Paint surface polishing device for automobile maintenance

A technology for automobile maintenance and painting, which is used in grinding drive devices, grinding/polishing safety devices, and grinding machines, etc. It can solve the problems of inability to meet the needs of use, inconvenient dust extraction and filtration, and high labor intensity, and achieve reasonable design, Easy to operate and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

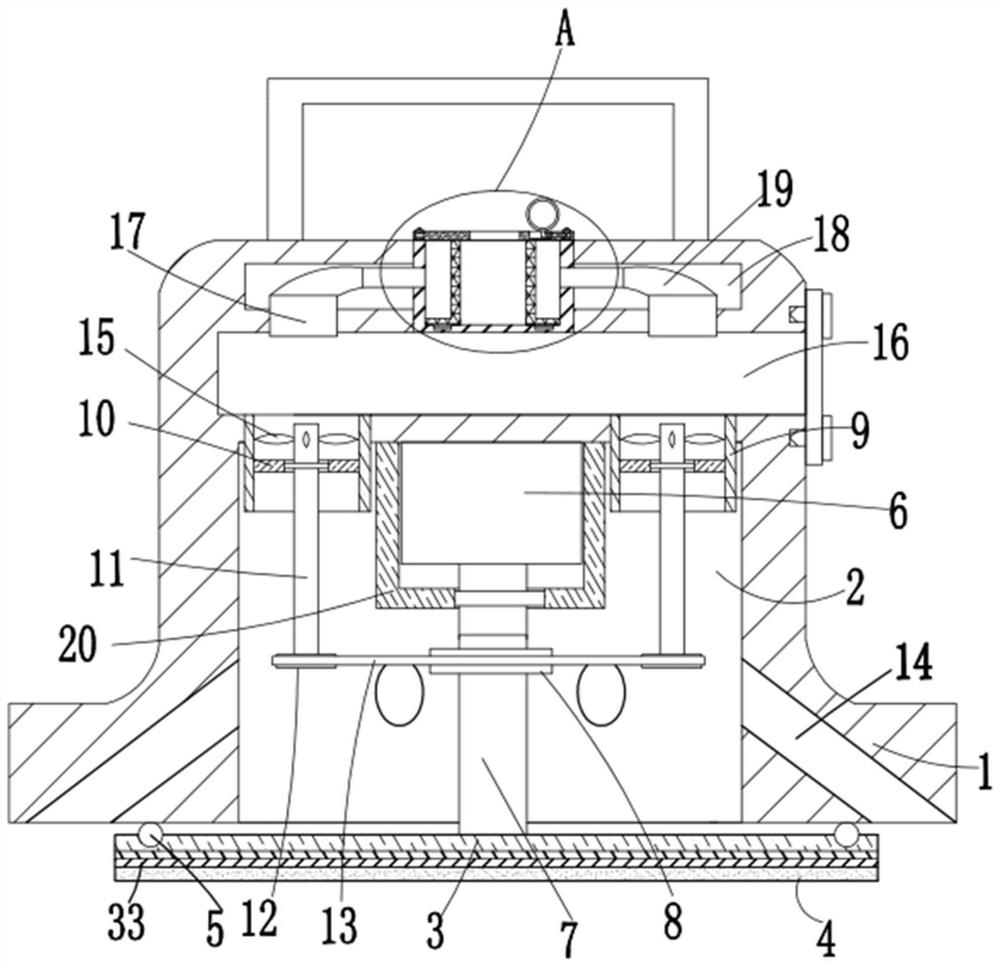

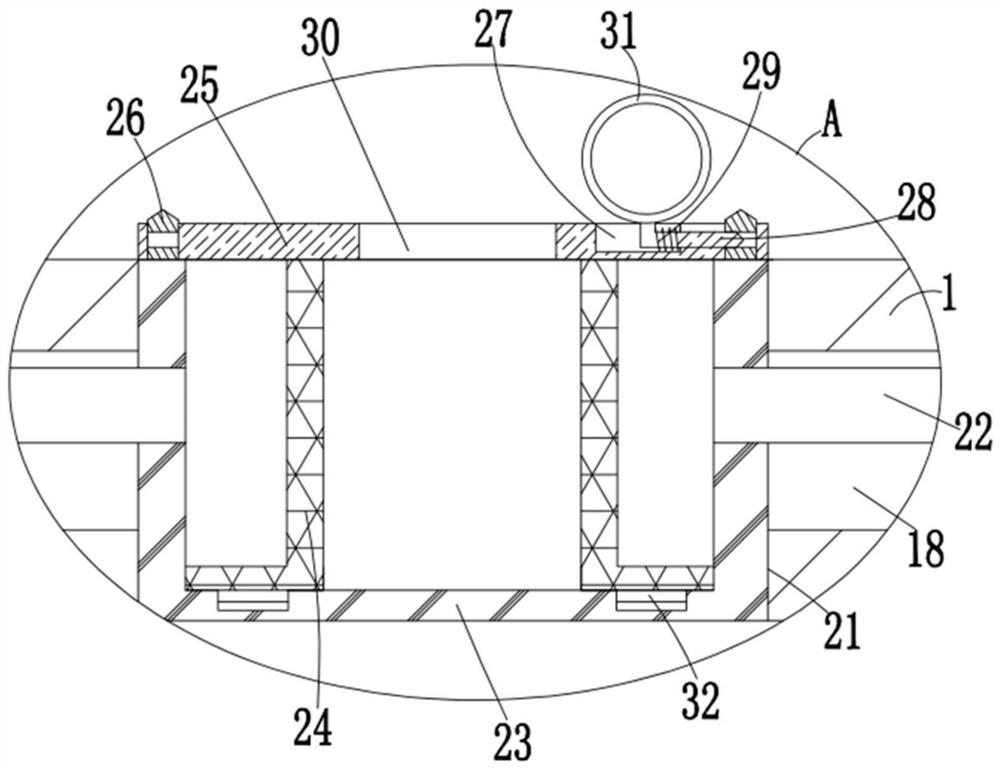

[0024] refer to Figure 1-4 , the present embodiment proposes a paint surface grinding device for automobile maintenance, including a mounting base 1, a polishing paper 4 is provided below the mounting base 1, a U-shaped handle is fixedly connected to the top of the mounting base 1, and a Disc 3, the bottom of disc 3 is bonded and fixed to the top of grinding paper 4, and the top of disc 3 is annularly embedded with a plurality of balls 5, and balls 5 are in rolling contact with the bottom of mounting seat 1, and the bottom of mounting seat 1 A first groove 2 is provided, and an automatic grinding and dust-absorbing mechanism is provided in the first groove 2, and a filtering, collecting, and fast-fetching mechanism matched with the automatic grinding and dust-absorbing mechanism is provided on the mounting base 1. The present invention is reasonable in design and convenient in operation. The drive motor 6 drives the grinding paper 4 for automatic rotation and grinding, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com