Rapid rubber band cutting device for rubber band processing

A rubber band and fast technology, which is applied in metal processing and other directions, can solve the problem of single size of the cutting ring, and achieve the effect of easy replacement, convenient material removal, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

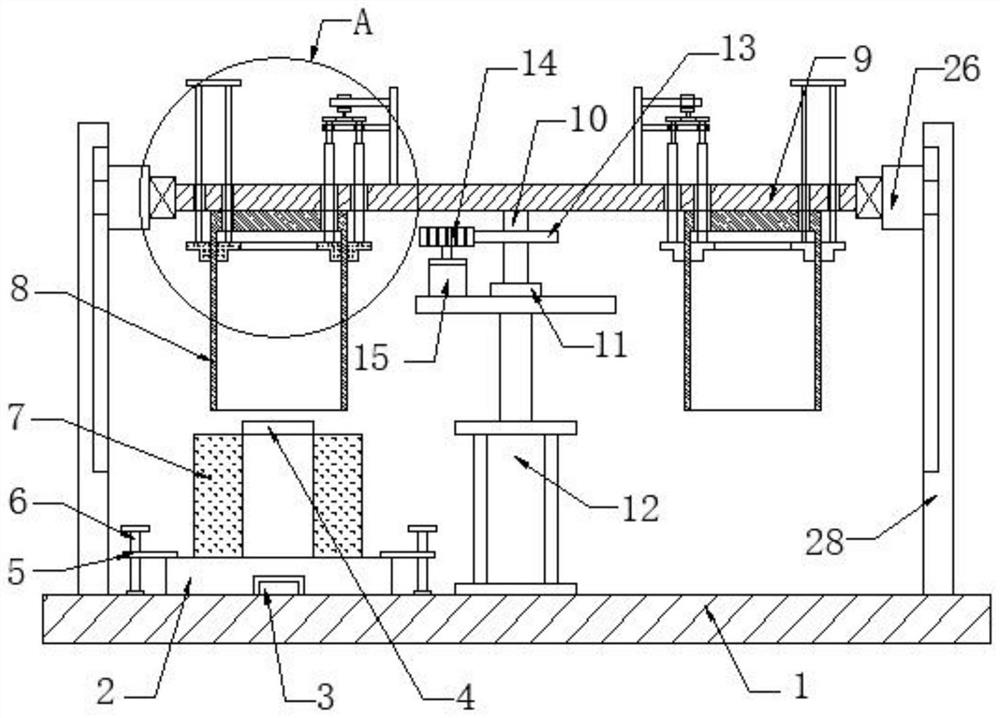

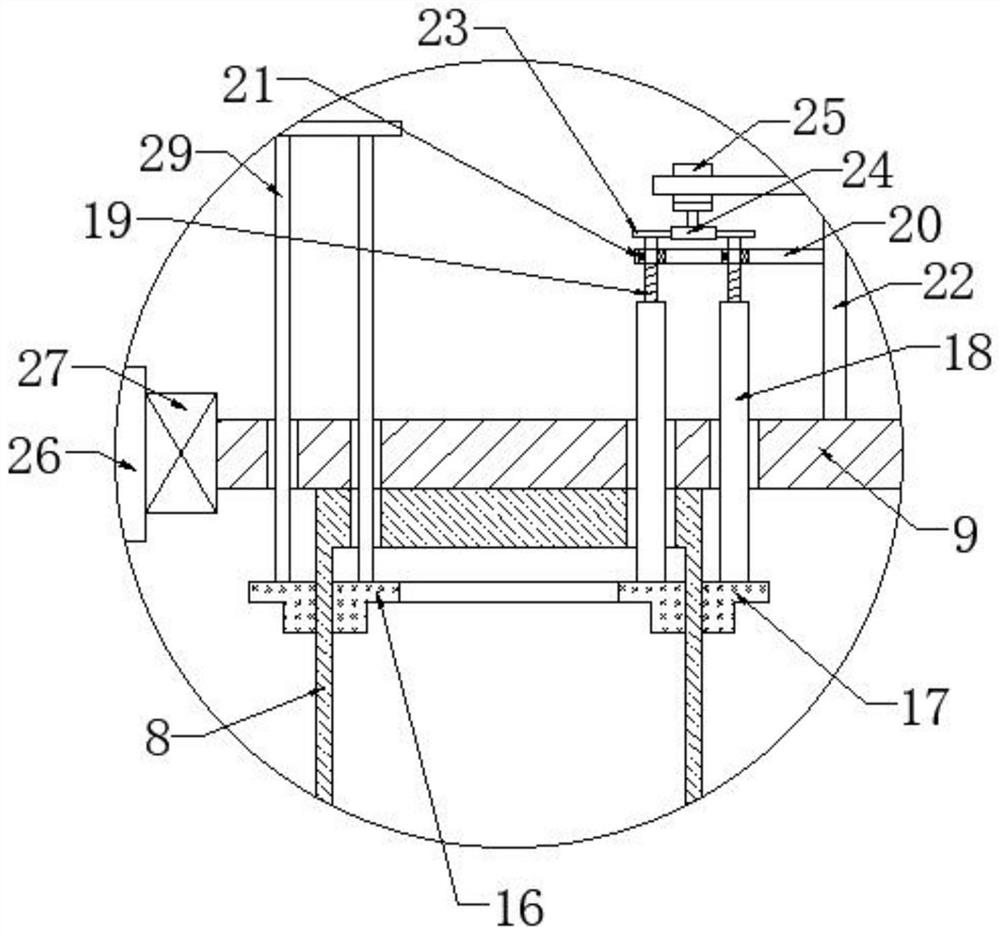

[0031] refer to Figure 1-5 , a fast loop cutting device for rubber band processing, comprising a base 1, a fixed seat 2 and a sleeve rod 4, the upper end of the base 1 is provided with a fixed seat 2 on the left side, and the upper end of the base 1 is provided with a positioning rod 3 corresponding to the fixed seat 2, and the positioning rod 3 Inserted on the fixed seat 2, the middle part of the upper end of the fixed seat 2 is provided with a sleeve rod 4, the left and right sides of the upper end of the fixed seat 2 are provided with a pressure plate 5, the lower end of the pressure plate 5 is fitted with the fixed seat 2, and the pressure plate 5 is provided with a rotating rod 6. The rotating rod 6 is rotated to connect the base 1. The sleeve rod 4 is covered with a cylindrical rubber 7. When the cylindrical rubber 7 needs to be replaced, the rotating rod 6 drives the pressure plate 5 to rotate, so that the pressure plate 5 is away from the fixed seat 2. Just pull out t...

