A spinning machine for polypropylene processing

A polypropylene and spinning machine technology, applied in the polypropylene field, can solve the problems of disconnection and large internal space of the spinneret, and achieve the effect of avoiding cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

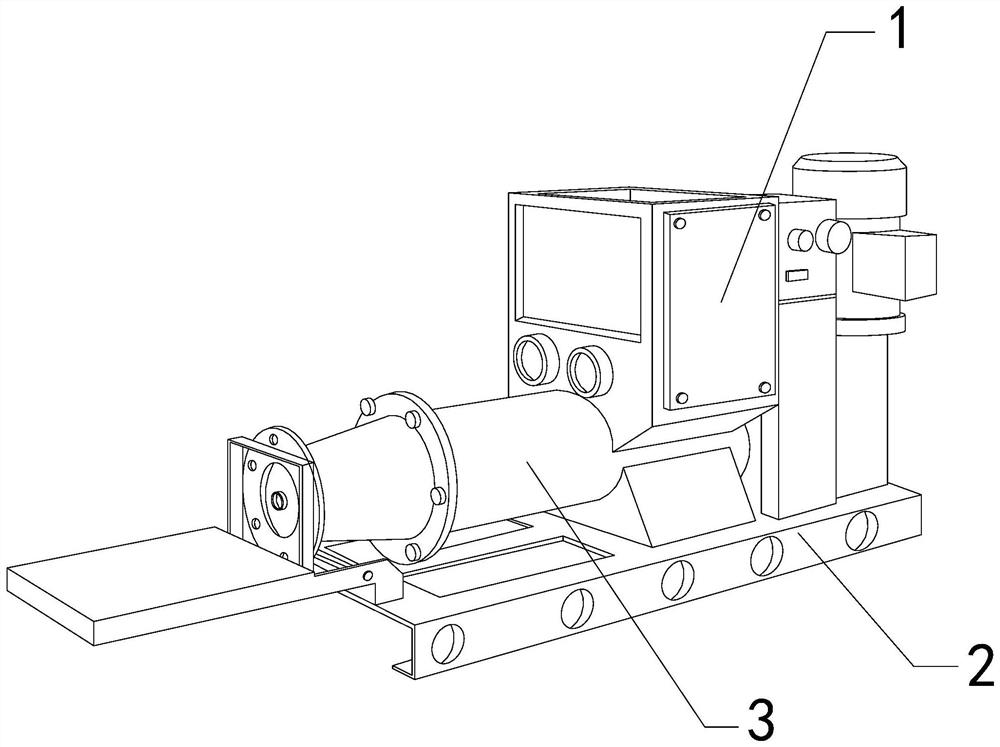

[0026] For example figure 1 -example Figure 5 Shown:

[0027] The present invention provides a spinning machine for polypropylene processing. The internal position of the heating bucket 1; the spinneret tube 3 includes a middle fixing rod 31, an outer tube 32, a take-out mechanism 33, and a pre-pipe 34. The middle fixing rod 31 is embedded in the right position of the inner wall of the outer tube 32. , the take-out mechanism 33 is movably engaged with the left end of the middle fixing rod 31 , and the right side of the front pipe 34 is abutted with the left side of the middle fixing rod 31 .

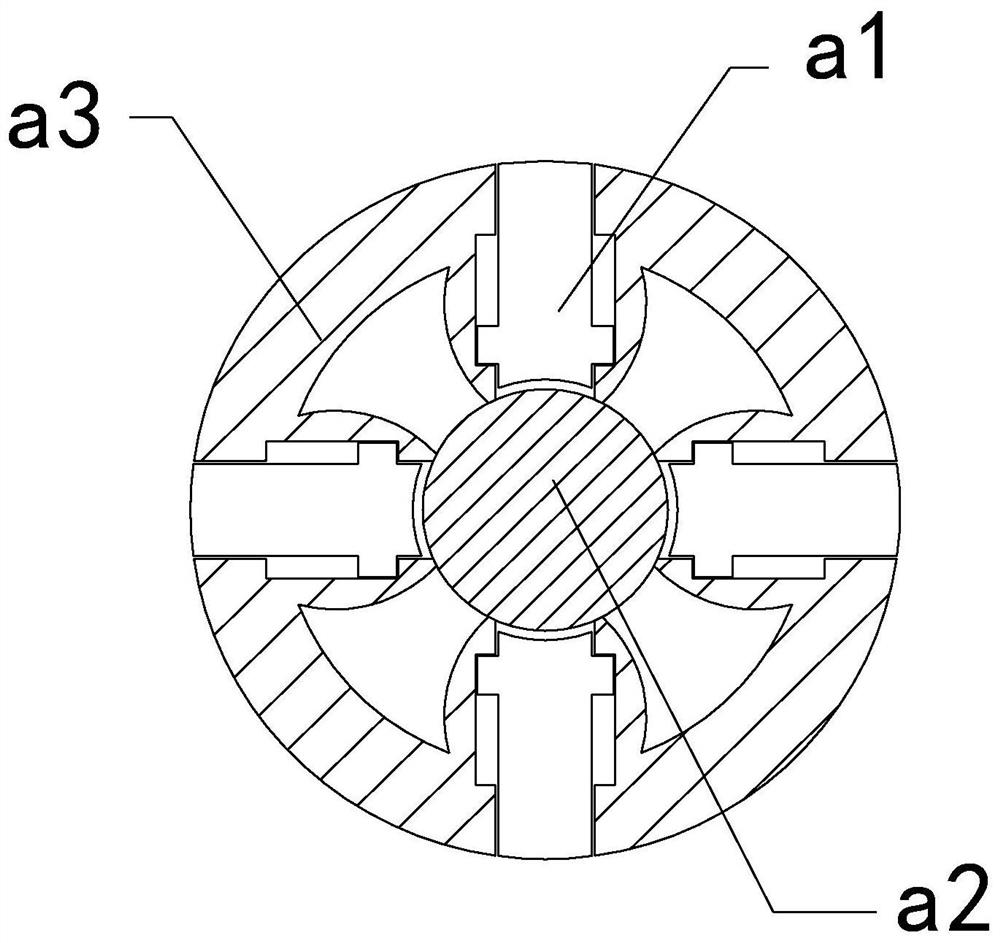

[0028] The take-out mechanism 33 includes an outrigger rod a1, a middle solid block a2, and an outer ring a3, the outer extension rod a1 and the inside of the outer ring a3 are distributed in parallel, and the middle solid block a2 is fixed on the outer ring a3 The inner center position of the outriggers a1 is provided with four, and evenly distributed in a circle inside the outer ri...

Embodiment 2

[0034] For example Image 6 -example Figure 8 Shown:

[0035] The outer ring a3 includes an outer expansion plate c1, a fixed frame c2, a middle block c3, and an elastic piece c4. The outer expansion plate c1 is connected to the outer side of the fixed frame c2 through the elastic piece c4, and the fixed frame c2 It is fixed at the position of the outer surface of the neutral block c3. There are four outer expansion plates c1, and they are evenly distributed in a circle on the outside of the fixed frame c2. The force generated by the rotation of the mechanism can make the outer expansion plates c1 Extending out along the elastic sheet c4, and then pulling the outer expansion plate c1 by the elastic sheet c4, the inner side of the outer expansion plate c1 can generate impact vibration to the outer side of the fixed frame c2.

[0036] The outer expansion plate c1 includes a base plate c11, a vibration ball c12, an outer contact plate c13, and a contact reduction groove c14. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com