Building waste smashing device for building construction

A technology for construction waste and construction, which is applied in grain processing, spring/shock absorber, vibration suppression adjustment, etc. It can solve the problems of wasting financial and material resources, complicated processing, and low crushing efficiency, so as to reduce adverse effects and ensure the processing effect , Improve the effect of crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

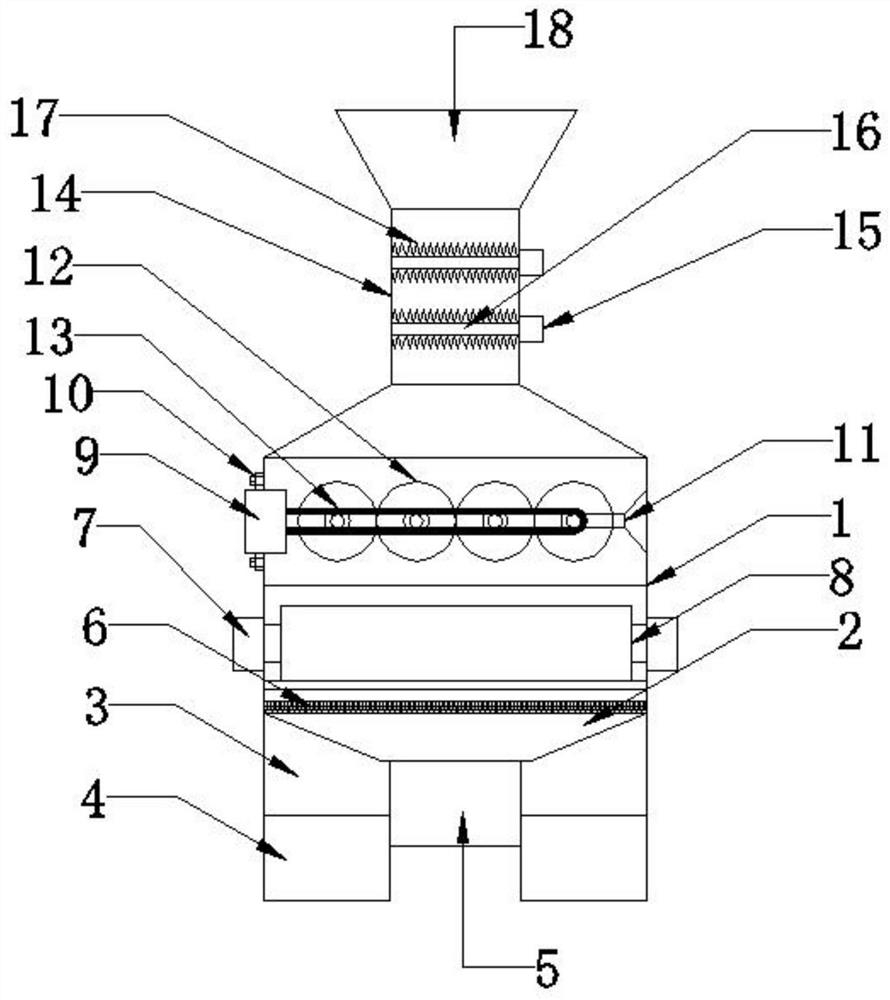

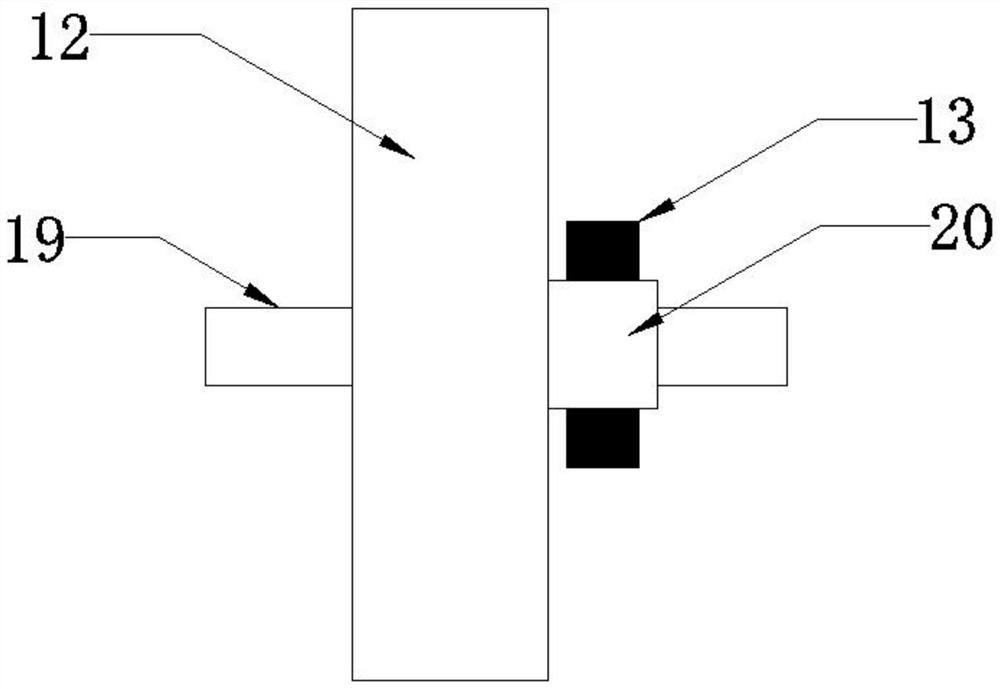

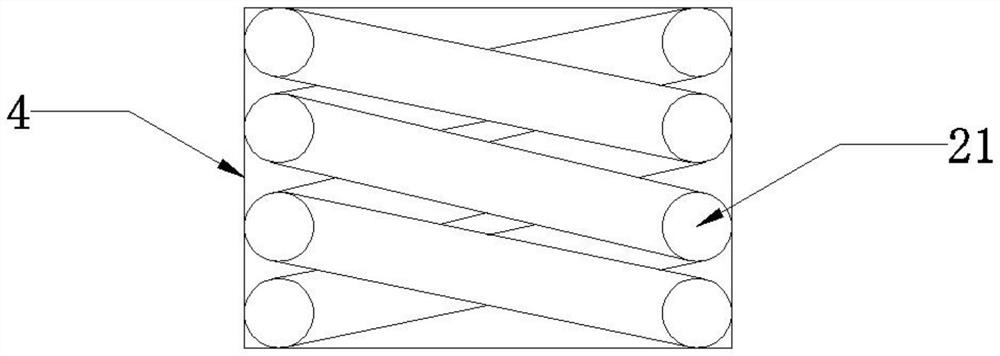

[0022] see Figure 1-4 , an embodiment provided by the present invention: in order to achieve the above object, the present invention provides the following technical solutions: a construction waste crushing device for building construction, comprising a crushing main body 1, the bottom of the crushing main body 1 is provided with a bottom chute 2, the bottom Both ends of the bottom of the chute 2 are evenly and symmetrically distributed with bottom legs 3, and the bottom of the bottom legs 3 is provided with shock-absorbing legs 4, and two groups of shock-absorbing feet 4 are arranged in parallel, and the top of the shock-absorbing feet 4 A shock absorbing spring 21 is provided and the top of the shock absorbing spring 21 is fixedly connected to the bottom leg 3. The shock absorbing spring 21 provided inside the shock absorbing leg 4 can effectively reduce the adverse effects of the vibration environment on the device. , the center position of the bottom of the bottom chute 2...

Embodiment 2

[0025] refer to Figure 5 As shown, the difference from Embodiment 1 is that the shock absorbing assembly is used to replace the shock absorbing spring member 21, and the shock absorbing assembly includes an adapter seat 1 43, an adapter seat 2 44, a guide rod 45 and a sliding seat 46. A guide rod 45 arranged horizontally is fixedly installed on the shock-absorbing foot 4, and two sliding seats 46 with opposite moving directions are slidably arranged on the guide rod 45, and a return spring 47 is arranged between the two sliding seats 46. And the two ends of back-moving spring one 47 are fixedly installed with corresponding sliding seat 46 respectively, and connecting rod 48 is all rotatably installed on two described sliding seats 46, and two described connecting rods 48 are eight-shaped settings and are far away from sliding seat 46 One end of each is rotatably mounted on the bottom leg 3, the return spring one 47 is sleeved on the outside of the guide rod 45, the adapter on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com