Embodiment 2

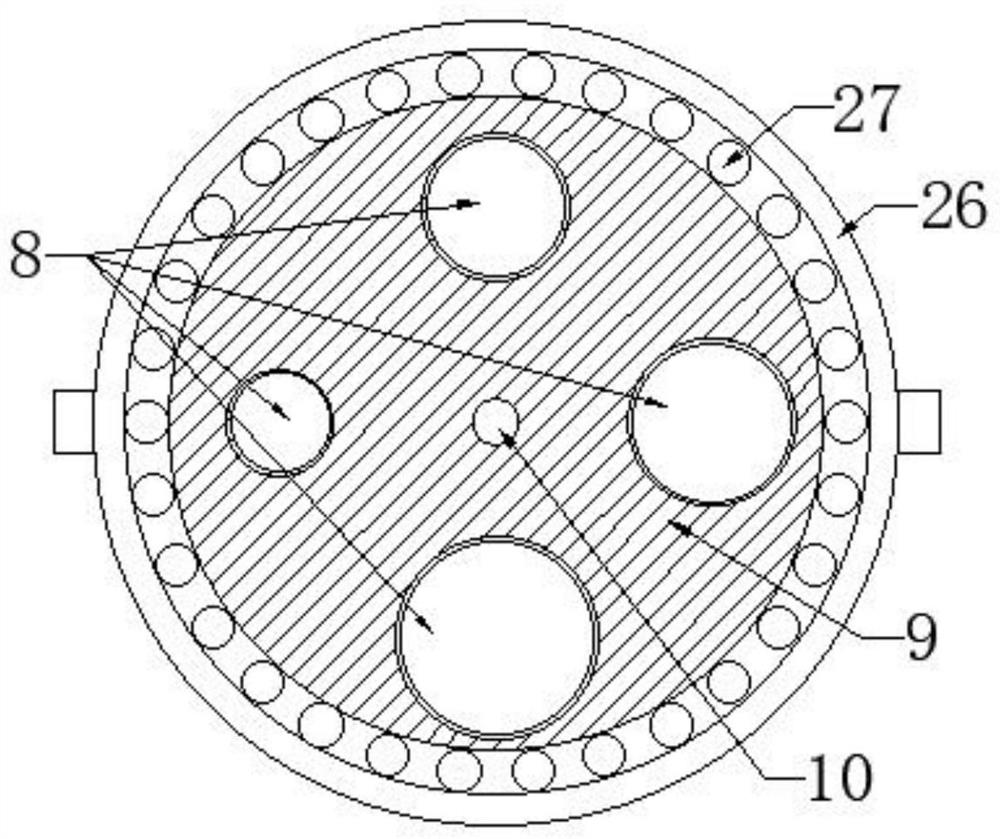

[0033] Such as Figure 1-5 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a fixed sleeve 26 is provided on the outer side of the support plate 9, a bearing three 27 is provided at the connection between the support plate 9 and the fixed sleeve 26, and the support plate 9 is rotatably connected to the fixed sleeve 26. , the left and right ends of the fixed cover 26 are all provided with connecting plates 28, the lower ends of the connecting plates 28 are fixedly connected to the base 1, and one end of the connecting plates 28 close to each other is provided with a chute corresponding to the fixed cover 26, and the fixed cover 26 is slidably connected with the connecting plate 28, When the support plate 9 moves up and down to work, the connecting plate 28, the fixed sleeve 26 and the three bearings 27 provided play a stabilizing effect when the support plate 9 works.

[0034] The present invention facilitates cutting out rubber bands with different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com