Non-welding connection construction method for PE natural gas pipes

A construction method and technology for natural gas pipes, which are applied in the direction of pipeline connection arrangement, hose connection device, pipe/pipe joint/pipe fitting, etc., can solve the complex operation process and welding technology, the operation method cannot be operated, and the pipeline is twisted or knotted. and other problems, to achieve the effect of prolonging the construction operation season, improving the operation efficiency, and improving the connection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] like Figure 3-Figure 5 As shown, the non-welded connection construction method of PE natural gas pipe of the present invention comprises the following steps:

[0056] S10, perform section cleaning and chamfering operations on the two sections of PE natural gas pipelines 1 that need to be connected;

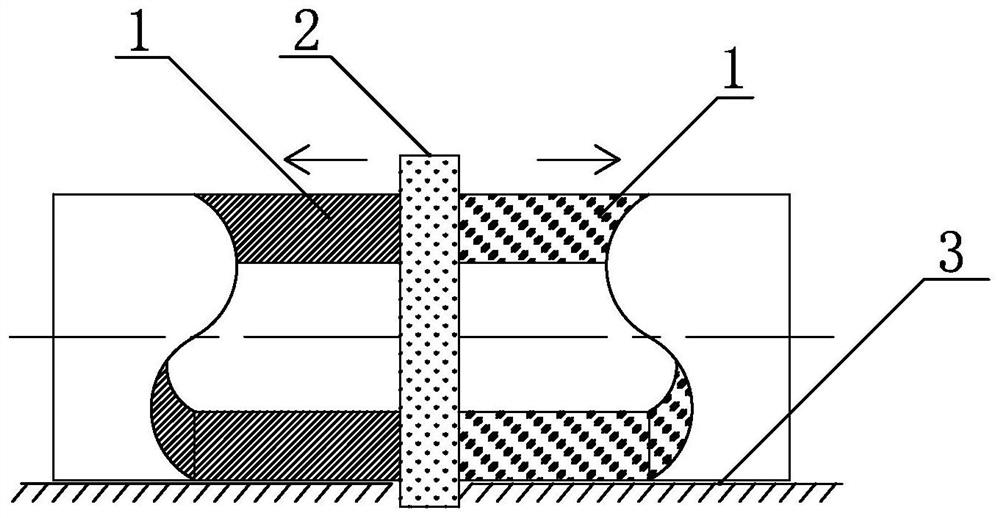

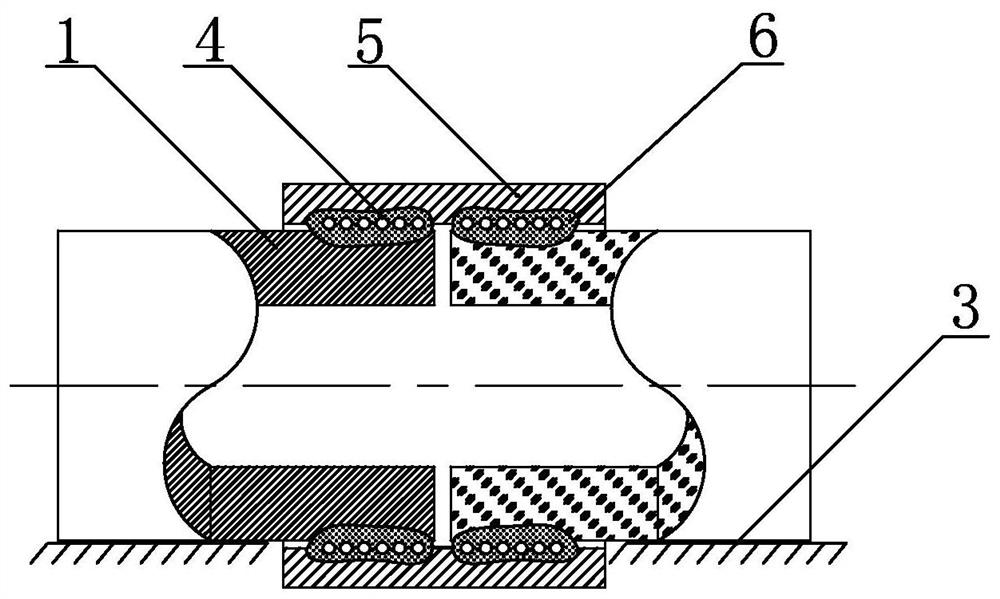

[0057] S20, docking and installing the external pressing part and the sealing support part 8, the external pressing part is located outside the sealing supporting part 8, and the inner diameter of the external pressing part is slightly smaller than the outer diameter of the PE natural gas pipeline 1, so as to ensure that the PE natural gas pipeline can be sealed after installation. 1 There is a clamping force to prevent the PE natural gas pipeline 1 from withdrawing from the sealing support 8 under the action of tension;

[0058] S30, immerse the two sections of PE natural gas pipeline 1 in hot water at 95-100°C for 3-5 minutes, so that the two sections of PE natural gas ...

Embodiment 2

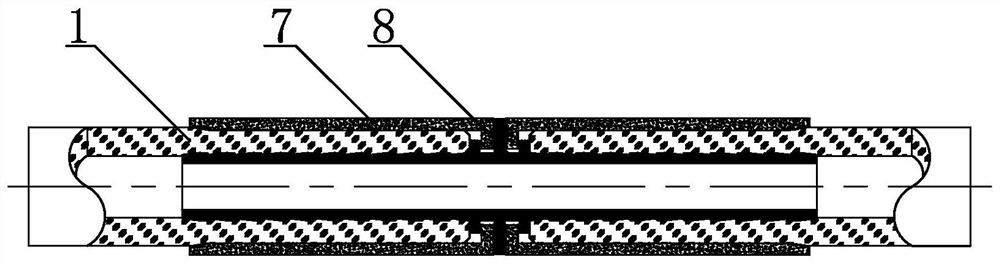

[0067] The difference between this embodiment and Embodiment 1 is that the inner surface of the compression sleeve 7 is processed like Image 6 Protrusion 9 as shown or as Figure 7 The structure of the barb 10 shown is to increase the tightness of the connection between the PE natural gas pipeline 1 and the compression sleeve 7 and the sealing support 8, increase the friction between the three, and prevent the PE natural gas pipeline 1 from being pulled out.

[0068] The structure of the protrusion 9 or the barb 10 can be directly manufactured when the compression sleeve 7 is manufactured, or secondary processing can be performed after the compression sleeve 7 is manufactured.

Embodiment 3

[0070] The difference between this embodiment and embodiment 1 is: as Figure 8 As shown, the external pressing part is a cylindrical PE structure 11, and the cylindrical PE structure 11 is made of heat-shrinkable material. The outer wall of the sealing support 8 is only provided with a plurality of sawtooth structures on both sides, and the middle part of the outer wall of the sealing support 8 does not need to process the main baffle and the auxiliary baffle.

[0071] In this embodiment, the non-welded connection construction method of PE natural gas pipes includes the following steps:

[0072] S10, perform section cleaning and chamfering operations on the two sections of PE natural gas pipelines 1 that need to be connected;

[0073] S20, immerse the two sections of PE natural gas pipeline 1 in hot water at 95-100°C for 3-5 minutes, so that the two sections of PE natural gas pipeline 1 appear softened, but the PE natural gas pipeline 1 cannot be obviously deformed;

[0074...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com