Roadbed structure based on polyurethane cured waste slurry material

A technology for waste mud and polyurethane, applied in infrastructure engineering, roads, roads, etc., can solve the problems of reducing the service life of subgrade structures, low road safety performance, poor firmness, etc., to improve the degree of lateral movement resistance and improve water stability. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

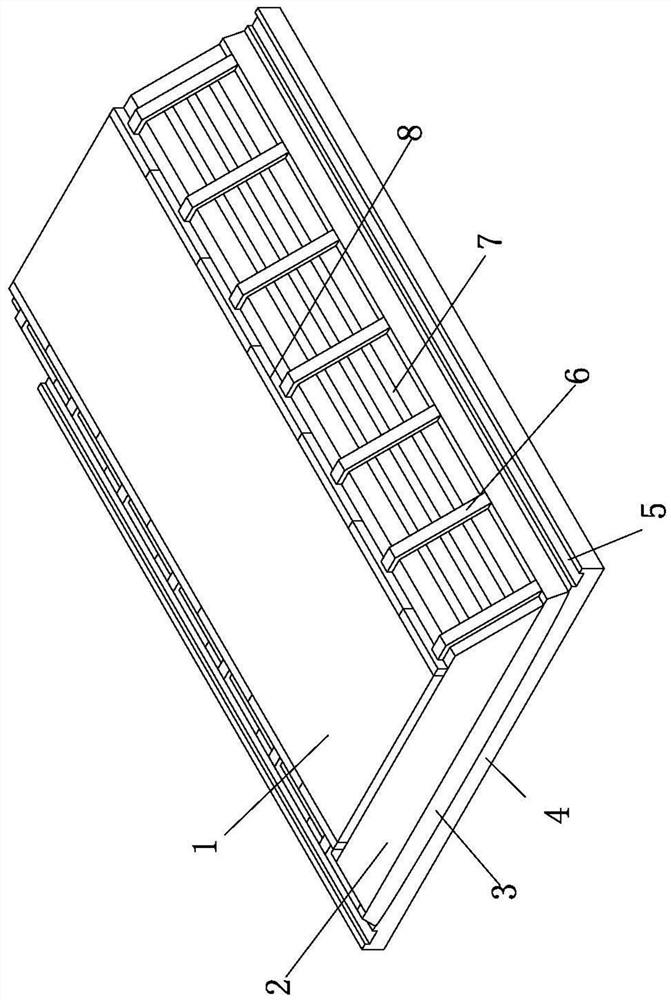

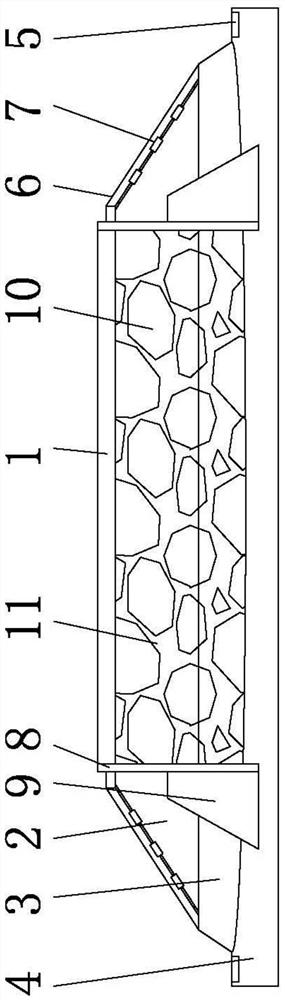

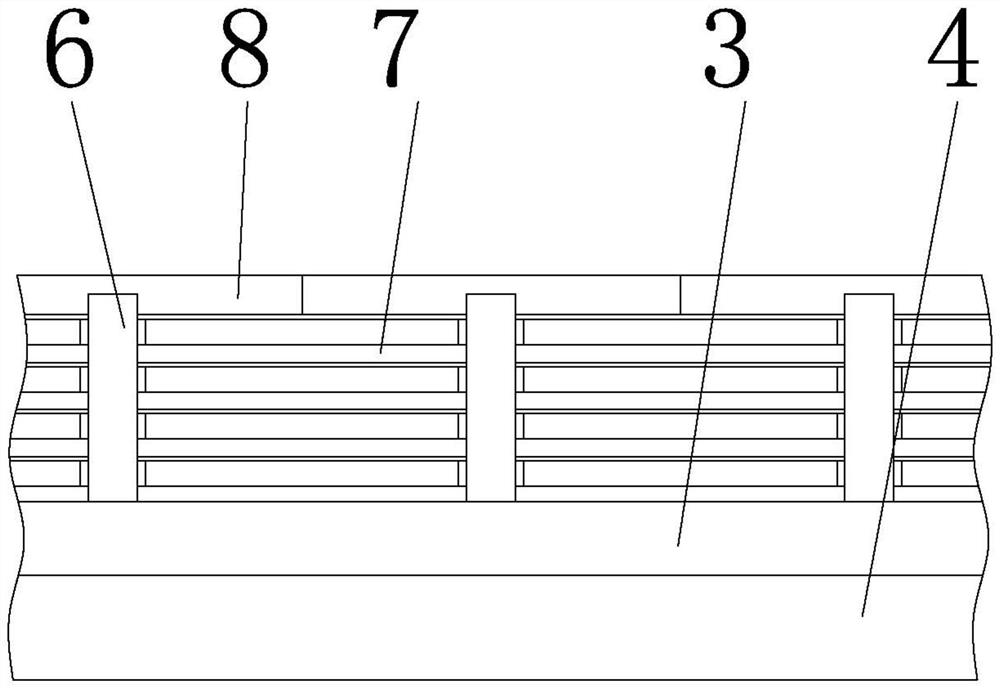

[0027] Please refer to the attached figure 1 to attach image 3 As shown, the present invention is a roadbed structure based on polyurethane solidified waste mud material, which includes a road bed 1, and an upper embankment 2, a lower embankment 3, and a foundation 4 are sequentially arranged below the road bed 1 from top to bottom. Stone slabs 8 are arranged symmetrically on both sides of the road bed 1 . The stone slabs 8 respectively penetrate the upper embankment 2 and the lower embankment 3 along the vertical direction. The bottom end of the stone slab 8 is embedded in the foundation 4 .

[0028] Wherein, stones 10 are arranged in the space enclosed by the road bed 1 , the foundation 4 and two stone slabs 8 . A trapezoidal block 9 is provided on the other side of the stone slab 8 relative to the stone 10 ; When the vehicle is running on the road, the gravity of the vehicle directly presses down on the stone 10, and the stone 10 presses down on the foundation 4. At th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com