Forming method of thermoplastic composite material with integrated sandwich structure

A molding method and technology of composite materials, applied in the direction of coating, etc., can solve the problems of difficult operation, high viscosity, and high molding temperature of special engineering plastics, and achieve the effects of simple process, reduced production cost, and reduced equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for forming a glass fiber reinforced polyphenylene sulfide integrated sandwich structure composite material, comprising the following steps:

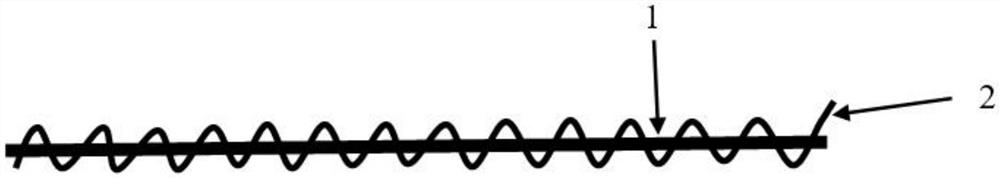

[0023] (1) The 66tex continuous E-glass fiber yarn is used as the "core" shaft yarn 1 and the "skin" polyphenylene sulfide (PPS) yarn 2 is compounded through special textile equipment to obtain a "skin-core structure" wrapped yarn ;

[0024] (2) Weaving the wrapped yarn prepared in step (1) into an integrated hollow structure three-dimensional fabric prefabricated body with a thickness of 8 mm by using a special special loom;

[0025] (3) Place the above-mentioned three-dimensional fabric prefabricated body on a flat vulcanizing machine for double-sided heating at a heating temperature of 325°C to melt the thermoplastic resin tow, wrap and infiltrate the reinforcing fiber tow;

[0026] (4) Finish the four sides of the hollow fabric so that the three-dimensional fabric prefabricated body can stand well and have a uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com