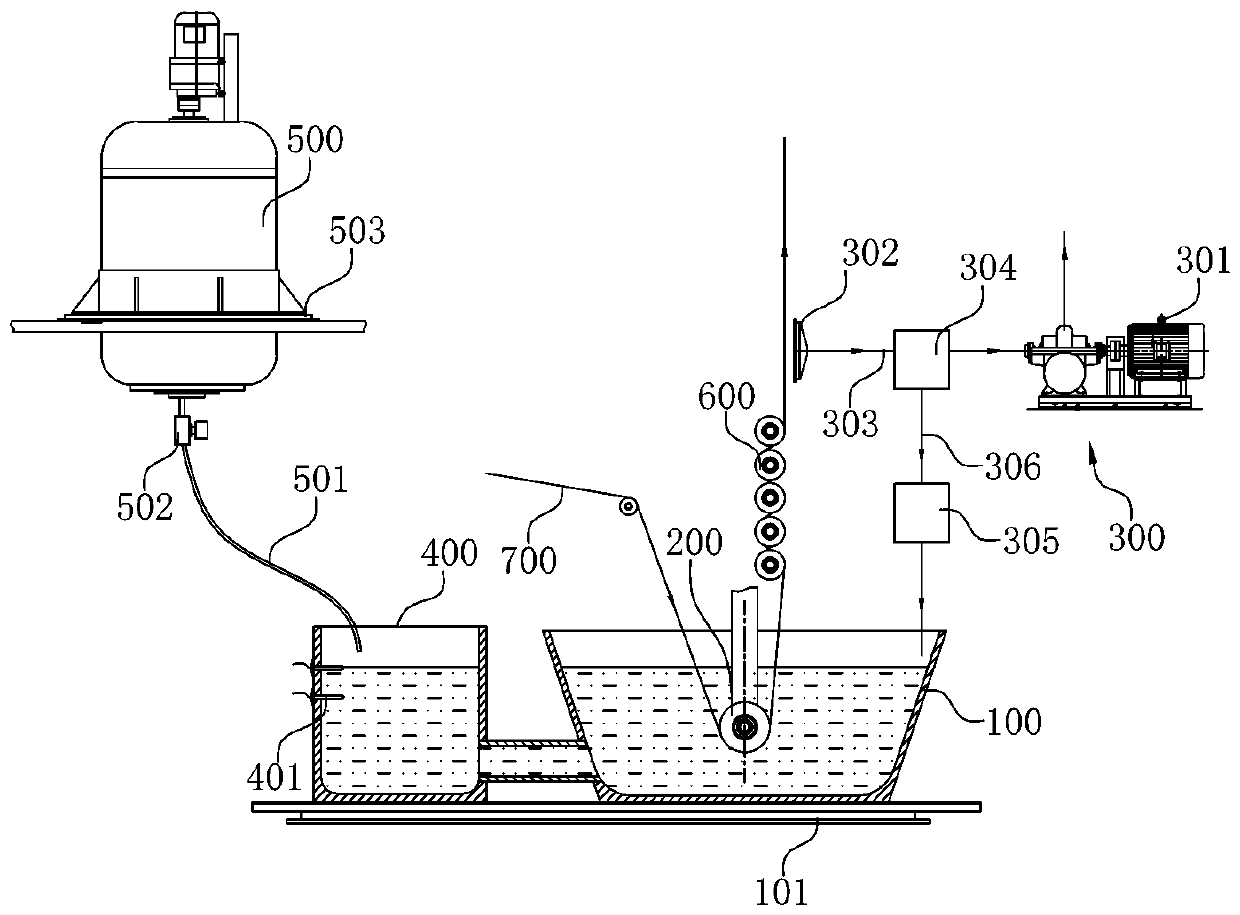

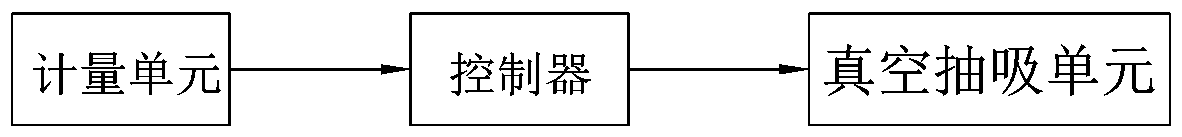

[0037] see figure 1 and figure 2 , the present invention discloses an automatic control device for the amount of glue attached, which is installed in the dipping part of the cord 700. The existing commonly used dipping part includes a dipping tank 100, a device set in the dipping tank 100 The dipping roller 200 and the vacuum suction unit 300 used to suck the excess dipping liquid on the dipped cord, that is, the cord 700 enters the dipping tank 100, and is turned and drawn out by the dipping roller 200, and the vacuum suction unit 300 realizes the suction of excess glue, and is usually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com