A kind of manufacturing process of solid wood fireproof board

A manufacturing process and fireproof board technology, which is applied in the direction of manufacturing tools, wooden veneer joints, wood layered products, etc., can solve the influence of the tightness of the combination of decorative paper and bottom paper, and the production of decorative fireproof materials is time-consuming and difficult. Take advantage of the flame retardant effect and other issues to achieve the effects of easy mass production, strong decoration, and reduced processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

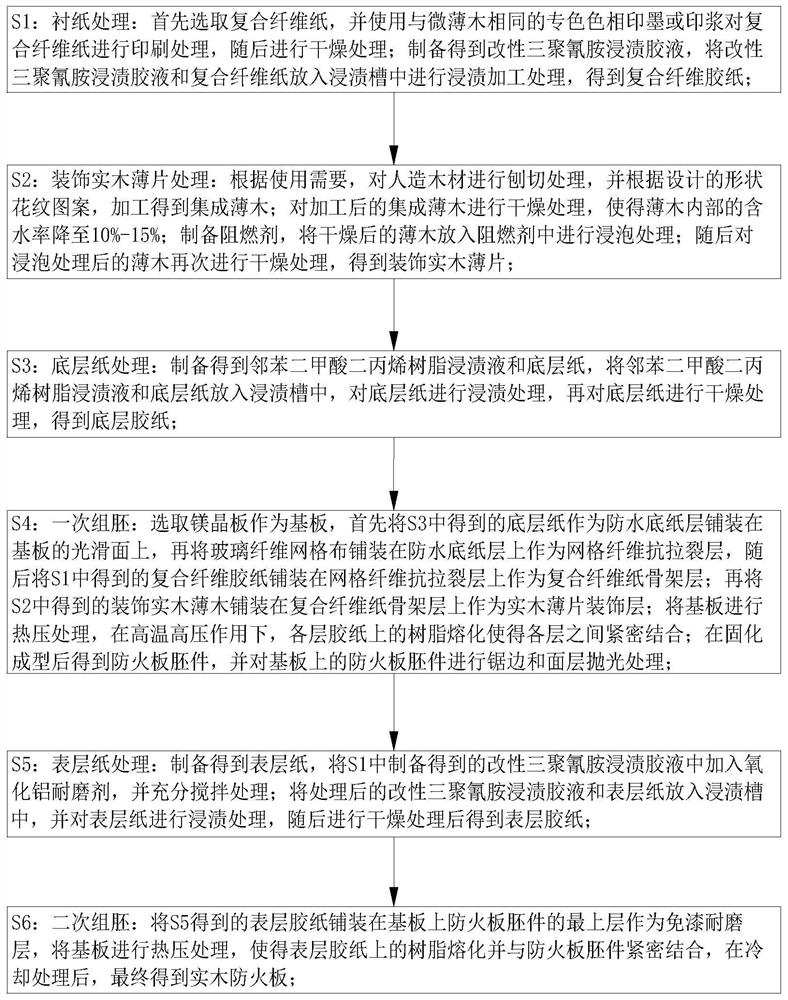

Method used

Image

Examples

Embodiment approach

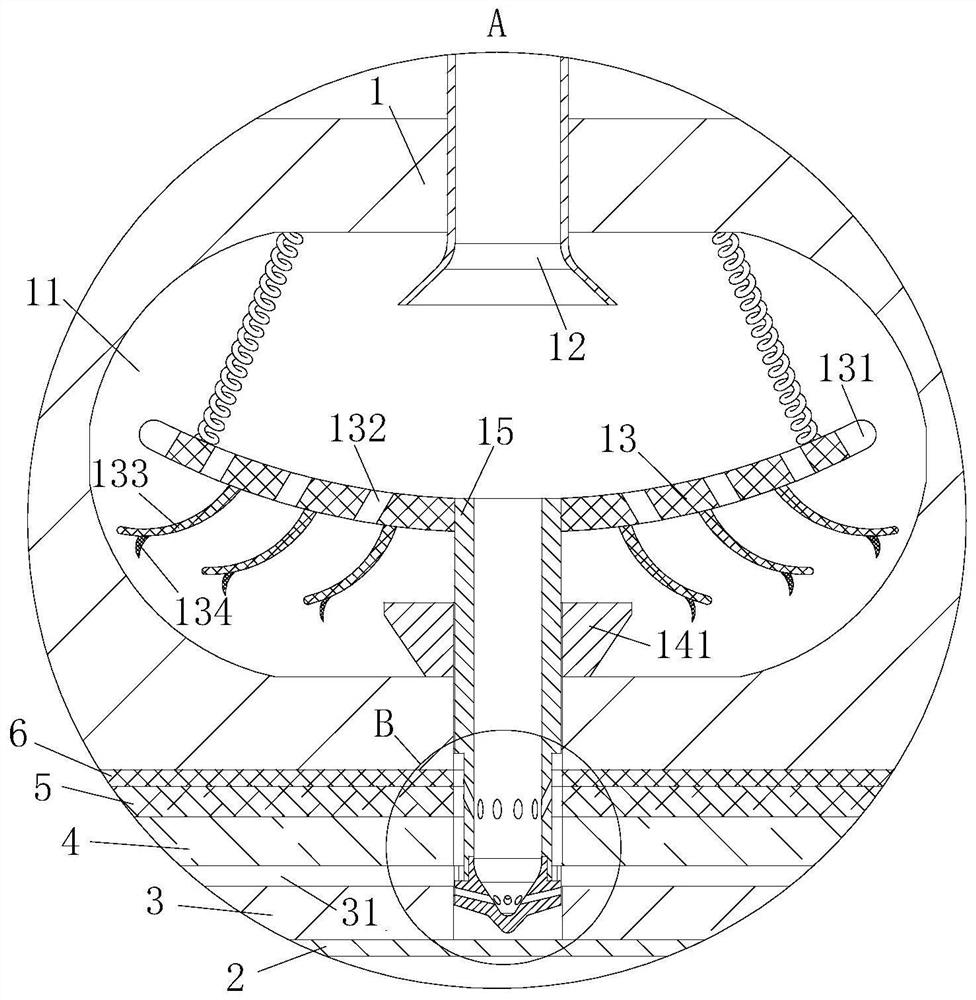

[0045] As an embodiment of the present invention, the bottom surface of the fire prevention chamber 11 is provided with a limit block 141 near the top of No. Groove 151; when the bottom surface of the No. 1 plate 13 is in contact with the top of the limiting block 141, the bottom of the No. 1 annular groove 151 protrudes into the outside, and the top of the No. 1 annular groove 151 is located above the solid wood veneer decorative layer 3.

[0046] During operation, when the No. 1 board 13 moves under the impact of the flame-retardant gas, the lower surface of the middle part of the No. 1 board 13 that continues to move contacts with the upper surface of the bottom of the limit block 141, so that the No. 1 board 13 is limited Function: At this time, there is a gap between the lower surface of the No. 1 plate 13 and the bottom surface of the fireproof chamber 11, so that the dry powder fire extinguishing agent at the bottom of the fireproof chamber 11 is in the gap between the N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com