Heat dissipation air inlet cabin and unmanned aerial vehicle applying same

A technology of air inlet and air inlet channel, which is applied in the cooling system of aircraft parts, power plant, transportation and packaging, etc., which can solve the problems of increased flight resistance, impact on the flight performance and safety of the whole aircraft, unstable flow, etc., and achieve The effect of uniform flow velocity distribution, good air intake efficiency, and stable gas flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

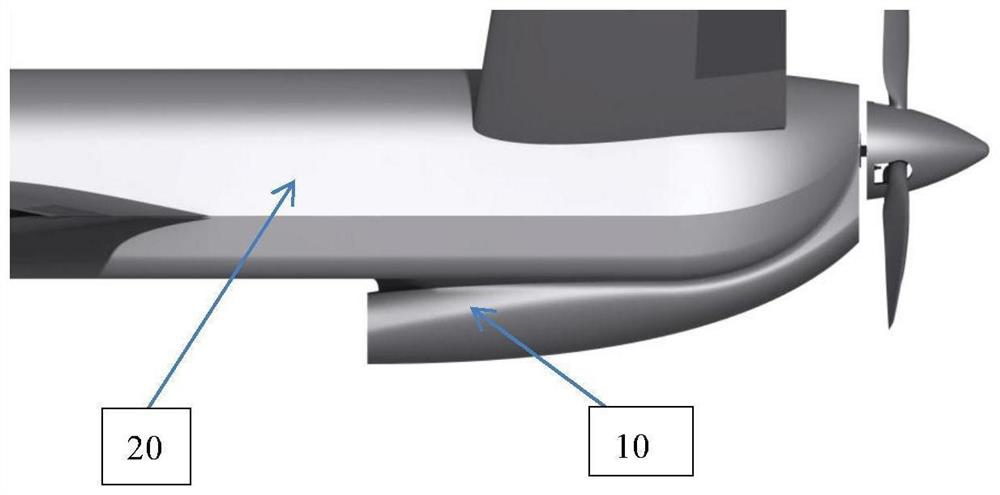

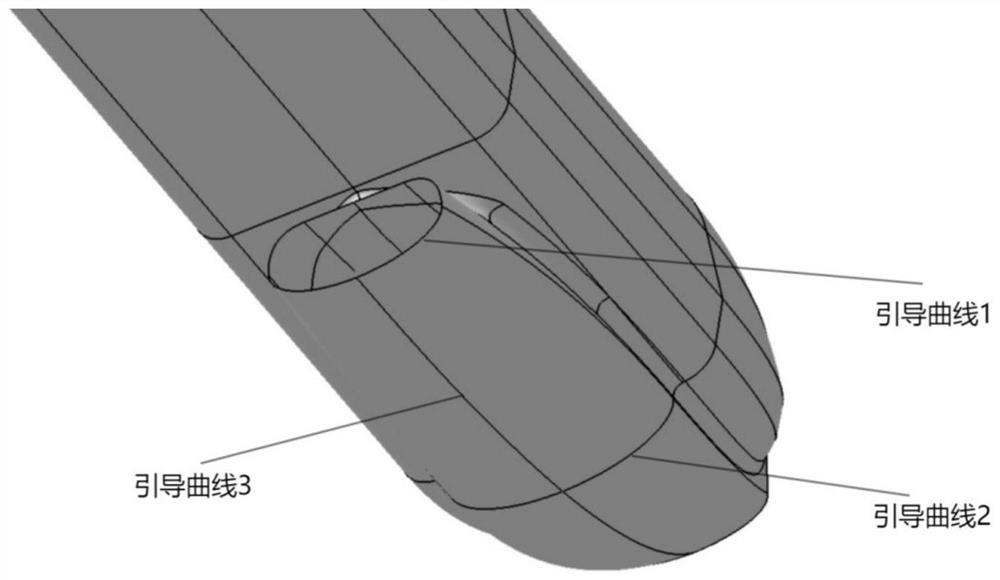

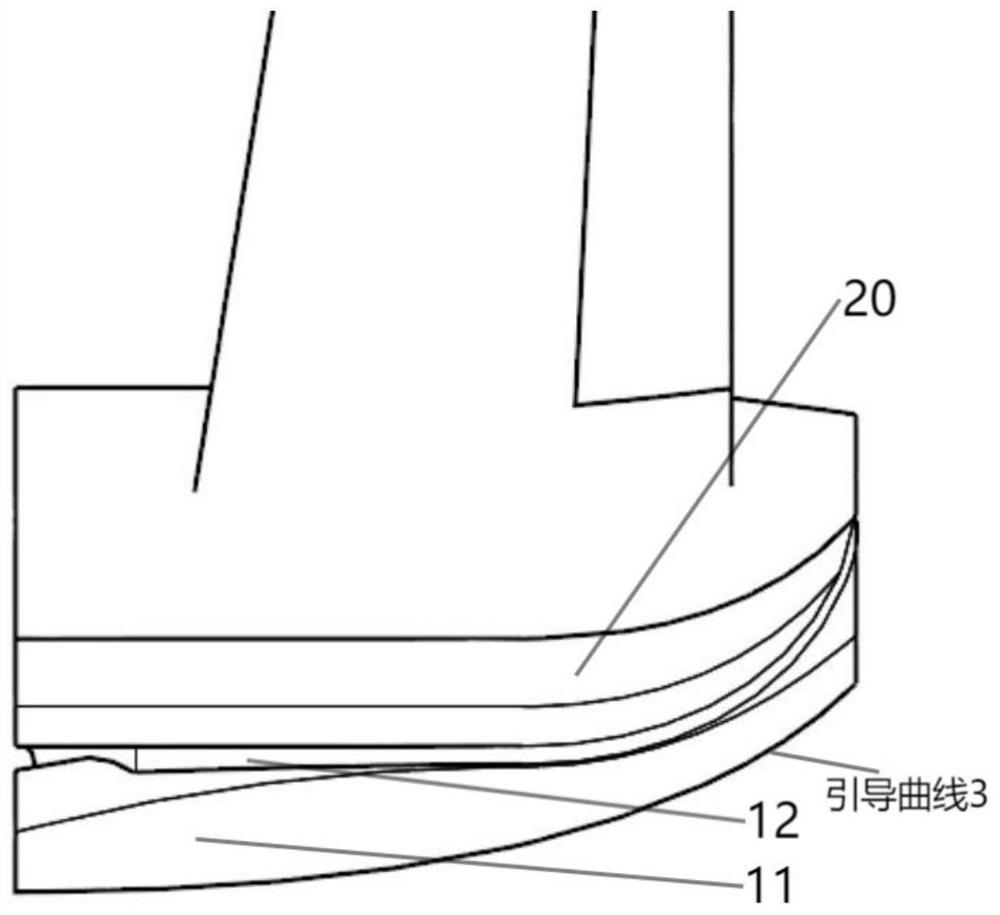

[0043] The invention provides a heat dissipation air intake cabin and an unmanned aerial vehicle using the same. In the heat dissipation air intake cabin, through the unique design of the curved surface of the outer bottom of the cabin outer cover, the shape of the heat dissipation air inlet channel, and the boundary layer shunt mechanism, etc., it can It achieves the purpose of reducing the additional resistance brought by the installation of the heat dissipation air intake cabin, ensuring the stability of the gas flow rate in the heat dissipation air intake channel, and improving the air intake efficiency.

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be understood that these embodiments are provided only so that the invention will satisfy legal requiremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com