Novel steel pipe cast-in-place pile and bearing capacity and internal force calculation method thereof

A calculation method and technology of cast-in-place piles, which are applied in sheet pile walls, complex mathematical operations, tests of foundation structures, etc., can solve problems such as large difference in service life of cast-in-place piles, poor corrosion resistance of steel structures, and unclear force distribution. Achieve the effect of optimizing the pile foundation section, strong resistance to horizontal load, and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

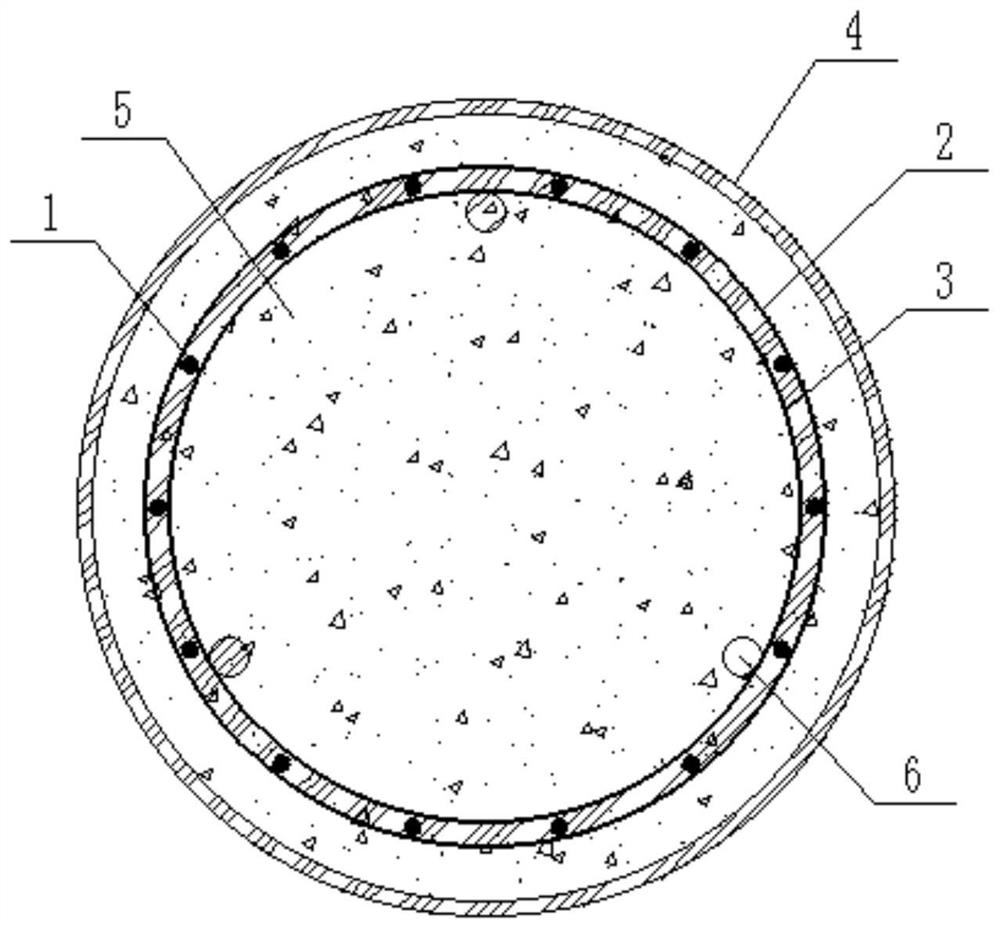

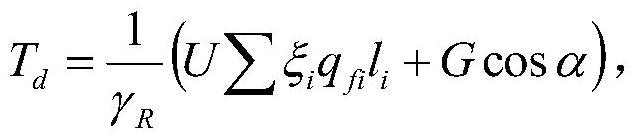

[0095] The water area of a wharf project uses cast-in-situ piles with a diameter of 1.2m. The depth of the pile foundation is 15m. The mud surface is about 6m, and the bending moment of the pile foundation reaches 1760kN.m.

[0096] In this case, 1.2m cast-in-place piles, C30 concrete, 21 HRB400 steel bars with a diameter of 25mm are required to be installed under working conditions, and a 20m long casing with a diameter of 1.4m and a wall thickness of 18mm is required. If steel pipe cast-in-place piles are used, only a 1m diameter C30 concrete pile core is required, with 18 HRB400 steel bars with a diameter of 25mm, and steel pipes with a diameter of 1m and a wall thickness of 16mm are used for anti-corrosion treatment of the steel pipes.

[0097] The calculation method given by this application is calculated as follows:

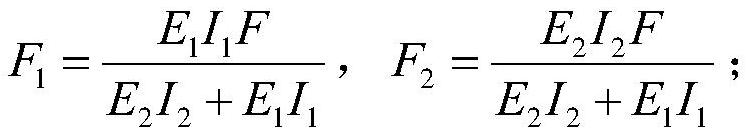

[0098] Steel pipe resists horizontal force:

[0099]

[0100] Pile core concrete resists horizontal force:

[0101]

[0102] At this time, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com