Combination function dedicated fiber humidifier

A humidifier and fiber technology, applied in the direction of spraying/spraying textile materials, etc., can solve the problems of uneven humidity, pollution of the operating environment, fast evaporation speed, etc., and achieve uniform humidity, improve the operating environment, and large humidification surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

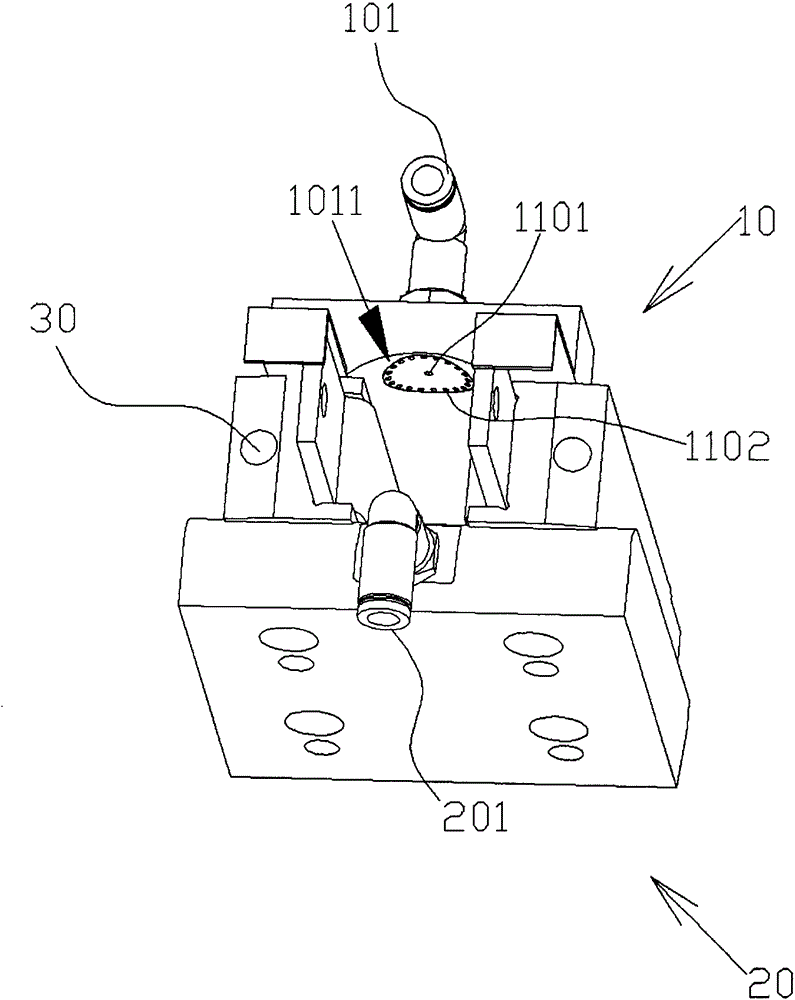

[0021] figure 1 with figure 2 Schematically shows a combined function dedicated fiber humidifier according to an embodiment of the present invention.

[0022] Such as figure 1 with figure 2 As shown, the combined function special fiber humidifier for fully wetting products provided by the present invention includes: an upper humidifying mechanism 10 and a lower humidifying mechanism 20, and a product passage 12 between the upper humidifying mechanism 10 and the lower humidifying mechanism 20; The humidifying mechanism 10 is provided with an upper humidifying channel 101, and the upper humidifying channel 101 is provided with an upper humidifying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com